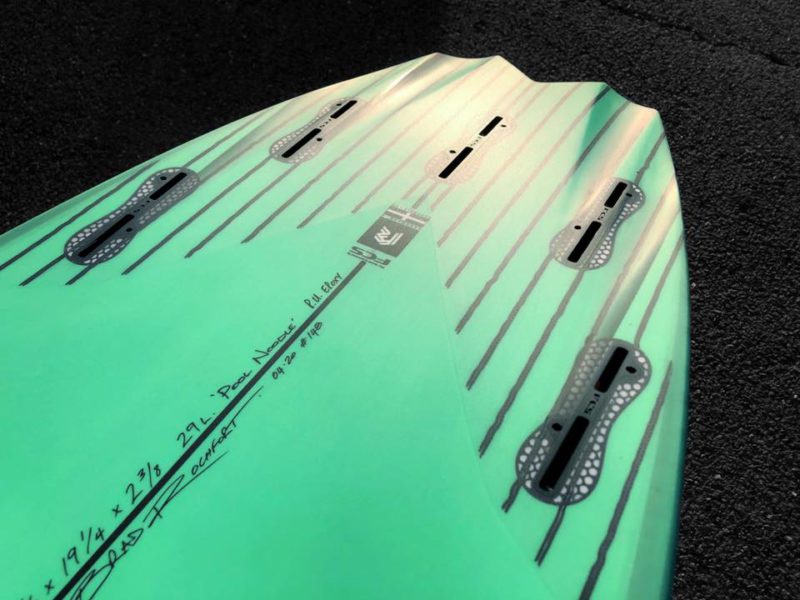

Projects: How Does Rochfort Customs Create Boards Using Entropy Resins®?

Brad Rochfort is a garage shaper who takes the ultimate care with his boards. “People must be happy if they have to wait for a board.” The fact that people are willing to wait for months attests to the quality of his product.

Created lovingly in Newquay, Cornwall using the finest bio-based Entropy Resins® with Super Sap® technology, Brad admits he can be quite fussy about quality.

How is the Balance Between Hobby and Career Maintained?

“I make sure I have time to focus on each board – to give that extra attention to detail.“

“I’m quite particular and won’t let anyone rush me, so I limit my production to two boards per month, no more. As the orders keep coming in, the queue just lengthens, and you must be ready to wait.”

He’s been shaping boards for 15 years, and this is his hobby. His career is working for Surf Hardware Intl. (the company that manufactures FCS fins) as UK Territory Manager.

But his heart belongs in his garage, and the art he makes for surfers around the country.

“I do every little process, from shaping to laminating, artwork and tints, sanding and finishing,” Brad says. “The shape, the details and every measurement has to be exactly right for each individual customer, both visually and in performance.”

“If people rush sanding it’ll show in the finished product for the life of the board. It’s the little things that make the difference.”

One of the larger things that make a difference is choice of epoxy.

He says that the “advantage for me using Entropy Resins products 100% of the time is that I can use it on all types of foam”. (Brad mainly uses polyurethane foam).

It could be argued that his penchant for epoxy was somewhat forced upon him.

“I do a lot of surfboard repairs,” Brad says. “There are more and more epoxy boards in the marketplace so my work evolved to cater for epoxy repairs.”

How Did the Introduction to Entropy Resins Occur?

He was introduced to Entropy Resins by Luke Young, a fellow shaper and after researching a variety of different epoxies, chose to follow Luke’s advice. “I did experiment with another brand, but have stuck with Entropy Resins products ever since.

“Entropy Resins products are working great for me,” he says. “I like the eco-credentials involved with it and the fact it’s solvent free and also free of VOC’s (volatile organic compounds). This is beneficial in an enclosed garage space.

“I really like the flexural strength epoxy gives compared to polyester resin, as it has higher impact resistance, increased fatigue strength and is less brittle. It flexes in a positive way which can be used to the benefit of the surfboard’s performance. Entropy Resins products give me all these benefits. Plus, it looks amazing.”

What Epoxy In Particular?

Brad uses Clear Laminating Epoxy (CLR) on boards with his existing tint and pigment colours, some of which he’s had for ten years or more. He can’t wait to try the new colour tints from Entropy Resins as soon as he uses up his current ones. “CLR excels at preserving the tint’s true colour.” He has also successfully used the same resins for other creations, such as resin river tables and resin jewellery, which he makes from the leftover resin from board construction.”

He uses Entropy Resins Optically Brightened Laminating Epoxy (BRT) for pure white boards with its UV stabiliser. “Some UV stabilisers just don’t look good but this makes boards hit the right note, and keeps them white for longer.”

With his custom-made board’s starting at a mere £450, and given that each one takes a minimum of 10 hours, no one can disagree with Brad’s final words:

“Shapers are the most underpaid artists in the world. They handcraft totally unique, functional pieces of art.”

Find out more about his designs and how he makes jewellery with his resin and fibreglass ‘offcuts’ on his website (https://www.rochfortcustoms.co.uk).

Have you subscribed to our FREE monthly newsletter? Sign up here!

Working on a project? Share it with us! Click here…