Reparing Gelcoat Blisters on a Fibreglass Boat Using Six10 Epoxy?

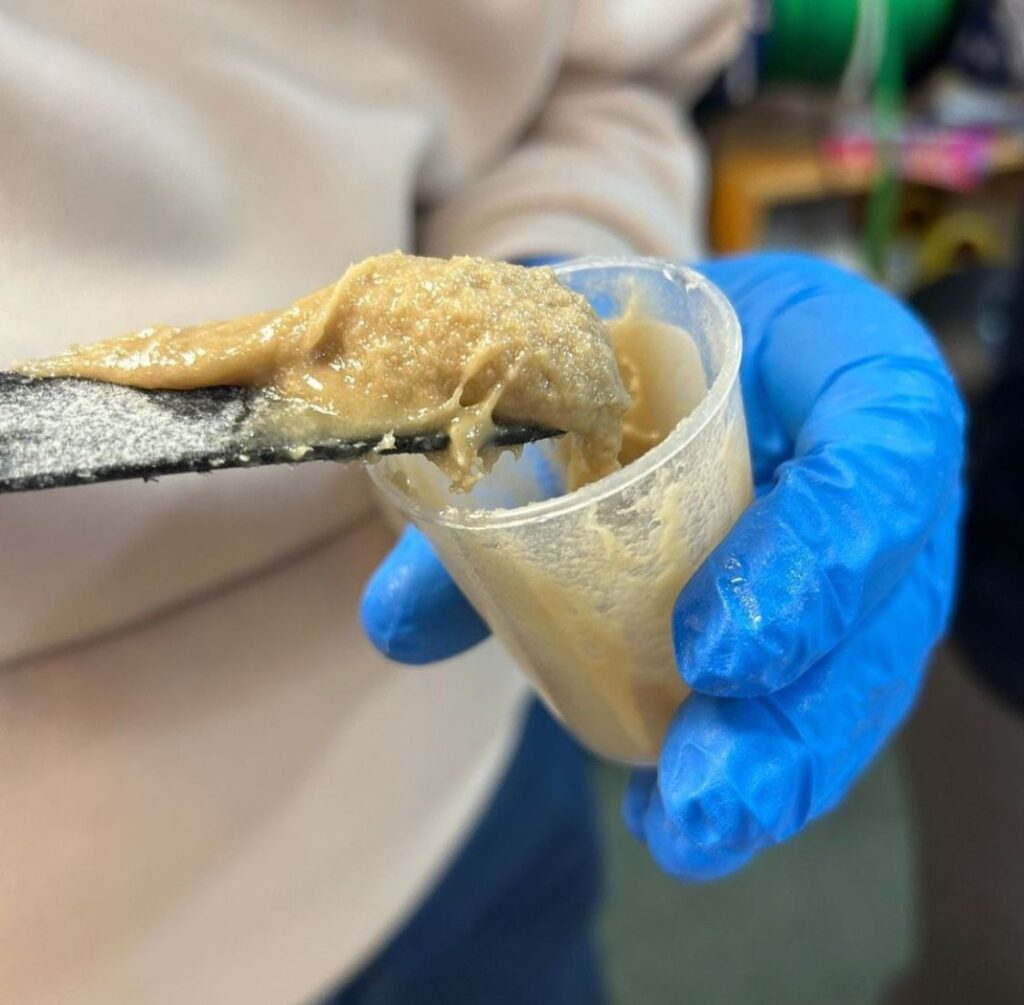

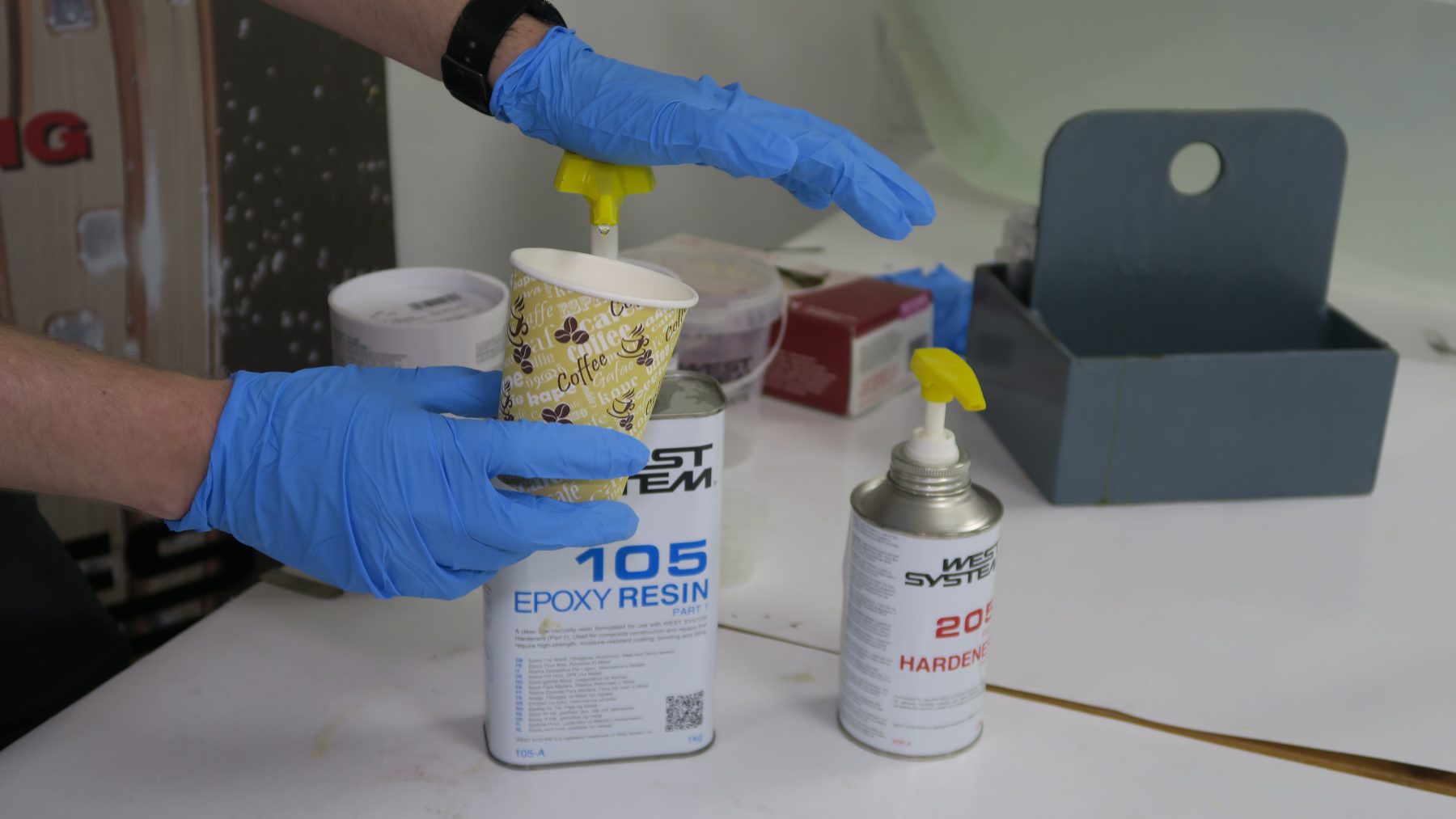

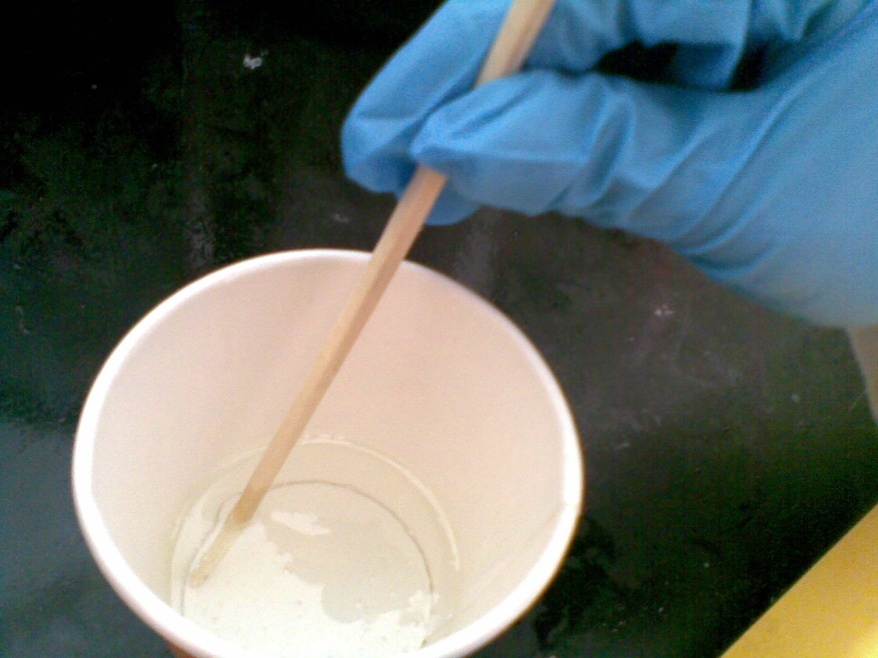

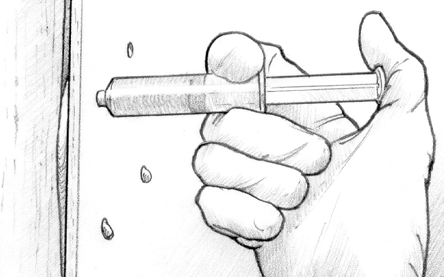

Noticed Blisters in Your Gelcoat? What’s Next? You’ve just pulled your boat out of the water. There, you see it – blisters in your gelcoat. Ignoring them might seem like the easy way out, but it’s not. Neglect could lead to bigger problems like a complete hull overhaul, gelcoat removal, or even a full barrier ... Reparing Gelcoat Blisters on a Fibreglass Boat Using Six10 Epoxy? More