Trade Secrets: Reparing Gelcoat Blisters on a Fibreglass Boat Using Six10 Epoxy?

Noticed Blisters in Your Gelcoat? What’s Next?

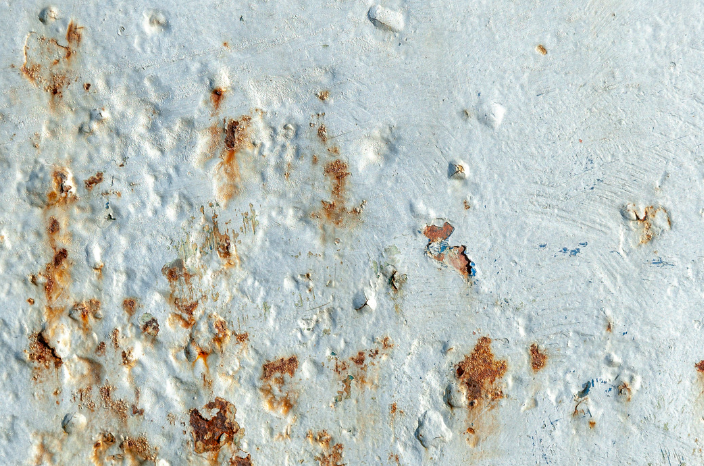

You’ve just pulled your boat out of the water. There, you see it – blisters in your gelcoat. Ignoring them might seem like the easy way out, but it’s not. Neglect could lead to bigger problems like a complete hull overhaul, gelcoat removal, or even a full barrier coat job. So, what’s the solution? Address the blisters as they appear. Perform a quick repair with WEST SYSTEM® Six10® Thickened Epoxy Adhesive. It’s easier than you think!

How Do You Open the Blisters?

Start by opening the blisters. Use a small abrasive tool for this. Make sure you remove the entire blister, including the edges of the blister dome.

Next, fill the cavities. Use the mixing wand provided with the adhesive. Then clean the cavity. Use an alcohol prep pad and change it frequently to remove any contaminants. Repeat the process until the laminate is dry to the touch.

How to Apply Six10 Adhesive?

Now, fill the cavities using the Six10 adhesive. Dispense it through the static mixing wand. Spread it flush with the surrounding hull using a putty knife or plastic spreader. Remember, don’t overfill!

After filling, it’s time to wet sand. Use 80 – 120 grit sandpaper or wash with water. If it’s cool, let the epoxy cure overnight before sanding.

Finally, apply your chosen paint.

What Makes Six10 Thickened Epoxy Adhesive Effective?

Six10 Adhesive is a fumed silica-thickened epoxy. It’s an excellent moisture barrier. When dispensed into the blister cavity using the static mixer, it fills the void with air-free epoxy. This prevents small bubbles in coatings from creating shortcuts for moisture to permeate into the hull structure. The result? A moisture barrier better than the original gelcoat!

How Long Does this Repair Method Last?

Blisters develop slowly. With this method and careful monitoring, your hull should stay in good shape for two to three years. But remember, if blisters become too extensive, a complete overhaul might be necessary. This repair method is intended for localized blisters or temporary repairs prior to a complete anti-osmosis treatment.

Have you subscribed to our FREE monthly newsletter? Sign up here!

Working on a project? Share it with us! Click here…