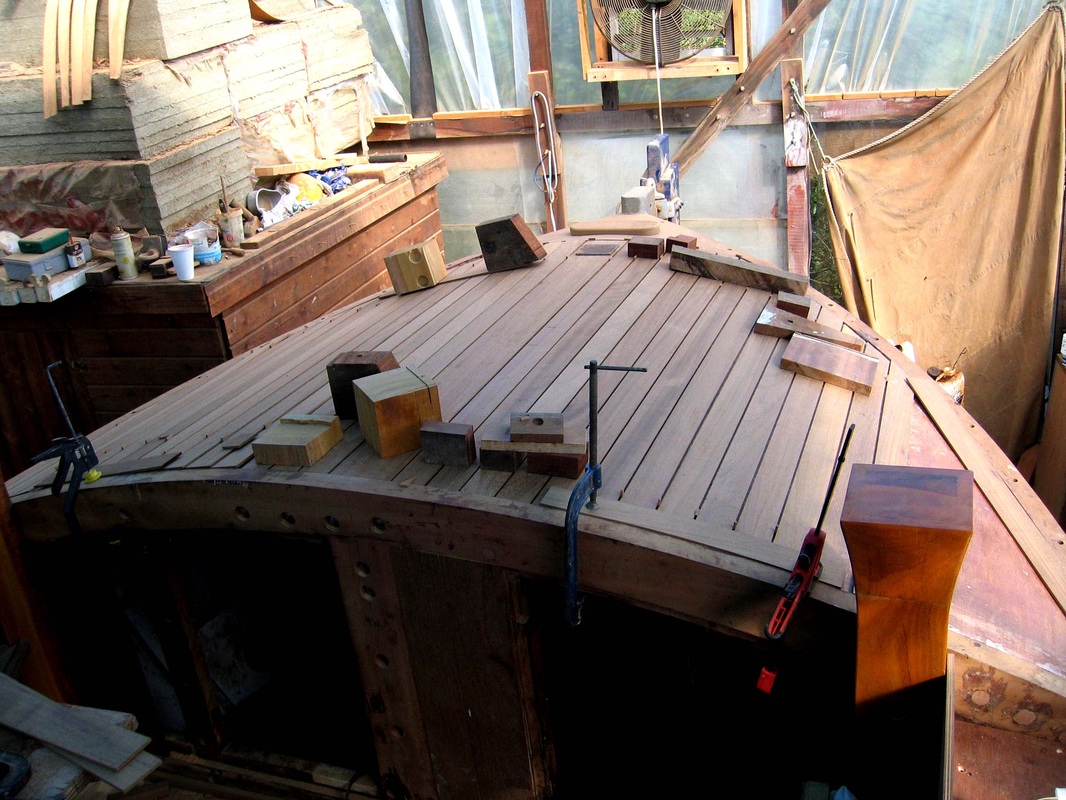

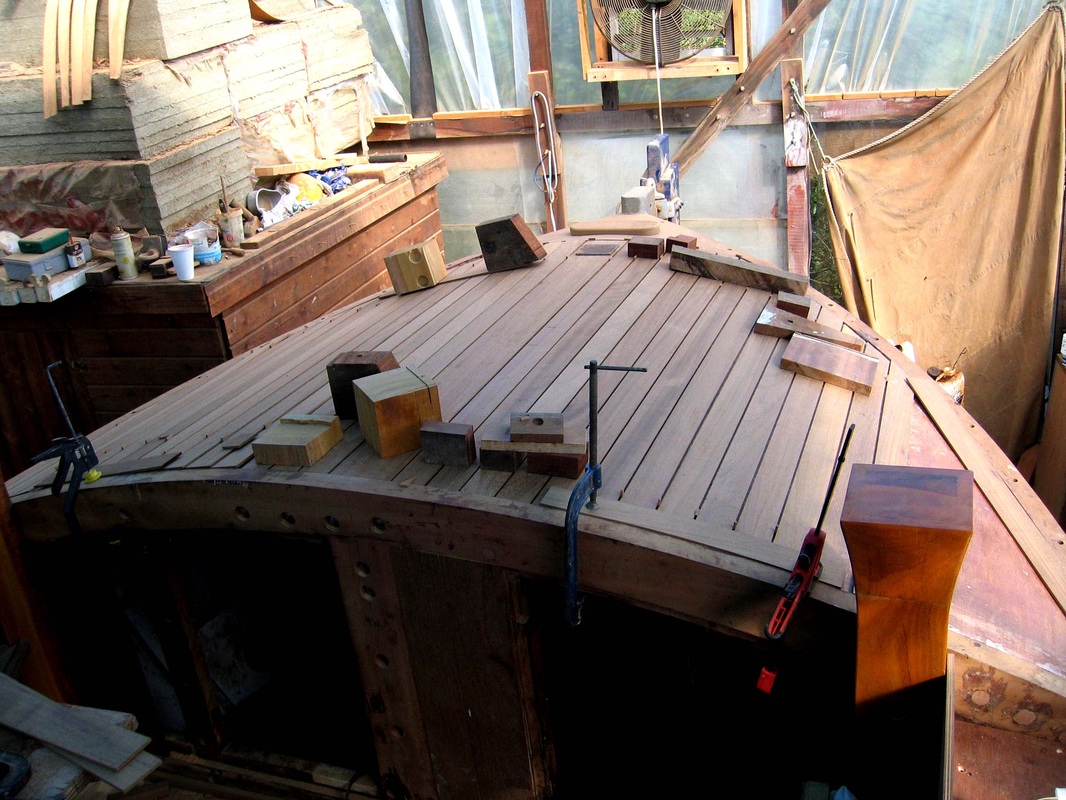

There are fewer things more beautiful than a teak deck with sharp black seams. Every classic boat has them – like Mark Raynes’ MANCHESTER AND SALFORD lifeboat. Here, he talks us through the restoration of his stern deck, step by step. Traditionally, a teak deck was made from one- to two-inch thick planks and the ... Restoring a laminated teak deck with epoxy/graphite seams More

