Trade Secrets: TRADE SECRET: Filling a horizontal hole with epoxy

This month’s Trade Secret investigates how to avoid leakages when filling a hole with epoxy on a vertical surface. These techniques will help you use your epoxy effectively, keep surfaces clean and avoid waste.

Thanks to the laws of gravity, filling a vertical hole is a relatively simple task. However, things become more difficult when you need to fill a horizontal hole in a surface such as a wall or fence.

Without the right techniques epoxy can start to seep out of the hole or, in the worst case scenario, completely drain out. Here are the top three techniques we recommend for filling a horizontal hole:

- Tape over the hole after you’ve filled it

Use masking tape to cover the hole as soon as it is filled. This will prevent epoxy draining out before it cures. - Inject epoxy through the tape

Cover the hole with masking tape before you inject the epoxy. Puncture a hole in the tape big enough for a syringe and inject through the tape into the hole.

- Thicken the epoxy

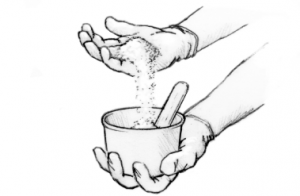

Thicken the mixture so that it remains in position without the need for tape. This method will work best for larger holes that you can fill using a mixing stick, as this consistency will no longer be suitable for a syringe.

If you have any questions about epoxy techniques and applications, get in touch with an expert.

Image credit:https://bit.ly/1LDqxx6