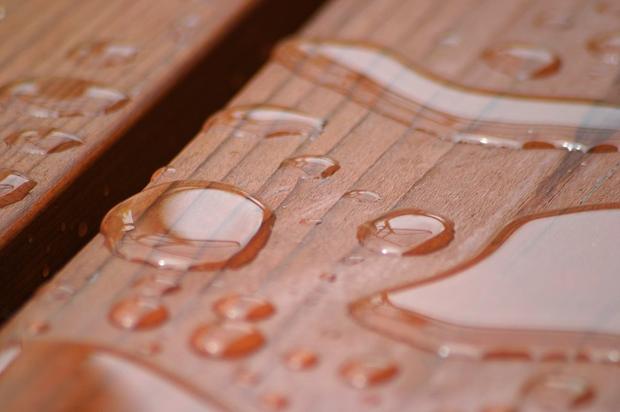

DIY Garden Roof – Quick Epoxy Fix?

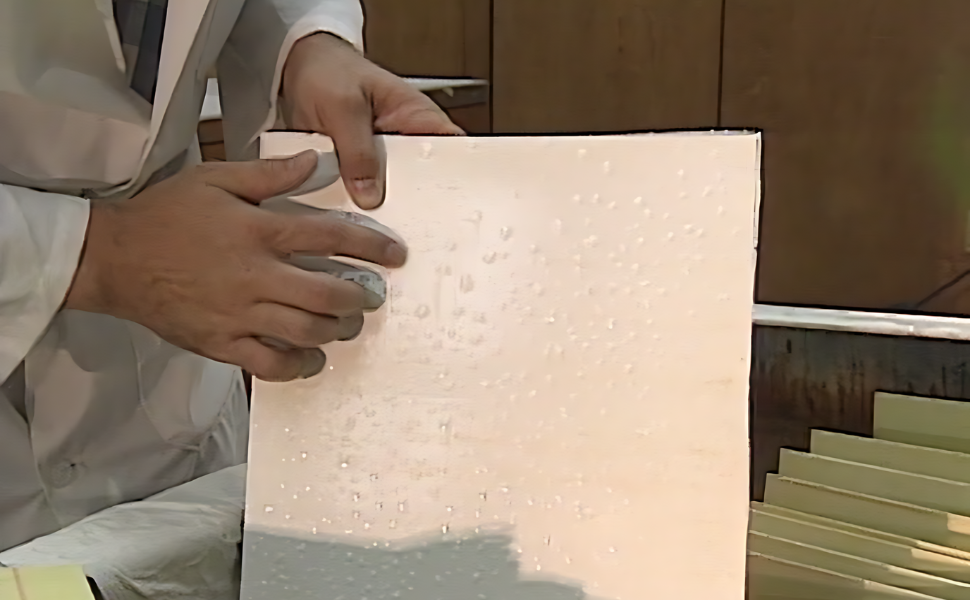