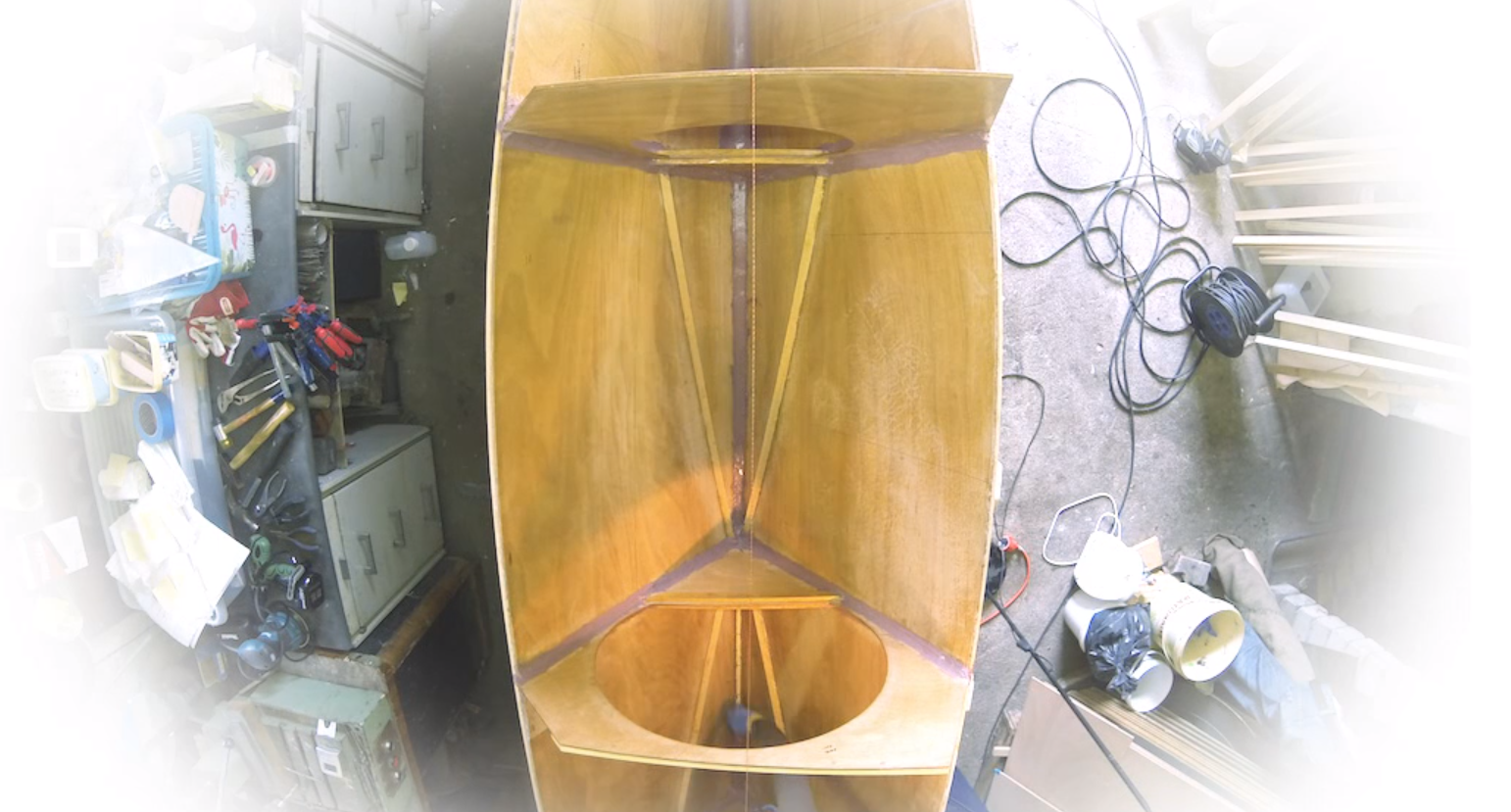

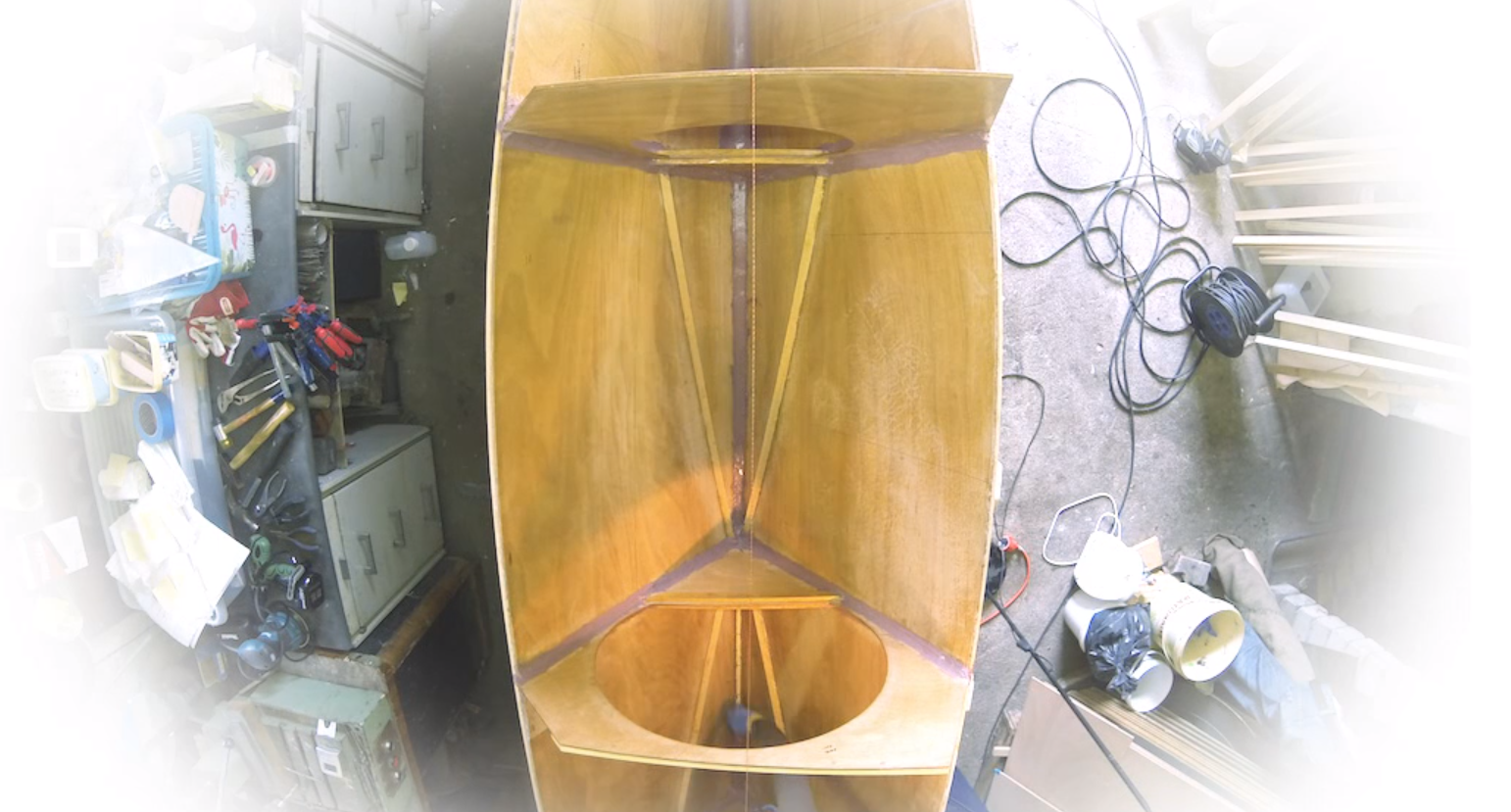

Work doesn’t necessarily slow down after retirement, as engineer Martin Ellison proved when he left his teaching post at the age of 59 and set about building his first boat. What started as some prompting from his wife to find a meaningful project evolved into the idea of building a 40ft catamaran. Martin tells epoxycraft ... Constructing a 40ft catamaran with WEST SYSTEM epoxy More

Bear Mountain Boats is a distinguished name in Canadian canoe-manufacture. In this profile of WEST SYSTEM® epoxy suppliers, co-owner Joan Barrett tells us how a little cedar canoe sparked a business venture that changed canoe building in Canada forever. Bear Mountain Boats came to life in the early 1970s, when my partner Ted Moores, searching ... All about: Bear Mountain Boats More

When Sweden-based carpenter Paul Allsop first laid eyes on a cedar strip boat in Hawaii, it captured his imagination and he knew he had to build one of his own. It took him a further seven years to start but once he did, he couldn’t stop. Paul gives us an insight into his passion project. ... Building a wooden boat that shines in the sun More

In the early 20th century, there were more than 60 watermills on the river Drava in Croatia. Destroyed in World War II, none were rebuilt – that is, until now. We find out what role epoxy has to play in bringing this impressive craft back to life. “It should be an awesome place to take ... Renewing a tradition: building a watermill with epoxy More

At 25 metres long and built of Slavonian oak and pine, the brand new Aurora Colapis – “Ship of the Corn” – is a striking sight. This reconstruction of a 19th century grain boat is set to bring an ancient Croatian trade path back to life and epoxy has a big role to play. “Up ... The Ship of the Corn: reviving an ancient Croatian trade path More

Captain Glenn James of the Bounty Hunter guides you through his detailed instructions on how to expertly sheath a wooden boat with WEST SYSTEM® epoxy. In doing so he added many years to Bounty Hunter’s life, reduced ongoing maintenance time and boosted performance – the dryer and lighter hull increased her top speed from 15 ... How sheathing with WEST SYSTEM epoxy can reduce maintenance time and increase performance More

