How Can You Repair a Hole in a Fibreglass Boat?

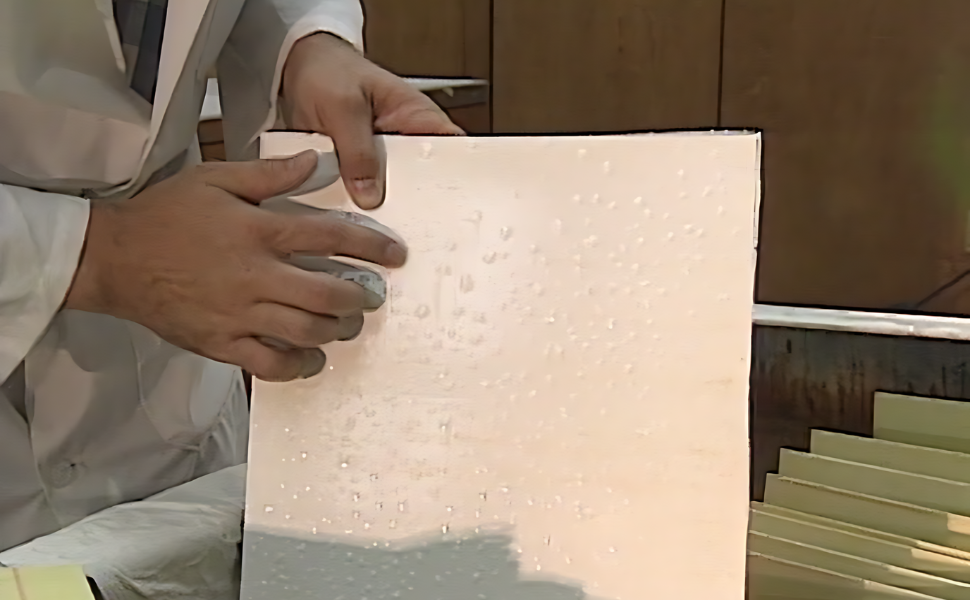

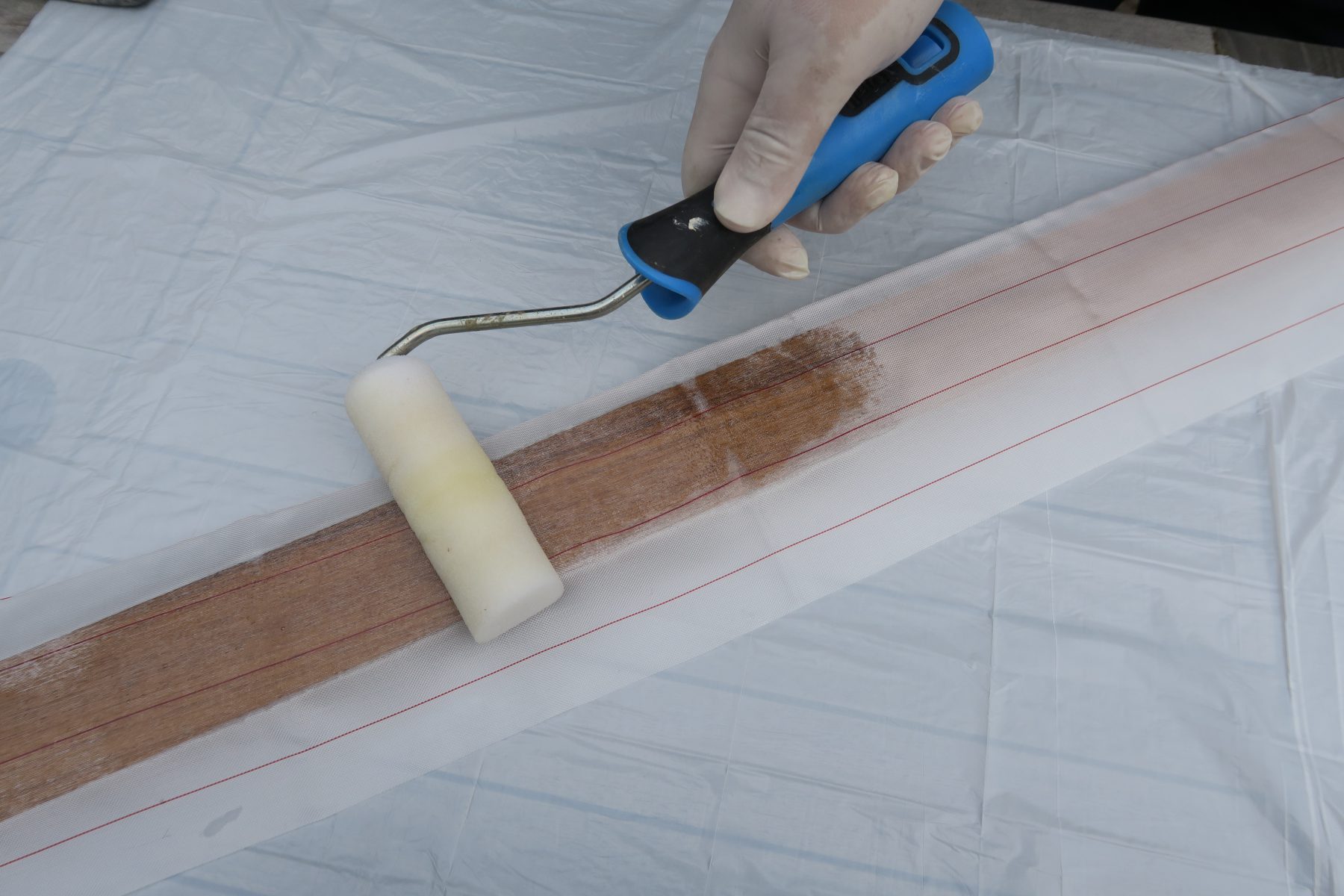

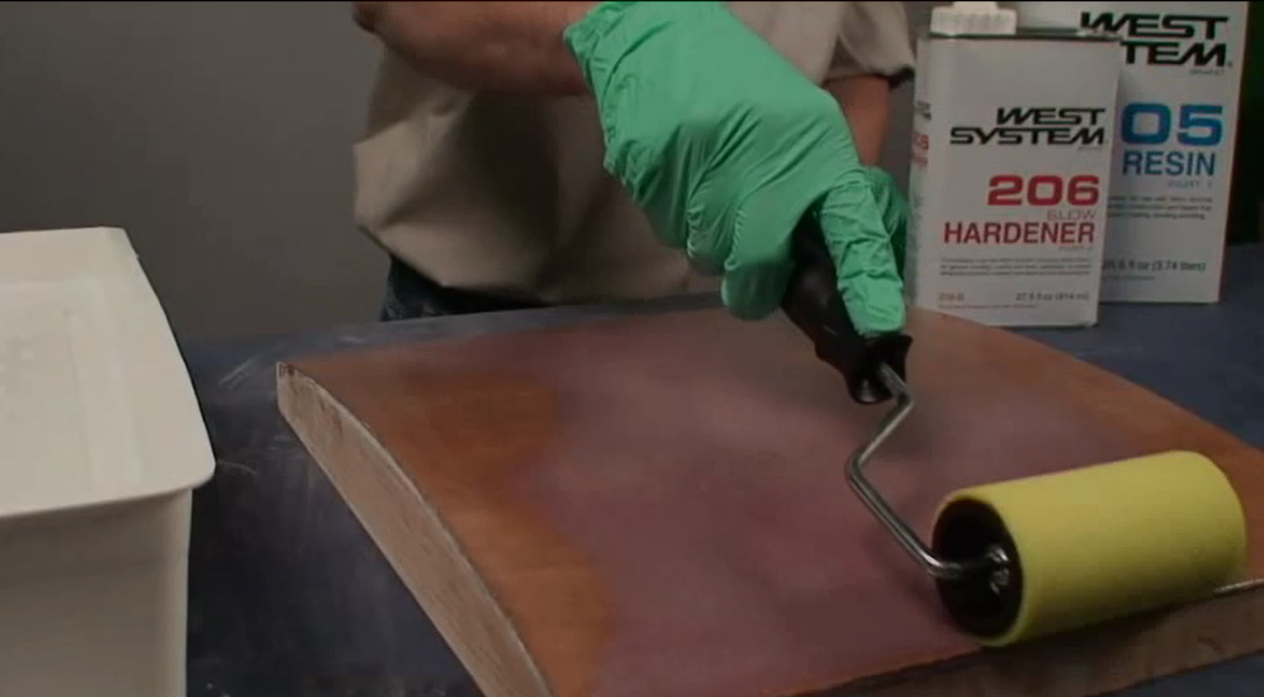

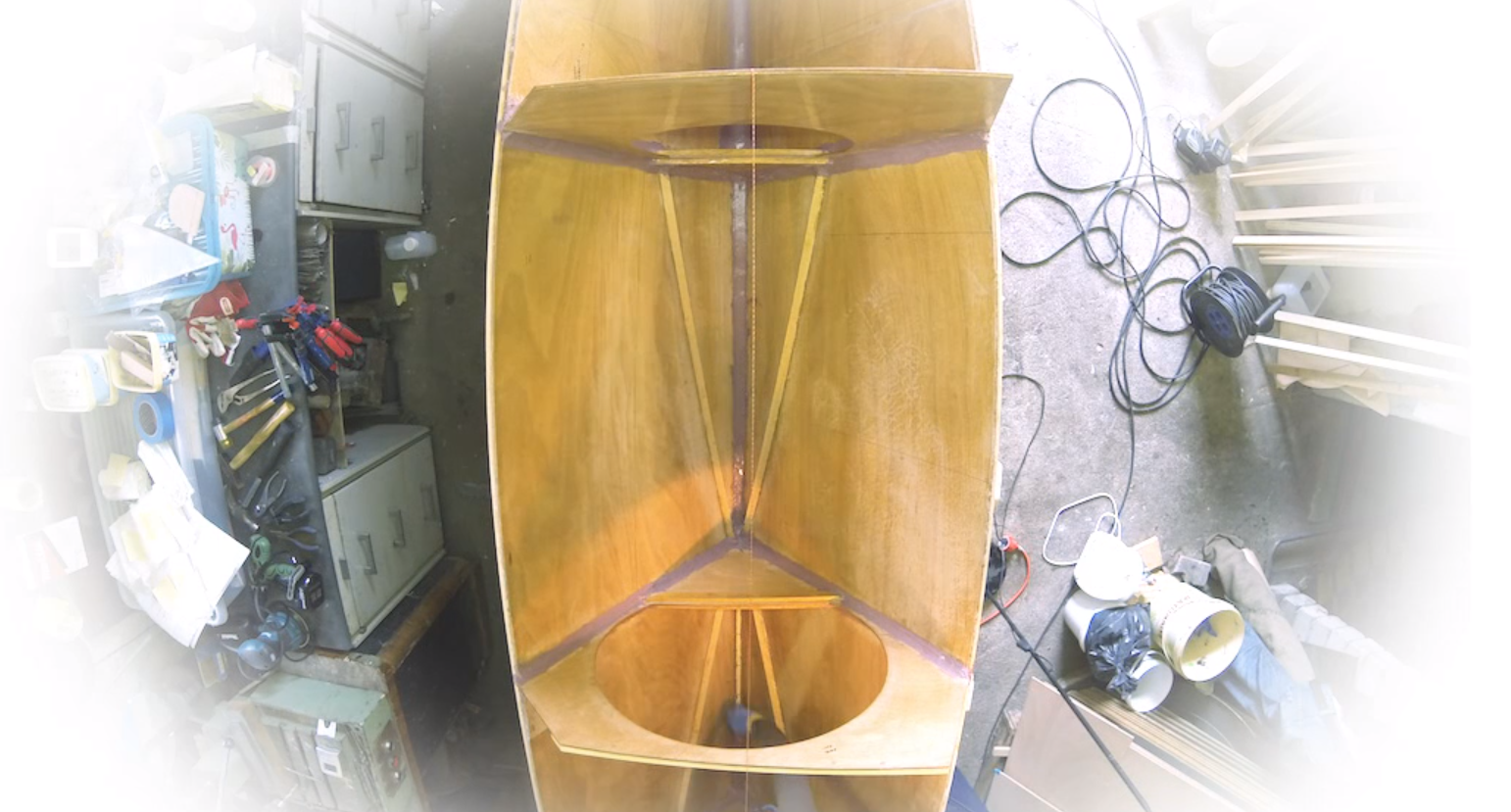