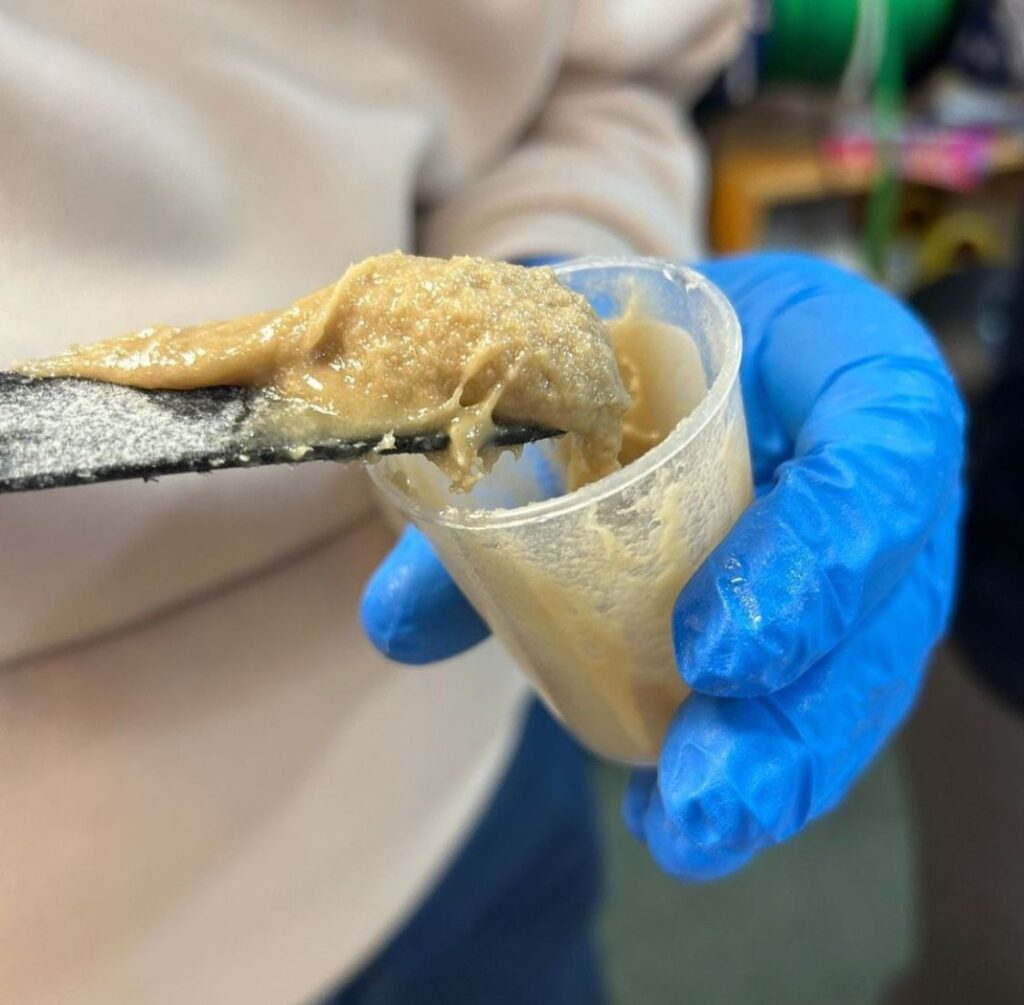

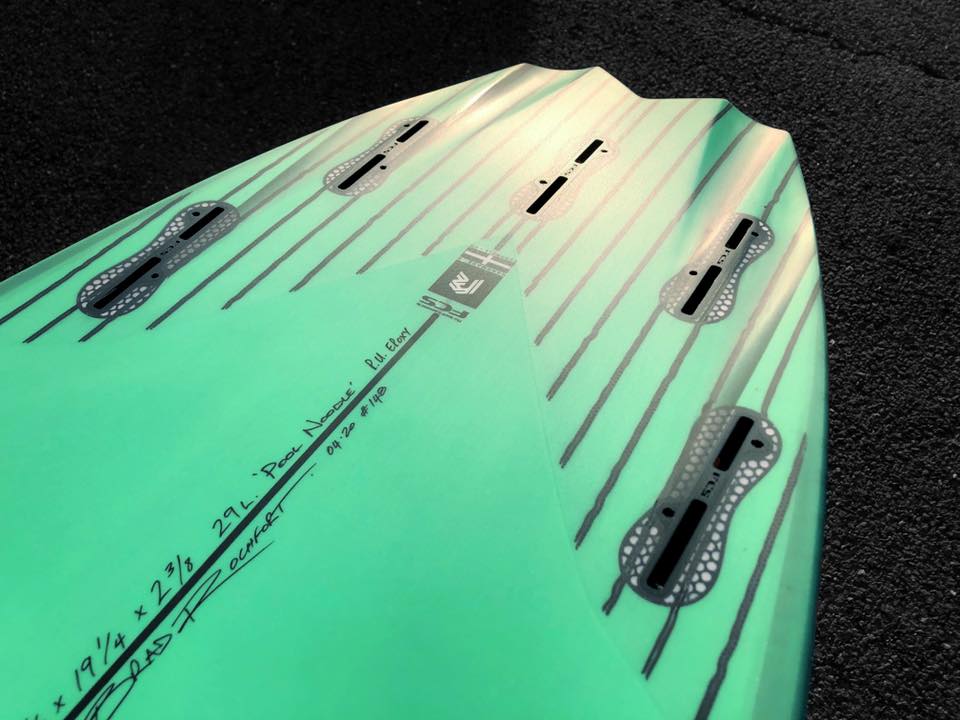

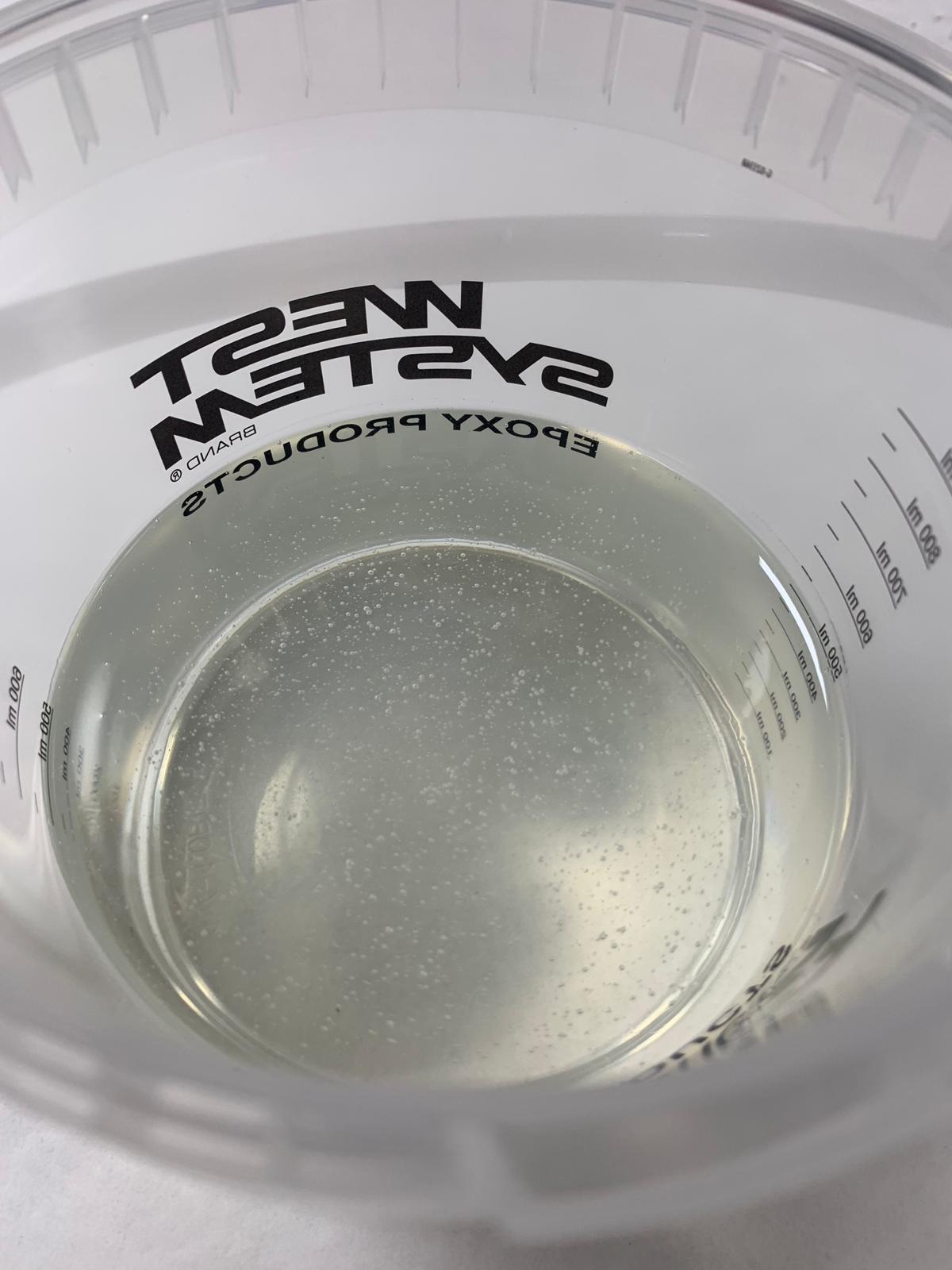

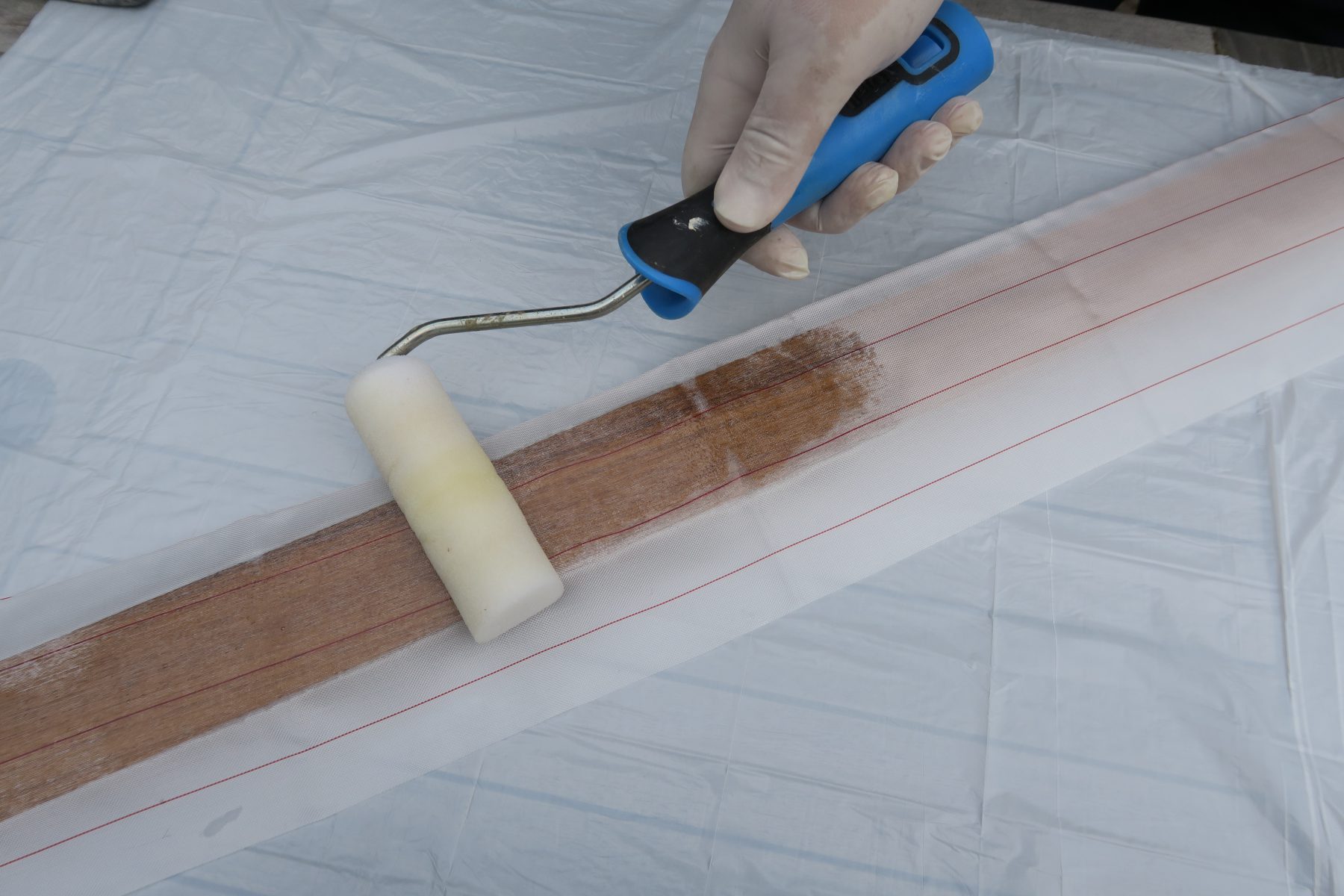