Sailing legend and pioneer of marine epoxy Meade Gougeon recounts the uplifting tale of how Adagio was re-commissioned after five years in retirement. Adagio was the first large wooden boat entirely bonded together with epoxy using no permanent fastenings, which might be commonplace now but was revolutionary stuff in the 1970s. Find out how Adagio ... The story of a revolutionary wooden epoxy boat More

We wanted to share the passionate story of father-son team Dave and Scott Wrzesinski and their Marine Services Unlimited boatbuilding shop. From their small shop in Lake Houghton, Michigan, USA, Dave and Scott rebuild classic boats, both wooden and fibreglass, including a 1957 Chris Craft 21ft Continental – one of only six ever produced. They ... In love with their craft: how epoxy helps this classic boat builder More

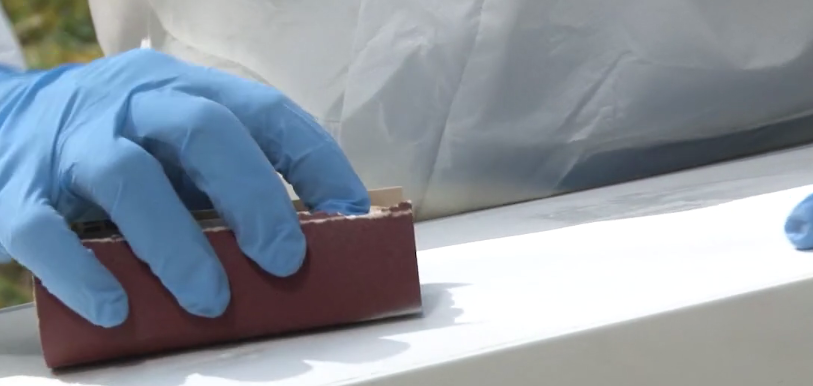

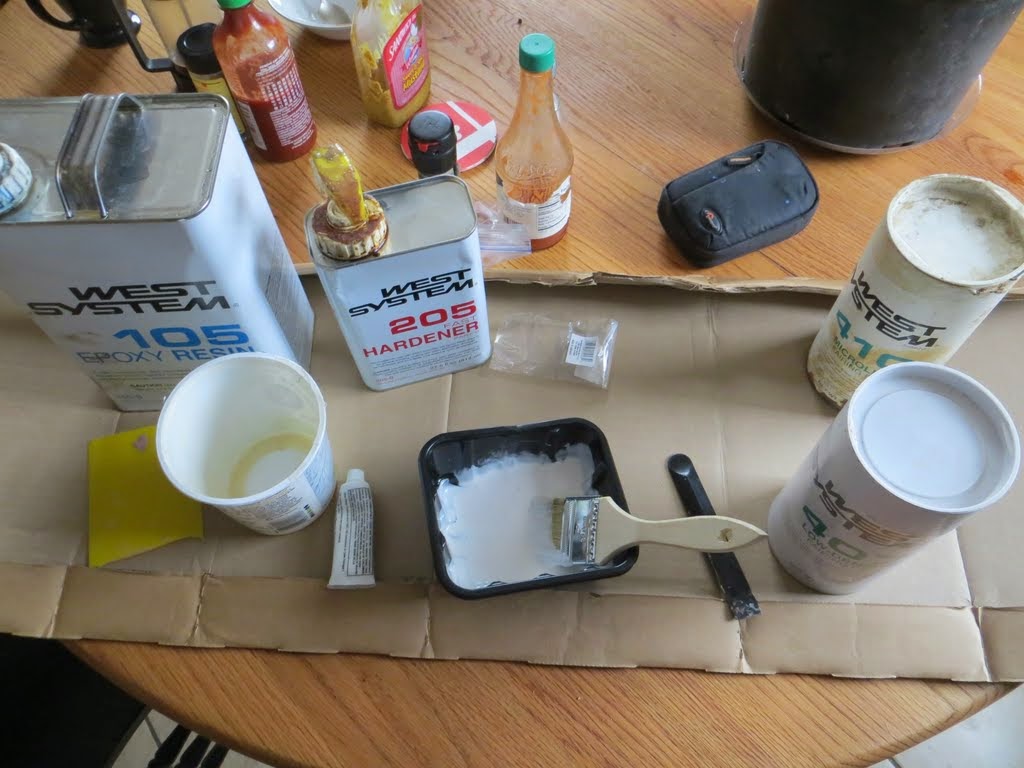

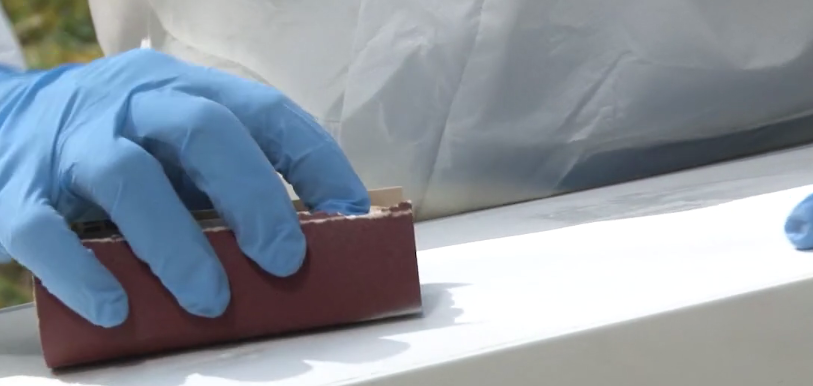

When it comes to preparing a surface for epoxy application, the cleaner you make the area the better the outcome will be – any sort of contamination on the surface will likely result in reducing the adhesive power of epoxy. Surface roughening improves the strength of the adhesive bond by enabling the epoxy to mechanically ... Ensuring clean surfaces makes for a strong epoxy bond More

