How To: Five reasons why two-step bonding with marine epoxy creates a better joint

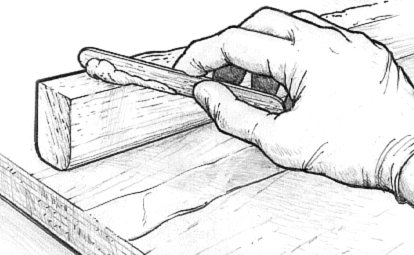

Hamish Cook, Technical Adviser at West System International, explains why two-step bonding should be your first choice for structural strength. Two-step bonding is a straightforward process. You wet out the surfaces you want to join using a mix of resin and hardener – that’s step one. Then you add filler to the mix and use this thickened marine epoxy to coat one of the primed surfaces, carefully clamping it to the other surface while it’s still tacky to create your joint – that’s step two. Using this process – rather than the single-step method of simply using a thickened epoxy mix without wetting out the surfaces first – creates a superbly strong, resilient and long-lasting joint. Here’s why:

Two-step bonding creates a ‘3D’ bond

Because the resin-hardener mix is less viscous than the thickened mix, it really soaks into porous surfaces, penetrating deep into the fibres of the materials you’re bonding. You can think of it as 3D bonding – rather than 2D. And even if you’re using less porous materials, like metal, that first step still does a very effective job of preparing your surfaces for a powerful bond.

Two-step bonding avoids resin-starved joints

If you add certain fillers – especially more fibrous ones – to an epoxy mix and then leave it for a while, you’ll notice that a pool of resin starts to gather around the mix. For me, that’s actually a pretty compelling argument for two-step bonding. Resin can separate from a mix and, if you’re too heavy-handed, it is possible to squeeze it out of a joint completely if you use a thickened mix without priming the surfaces first. The two-step process gets rid of this risk by ensuring the fibres are saturated with resin before you create your joint.

Two-step bonding creates a primary bond

The two-step process creates a chemical (primary) bond rather than a mechanical (secondary) one. In other words, the epoxy you apply to the partially cured epoxy creates a single, fused layer – and that’s a big part of the reason the resulting joint is so effective.

Two-step bonding is quicker

While there are, obviously, two steps to two-step bonding, it’s a single, continuous procedure. You wet out the surfaces. You add a thickened mix. And once you’ve clamped and cleaned or filleted, you’re done. If you choose instead to prime the surfaces and then create the joint later on, you need to wash and abrade the surfaces between these two steps. That’s a longer process and requires more effort.

Two-step bonding ensures you’re totally focused

This last point is a personal perspective, but I’ve always felt that using two-step bonding creates a better result because it totally focuses your attention on your work. It makes you think about priming and about applying your filled mix while the surfaces are still tacky. You can’t forget about it and put the kettle on halfway through, and in my experience that level of focus does generate a better and more satisfying result.

WEST SYSTEM® 205 Fast Hardener® or 206 Slow Hardener® and WEST SYSTEM 105 Epoxy Resin® are ideal products for effective two-step bonding. To find your nearest stockist click here .