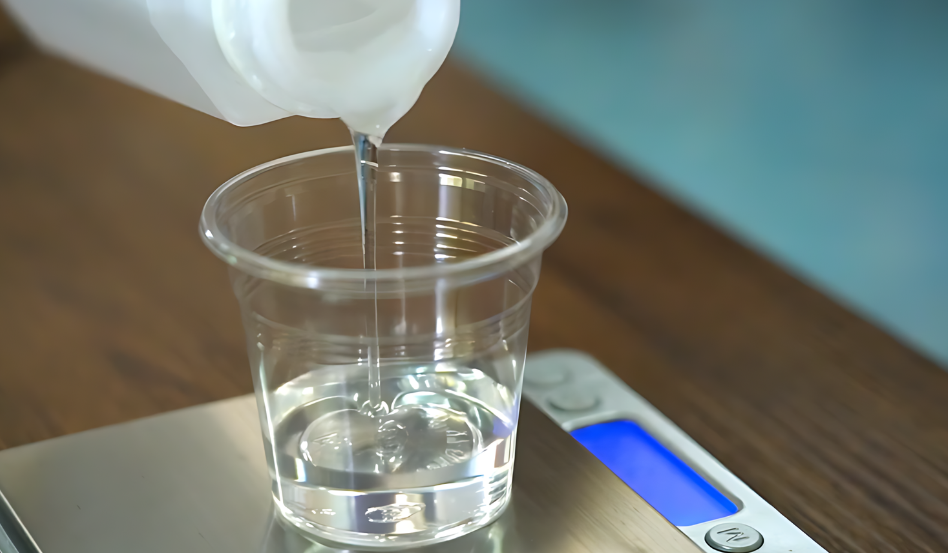

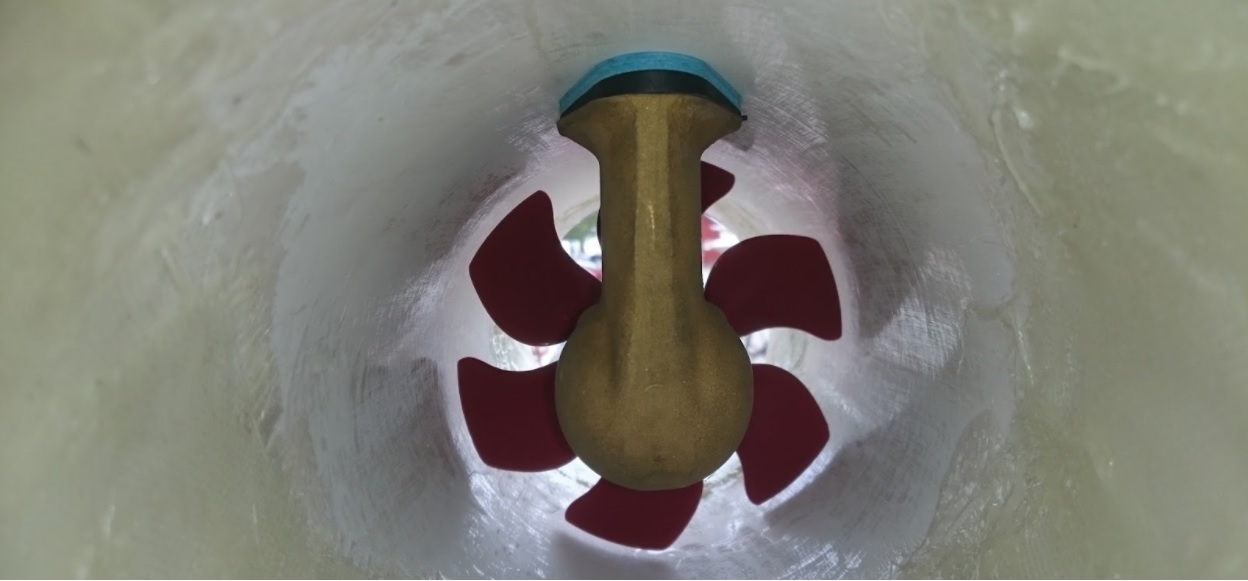

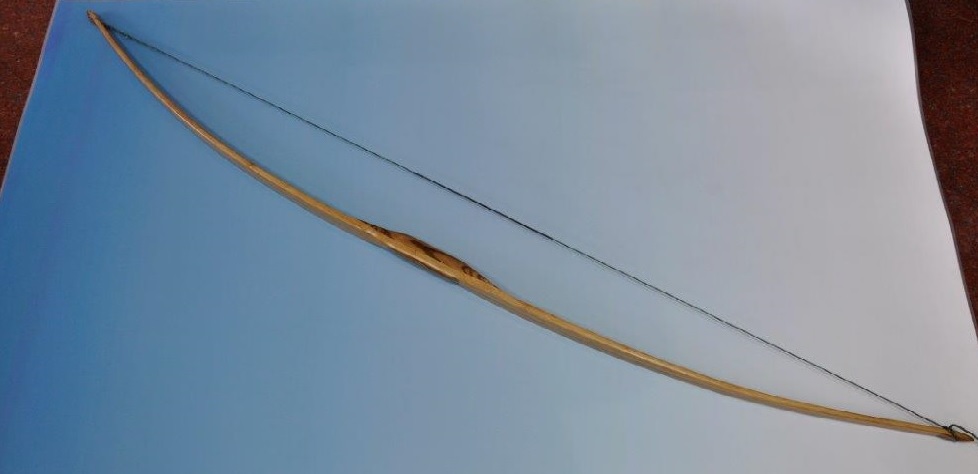