What do you do when you find blisters in the gelcoat of your boat? Leave them and hope they may disappear? If you do that, you could be creating a bigger fibreglass boat repair job for yourself in the future. Blisters in your fibreglass boat don’t have to be the end of the world but ... Fibreglass boat repair: six steps to fixing gelcoat blisters with Six10 epoxy More

Steve Bennett started building rockets when he was just 12 years old. Today he’s the CEO of Starchaser Industries, which designs, builds and launches the UK’s biggest rockets – and WEST SYSTEM® epoxy plays a critical role. The first rockets that Steve Bennett built were probably no more than 20cm tall. “I had mixed results; ... Epoxy: helping the UK reach for the stars More

When Dan Mill first came to Galway, Ireland, from New Zealand on a six month visa, he couldn’t have imagined what was in store for him. Before he knew it, Dan was working on one of the biggest boatbuilding projects of his life: building Nimmo, the 68ft cruiser. Four years and plenty of epoxy later, ... An unexpected journey: landing the project of a life-time More

There’s nothing more satisfying than applying that final finish coat after a long project. At the same time, there’s nothing more frustrating than waiting week after week for all those layers of varnish to dry. “Varnishing is often a time-laboured process…But there is a way to achieve the perfect varnish, in less than half the ... How to effectively varnish – in under a week More

West System International Technical guru David Johnson explains how to fix a rudder that’s taking in water. If there’s a top ten list of questions from boat owners who want to carry out their own repairs, “how do I fix the rudder?” is almost certainly up there. Especially if the boat is 20 years old ... How to use epoxy to fix the rudder of a sailing yacht More

We found this fantastic resource from Mark Ryan on how to repair a mast truss, complete with helpful photos to guide you through the process. It needn’t be a complicated task – it just takes some patience and the experience of someone who’s been there before. Mark recommends using WEST SYSTEM 105 Epoxy Resin® with ... How to repair the mast truss on your fibreglass boat More

Celebrating sixty years since he first journeyed across the Atlantic in his self-built catamaran, James Wharram is creating his ‘dream boat’: Mana 24. Here, James’s co-designer Hanneke Boon tells us all about this commemorative self-build kit. Cornwall’s James Wharram is a bona fide celebrity in the catamaran community. In 1955 he claimed a place in ... Building the ultimate ‘trailer sailer’ with epoxy More

We recently came across a great story of how Geoff Morbey built a beautiful red cedar and oak kayak, with materials sourced from his own backyard. Geoff demonstrates what can be achieved with craftsmanship, dedication and WEST SYSTEM® epoxy. It certainly was a labour of love but we’re sure you will agree that the stunning ... Making your homemade kayak look professional with epoxy More

You’ll be amazed at the results achieved by Torie Morley and Toby Hamer in bringing back to life a Fireball dinghy which hadn’t been afloat for 20 years. With the help of layers of WEST SYSTEM® epoxy their efforts were suitably rewarded when they entered the 2014 Fireball nationals (and were given the nod of ... Using epoxy to restore a Fireball dinghy More

Courtesy of www.epoxyworks.com Meade and Jan Gougeon were inducted into The National Sailing Hall of Fame (NSHOF) in October of 2015. Meade and Jan, along with their brother Joel, founded Gougeon Brothers, Inc. in 1969. They were selected because of their pioneering work in the use of epoxies for boat construction and because each are ... WEST SYSTEM founders Meade and Jan Gougeon inducted into hall of fame More

