How To: The perfect seal: installing hardware safely and securely with WEST SYSTEM epoxy

When installing hardware it’s essential that you plan the process meticulously to avoid any safety issues or on-board damage along the way. This Trade Secret shares two methods to keep your hardware secure and watertight using WEST SYSTEM epoxy.

At one time, installing hardware may have been seen as a process best left to the experts. Many that braved the process themselves would often be left with leaking decks or even damage to the boat core.

The main problems with installing hardware occur when fasteners are not bedded correctly or, in some cases, boat owners leave holes unfilled entirely, allowing water to seep on board.

However, thanks to the exceptional water resistance of WEST SYSTEM epoxy, hardware can now be installed at home with lasting results.

There are two ways to approach the installation. The first is to bond all fasteners (screws, bolts or threaded rod) directly to the surrounding wood fibre. The second is to bond both the fasteners and the hardware itself to the immediate wood fibre on which it rests. Using these hardware bonding installation techniques, you’ll dramatically improve the load-carrying capacity of your hardware so that you can continue to modify your boat with confidence.

The fastener-to-wood bond can be done in several ways. The easiest and most common method is to simply wet out a standard-size pilot hole for a given fastener with resin/hardener.

Make easy fastener bonds as follows:

- Firstly, use a pipe cleaner or syringe to work the mixed epoxy well into the hole.

- Secondly, insert the fastener in the hole and allow the epoxy to cure. This forms a wood/epoxy matrix around the fastener that is much stronger than the wood by itself and distributes the fastener load over more of the wood fibre area.

This technique takes advantage of the fact that WEST SYSTEM® epoxy has a much higher density and strength than the wood fibre itself by bonding the hardware base directly to the surface. Bond for increased load transfer as follows:

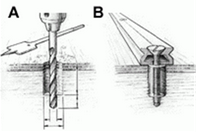

- Drill the fastener holes

Drill an oversized pilot hole to increase the amount of exposed wood area that the epoxy around the fastener will bond to. This may be twice the diameter of the fastener. Drill the hole 2/3 the depth of the fastener. Next drill a normal sized hole the remaining third, to allow for the bottom threads of the fastener to bite into the wood fibre to remain in position as the epoxy cures.

- Prepare the hardware

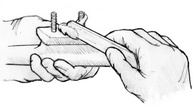

Wash the contact surface of the base with a pure solvent, such as WEST SYSTEM 850 Cleaning Solvent, to remove any contamination. Allow the solvent to completely evaporate. Abrade the contact surface with a wire brush or 50-grit sandpaper – this provides a “key” on the surface for the epoxy to adhere. - Coat the bottom of the hardware with un-thickened epoxy

Wire brush or sand the wet epoxy into the surface with 50-grit sandpaper. - Fill the holes

Fill the holes to the top with epoxy. Allow the epoxy to soak into the exposed end grain of the wood for a few minutes. Then inject a non-sagging 406 epoxy mixture into the hole. Use enough mixture so there are no voids in the hole after inserting the fastener.

- Bond the hardware

Coat the bottom of the hardware and the fastener threads with the thickened mixture and then place the hardware in position. Then, insert and tighten the fasteners until a small amount of the mixture squeezes out of the joint. Make sure you clean any excess epoxy mixture that has squeezed out. Allow the epoxy to cure at least 24 hours before applying load to the hardware.

Whichever method you choose, make use of our support pages on the WSI website to get more expert advice on your installations.