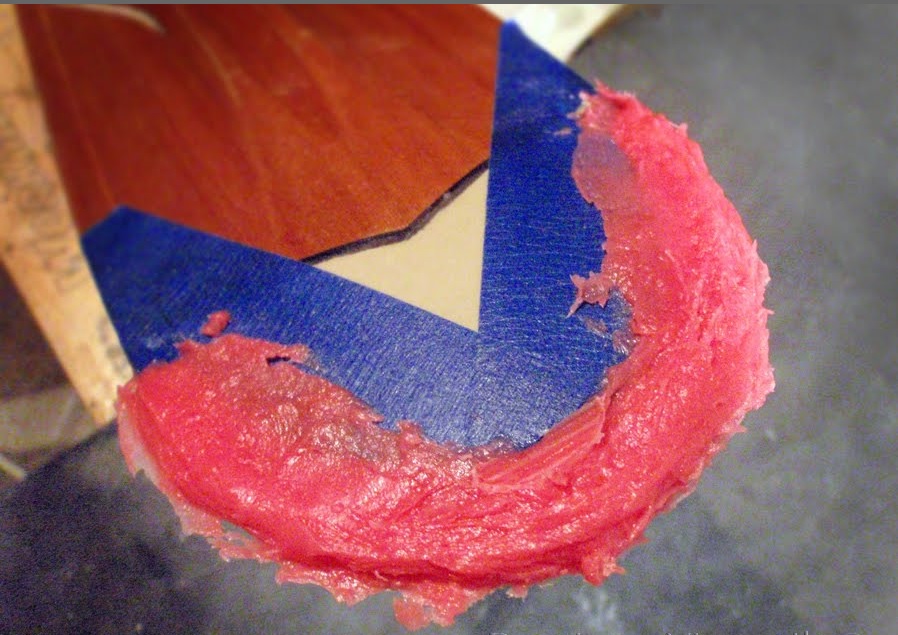

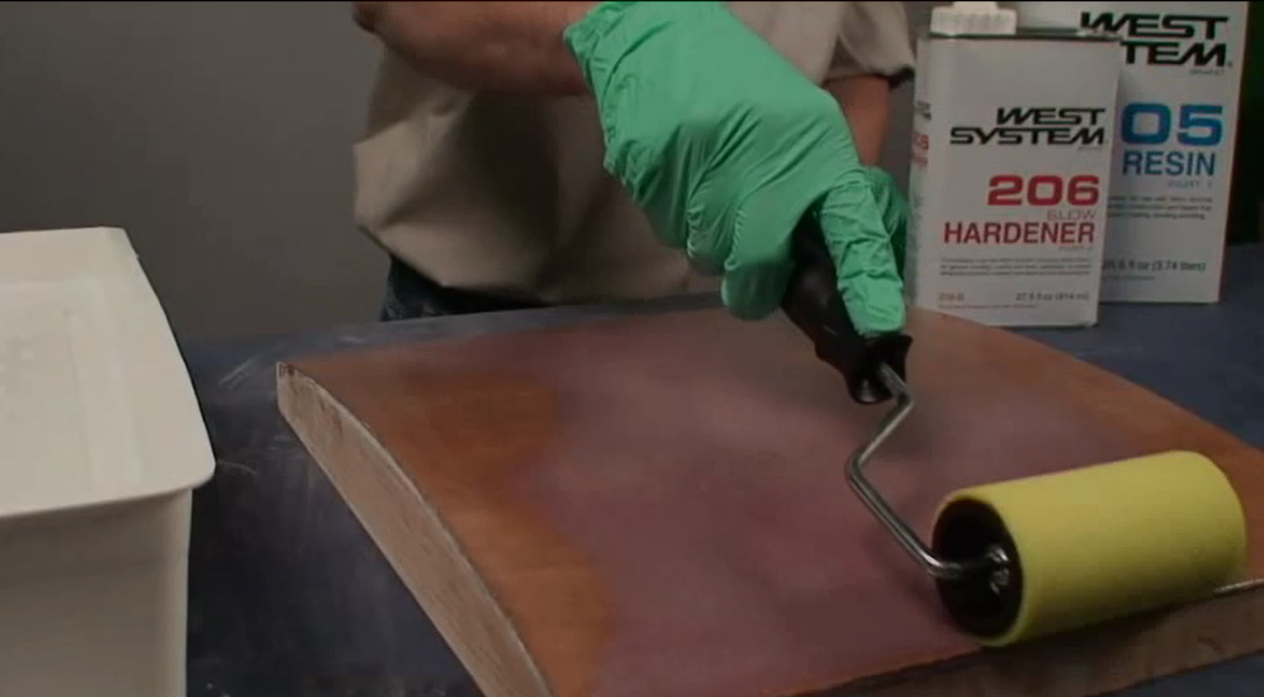

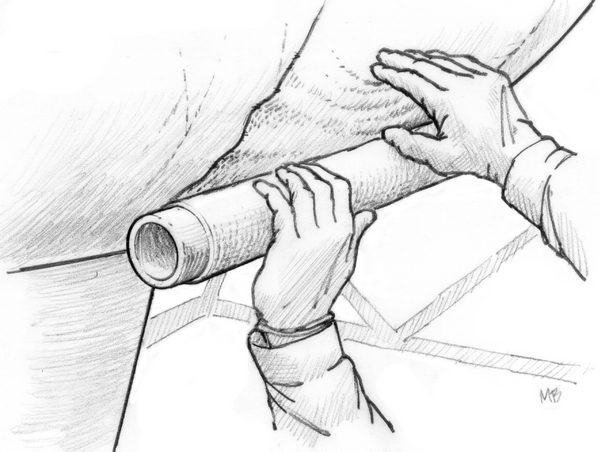