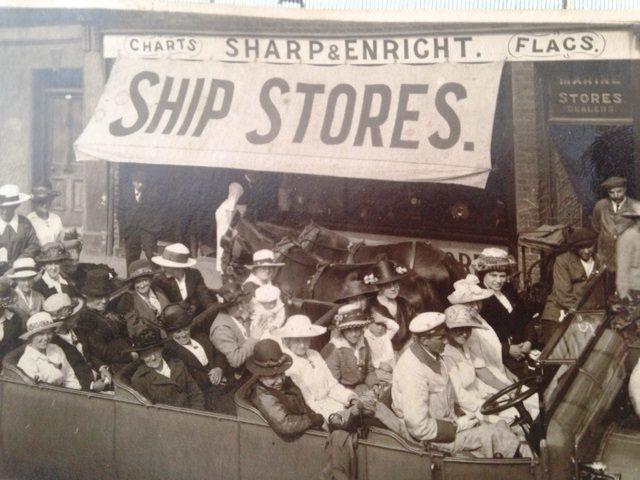

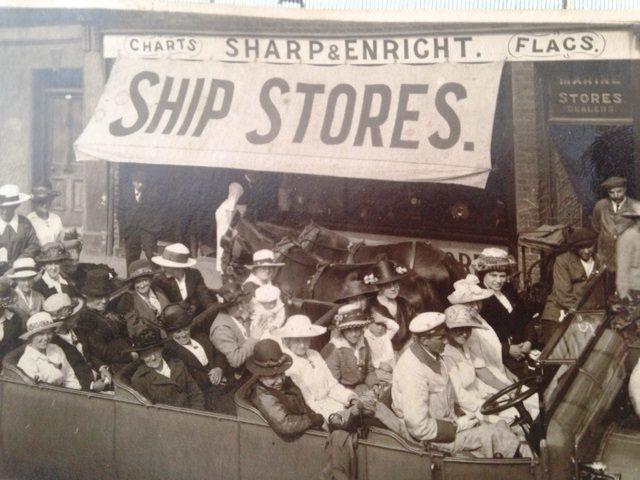

With sources of epoxy knowledge based far and wide, epoxycraft profiles some of the most influential and long-standing. Sarah Sharp, owner and manager of Sharp and Enright in Dover, tells epoxycraft all about her family’s historic chandlery and general merchants. My great, great grandfather took over the business as a sail makers in 1860. But ... All about: Sharp and Enright More

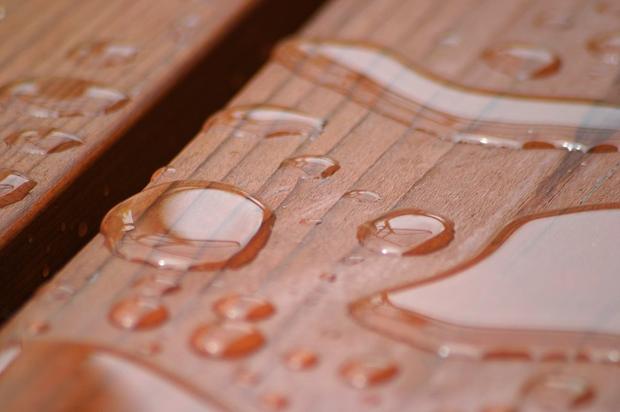

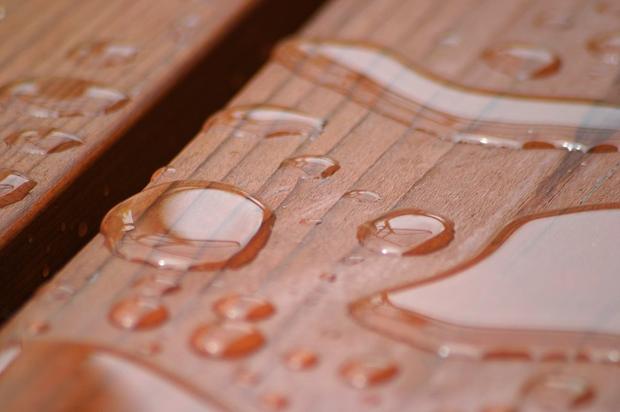

When it comes to protecting your wooden boat from water penetration, defence is the best form of attack. Coating with a marine epoxy like WEST SYSTEM® epoxy is the best way to waterproof surfaces and guard them from any unwanted ingress. But even the most diligent coater might miss a nook or cranny and leave ... Avoid unnecessary wooden boat repairs with marine epoxy More

We recently discovered an article from boat designer John Welsford about his tried-and-tested method for fibreglassing boat hulls. To avoid “spectacular failures”, John advocates using WEST SYSTEM 105 Epoxy Resin® with WEST SYSTEM hardeners for consistently good results. Read John’s proven method here. Image credit: www.wooden-boat-building.nka888.com More

When engineer Mark Raynes found the 1924 MANCHESTER AND SALFORD lifeboat abandoned at Deganwy in North Wales, everyone warned him not to take her on. 14 years, tens of thousands of pounds and a lot of WEST SYSTEM epoxy later, her solid, shining timbers are set to re-enter the waters. “She was a basket case. ... Rescuing the rescuer: giving life to a lifeboat with epoxy More

The thought of renewing double diagonal hull planks strikes fear into the heart of many an expert in wooden boat repair. But Mark Raynes has repaired 3,300 ft of it on his antique lifeboat the MANCHESTER AND SALFORD. In this blog he explains why there’s no need to panic and gives you his top tips ... How to repair double diagonal hull planks More

A romantic dinner under the stars. Is it a five-star hotel? A luxury cruise liner? No, it’s the classic teardrop camper, built using Canadian Red Cedar and WEST SYSTEM epoxy. With near-100% protection against water ingress, effectiveness down to 5ºC, and no need for post curing, WEST SYSTEM® epoxy is ideal for boats. The story, ... Happy campers: Creating innovative constructions with WEST SYSTEM epoxy More