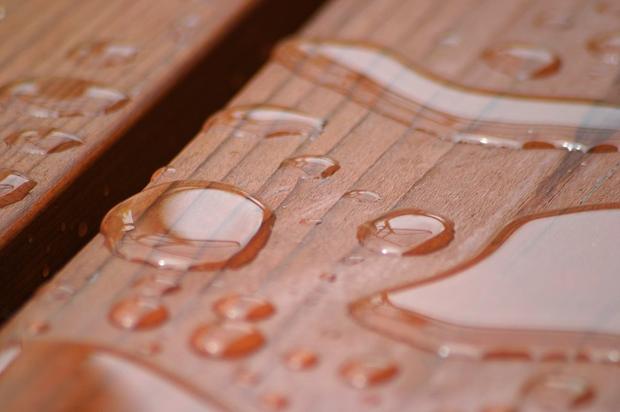

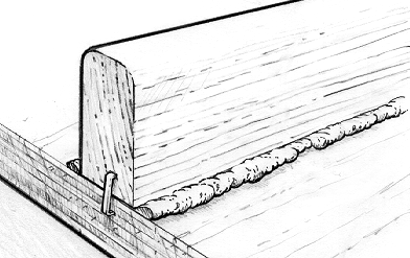

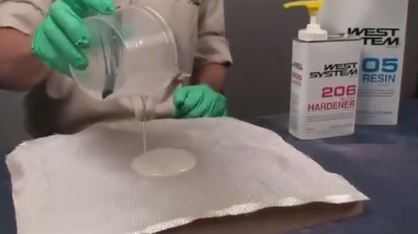

Don’t panic! A hole in a fibreglass boat is a common issue that many boat owners face. Thankfully, it’s not only easy to fix, but the repair process can also be a great opportunity to learn more about your boat’s construction and maintenance. How do you assess the damage? The first step in any repair ... How Can You Repair a Hole in a Fibreglass Boat? More