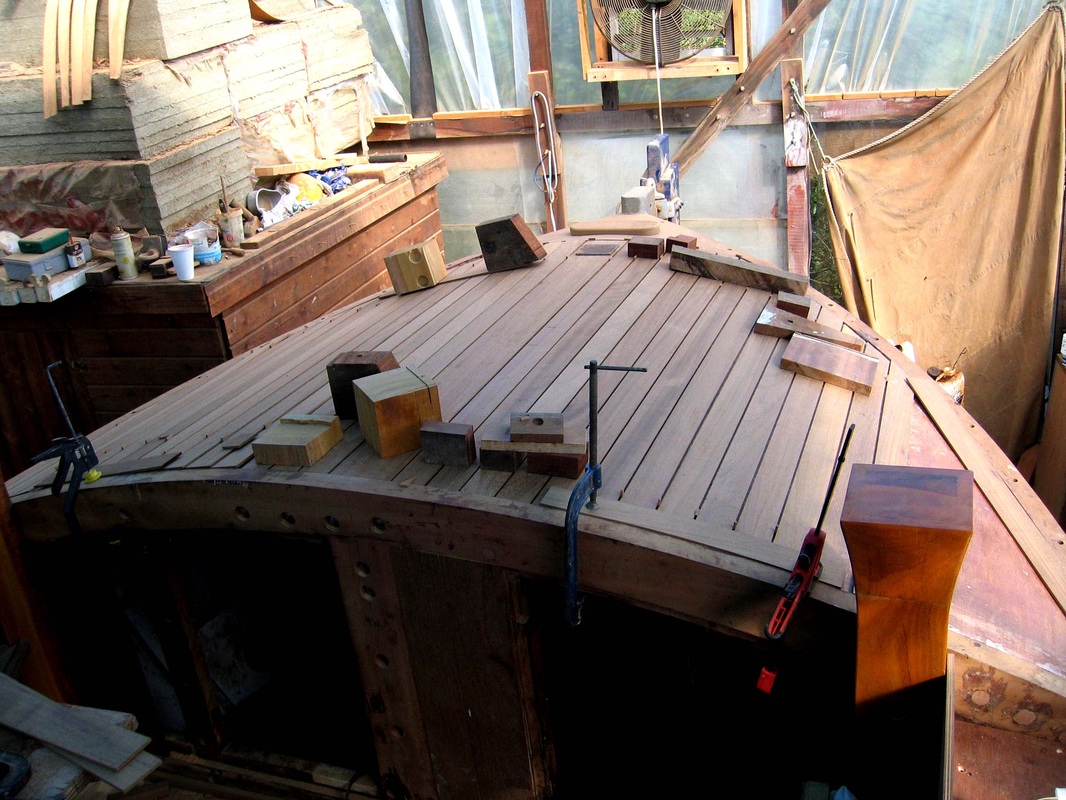

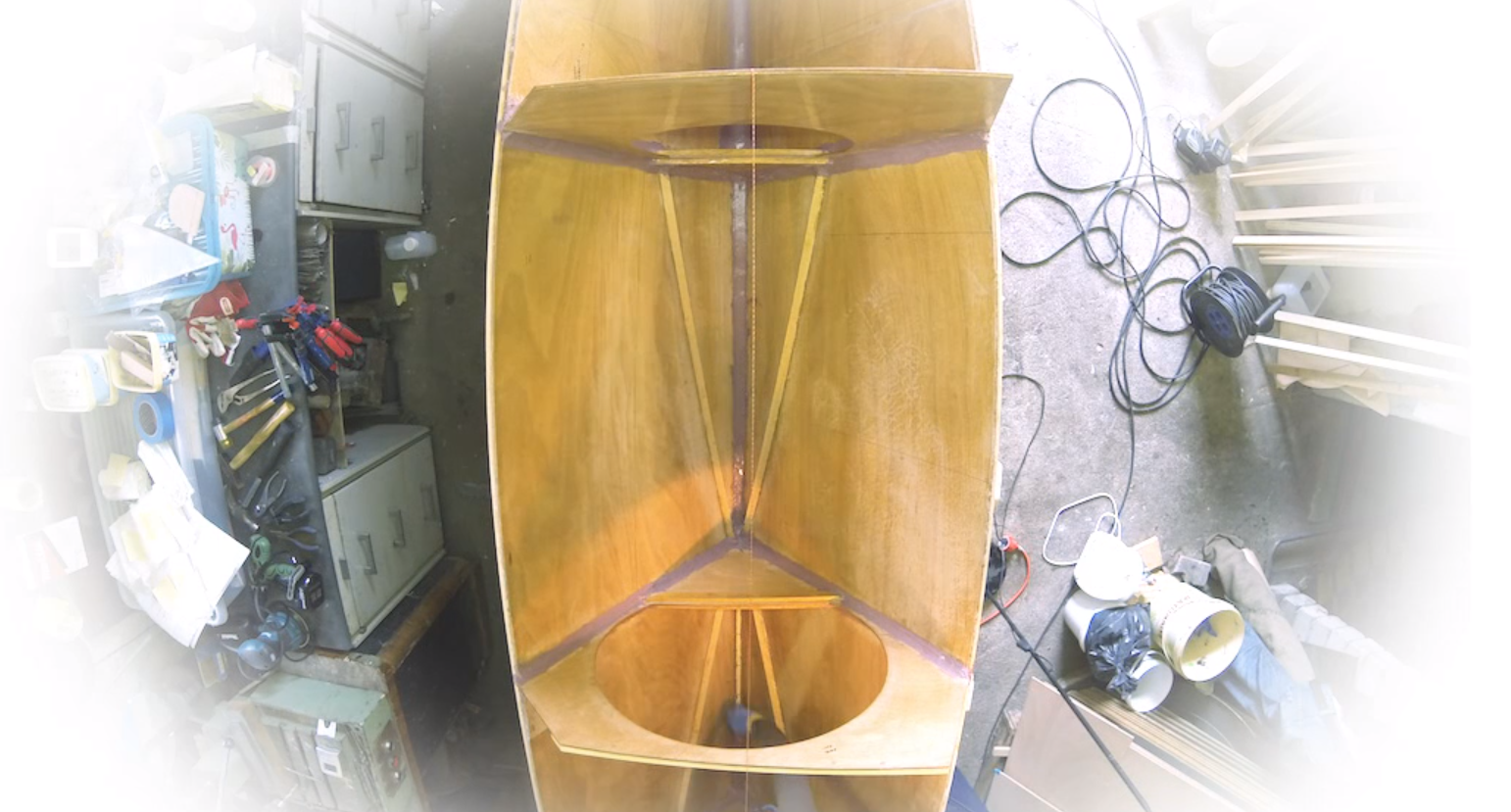

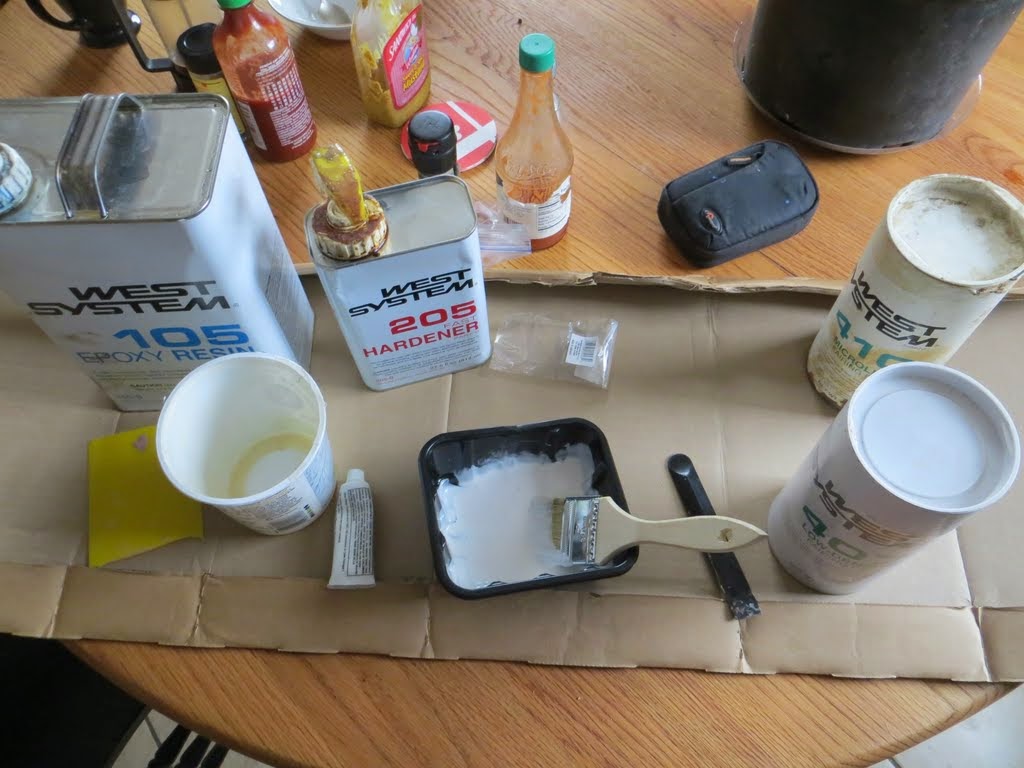

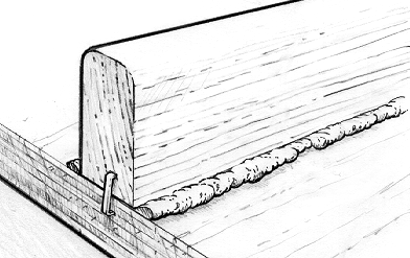

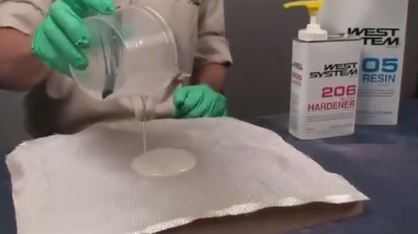

Given a holiday week with poor weather and changed circumstances I once more took up the tools and materials that I love so much. In an effort to keep at bay the maintenance and DIY tasks on our 110 year old cottage. The summer house in the corner of our garden needed a new roof ... DIY Garden Roof – Quick Epoxy Fix? More