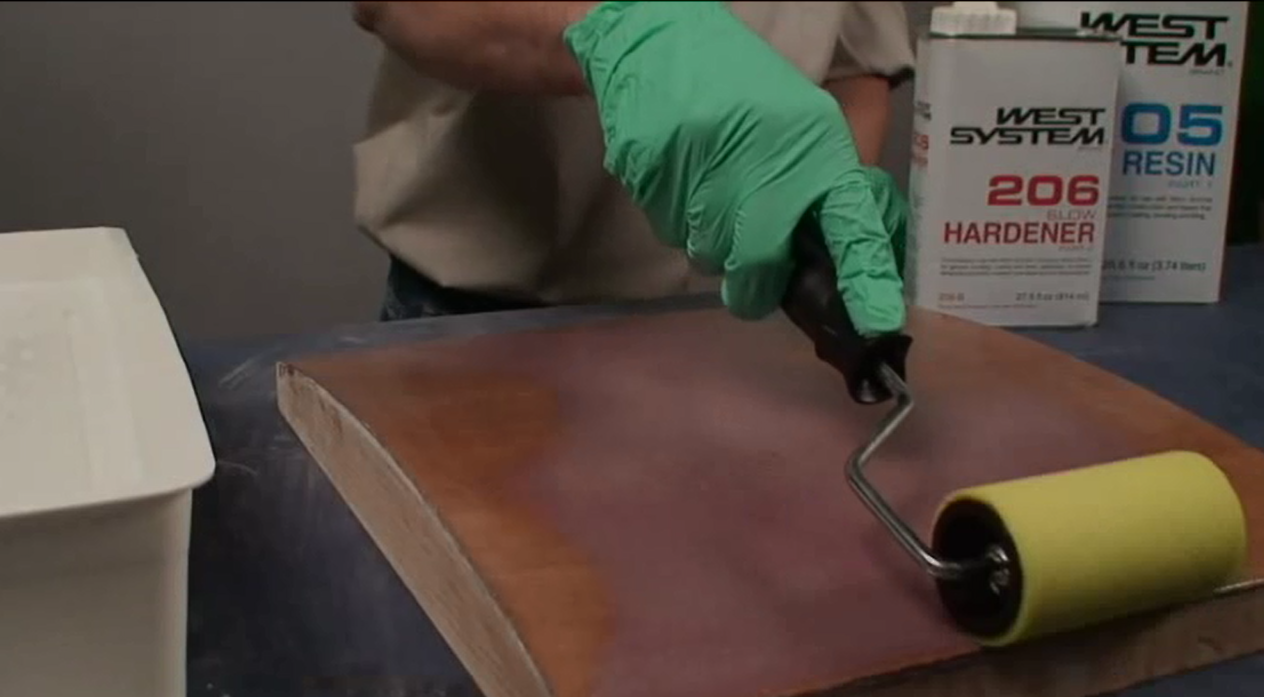

In his informative video, boatbuilder Jason Eke walks the aspiring coater through the process of sealing the deck and gunwales of a strip planked canoe with epoxy resin. Jason describes coating with the final layer of epoxy as one of the most rewarding parts of boatbuilding while he applies a layer of WEST SYSTEM 105 ... How to seal a deck with epoxy resin More

Boatbuilder Agur Paesuld is currently embarking on his latest boatbuilding venture, building a Wharram Tiki 21 catamaran – with nothing but the paper plans. ‘From Paper to Water’ is tagline of his blog, where he documents each stage of his build process. Through a variety of photos and time-lapse videos, we’re following Agur as he ... Reinforcing a keel with epoxy filler More

Robert, of boating advice blog www.lifeonthehook.com, likes to think he’s pretty handy around the boat. But there’s nothing more he dreads than caulking. In fact, Robert hates using caulk so much, he decided to abandon it altogether. When he decided to undertake the task of replacing two hatches on his fibreglass boat, he began to ... Finding an alternative to caulk More

When Miguel Mclawrence decides to undertake a project, he means business. So when he decided to conduct a major fibreglass boat repair he decided to rely on WEST SYSTEM® epoxy. Miguel chose to rebuild his laser dinghy with a honeycomb core and opted to use epoxy throughout the restoration to ensure a long lasting finish. ... Fibreglass boat repair – restoring a honeycomb core More

Marquetry is the boatbuilder’s opportunity to get creative with their craft. But a lot of us are more technical than artistic. Luckily, there are a few quick tips that can turn even the most creatively challenged among us into a master of marquetry. With the right advice and the right products, no boatbuilding task is ... Eight steps to mastering marquetry More

Until very recently, the Wooden Boat Centre in Kotka, Finland showcased the painstaking restoration of Blue Marlin – a classic 1930s Twelve Metre Class yacht. WEST SYSTEM epoxy has played a crucial role in giving her a brand new lease of life. “When we first saw Blue Marlin, she had barely undergone any repair work ... Blue Marlin: where tradition meets “this new, glued thinking” More

With plywood boats susceptible to rot, a solid epoxy coating is essential to fully protect your boat from moisture. This eHow article takes readers step-by-step through the process of sealing plywood using WEST SYSTEM® epoxy. Follow this process to ensure your boat stays protected for longer. More

The most important thing to do when you encounter a hole in your fibreglass boat is to assess the damage thoroughly. If the damage to the skin is larger than 10mm it’s best practice to use a backing to support the wet fabric patch until the epoxy cures. Creating support at the back of a ... Fibreglass boat repair – letter box repair More

Over and over again we see boat builders on forums, support websites and YouTube seeking help to avoid a particularly annoying side-effect of using epoxy, amine blush. This waxy bi-product can have some difficult consequences if not dealt with correctly. Fortunately, there are some very quick and simple methods of getting rid of it. You’ve ... Amine blush: prevention is better than cure More

To compliment his maritime experience, Gary Hunt wanted the chance to build a boat of his own. He joined the Boat Building Academy to start his boat building journey using WEST SYSTEM® epoxy. Firstly, tell us a little about yourself. My professional work has always been involved with the maritime environment, as an aviator for ... Building a strip-plank kayak using WEST SYSTEM epoxy More

Priming with epoxy resin Canadian boat builder Jason Eke takes viewers through the stages of applying fibreglass cloth to a canoe using WEST SYSTEM® epoxy. In video 1 of this two video series, Jason applies the initial epoxy layer and discusses how to make the application process as problem-free as possible using the right tools and ... Cloth up your canoe More

After finding his paddle had begun to chip due to contact with rocks, this blogger sought an alternative to traditional materials to repair and protect his stick. This blog documents the repair of a traditional wooden paddle carried out using thickened WEST SYSTEM® epoxy. By masking up, sanding and shaping a small amount of thickened ... Strengthen that paddle – epoxy repair to a traditional paddle More

In the late 19th and early 20th Century, William Fife’s yachts were the pinnacle of luxury. Today, the style and grace of these classic yachts lives on at Fairlie Yachts, which builds exquisite wooden yachts based on classic William Fife designs, all using modern epoxy construction techniques. Duncan Walker, Managing Director at Fairlie Yachts, tells ... Fairlie 55: evoking William Fife’s age of luxury with modern epoxy techniques More

Eight boats built by the Boat Building Academy’s class of September 2014 were launched for the first time on Wednesday 10th June 2015. Built as part of the class’s intensive 38 week training, each boat was walked from the Academy’s workshops on Monmouth Beach down to Lyme Regis harbour, where a crowd of three hundred ... Crowds celebrate another successful Boat Building Academy launch More

Nick Wunderly always wanted an opportunity to work with his hands but it wasn’t until a chance conversation that he decided to use them for boat building. Further research led him to enrol onto the 38 week course at the Boat Building Academy, enabling him to personally craft a boat to perfection. Firstly, tell us ... Building a Whilly Tern with marine epoxy More

Technical expert and safety fanatic David Johnson discusses the importance of establishing good safety processes when dealing with epoxy resin. Back when I first started using epoxy resin– quite some time ago – I always made sure to develop important safety habits; starting with wearing gloves. Back then, my go-to choice was the cheap and disposable ... Safety first when using epoxy resin: gloves and goggles More

Gary Thompson was visiting the famous Red Sky Craft boatyard in Kotka, Finland, when he came across a simple but ingenious solution to dispensing large volumes of WEST SYSTEM® G/flex epoxy. Allan Savolainen and his team at Red Sky are big fans of WEST SYSTEM G/flex 655 epoxy, using it for all their bonding applications. ... Epoxy pumps: when bigger is better More

This month’s Trade Secret investigates how to avoid leakages when filling a hole with epoxy on a vertical surface. These techniques will help you use your epoxy effectively, keep surfaces clean and avoid waste. Thanks to the laws of gravity, filling a vertical hole is a relatively simple task. However, things become more difficult when ... TRADE SECRET: Filling a horizontal hole with epoxy More

Whatever your boat is made of it’s likely that, at some point, you’ve had to fill and fair damaged areas. Conducting a marine epoxy boat repair, as opposed to using other types of resin systems, creates a strong bond that is water resistant and easy to sand. Filling and fairing with marine epoxy is widely ... Filling and fairing with marine epoxy More

Nexus Marine Corporation, a custom wooden boat building and design services company based in the US, explains how cold-moulding with epoxy resin is perfect for improving the integrity and longevity of your hull. Their website documents each building stage of the Admiral Phormio, a 34’ Odyssey sailing boat, including detailed photos and descriptions throughout. Discover ... Achieving cold-moulding perfection with epoxy resin More

New to boat building, Kris Washington knew what he wanted to achieve for his ‘stitch and glue’ boat – a clear finish allowing the mahogany plywood of the top-decks to show through. Not only is this his first boat build, but also his first experience with bright finishing. Observe Kris’s journey and find out how ... Epoxy your way to a brighter finish with WEST SYSTEM More

Paddleboards, which help you almost walk on water, are all the rage right now. This blogger decides to undertake the task of building two hollow wood Kaholo 12’6” stand-up paddleboards, keeping a step-by-step photo diary of his project. The Kaholo’s are made from Okoume marine plywood, stitched-and-glued together and covered in fibreglass and epoxy, with ... Stand up for epoxy More

Blog writer Gary Willcox claims that applying epoxy to the frame of your sailing boat is “an absolute must” for anyone wanting to increase the performance of their boat. His in-depth article explains the step-by-step method of epoxying the frame of a Hobie 16 together to achieve a stiff, well-sailing boat. What’s more, his techniques ... Epoxy your sailing boat’s frame, one step at a time More

Tim Harrison has always had a passion for the sea. So, of course, the next logical step was to enrol onto the 38 week course at the Boat Building Academy and produce his own high quality boat. Firstly, tell us a little about yourself I’m a retired Civil Servant with many years sailing experience based ... Building “Tucana” with epoxy resin More

Sometimes, a boat comes along that changes everything. This was the case with Diana, a classic sloop built by Walsteds Boatyard in 1998, which used modern epoxy construction techniques from top to bottom. It was a major breakthrough and proof that epoxy could help boat builders deliver faster, stiffer, stronger, more durable boats. epoxycraft asked ... Diana: the boat that changed everything More

Veneveistämö J.Palviainen is a Finnish boatbuilding company based in Kärkölä, Finland. Their boatyard undertakes all kinds of renovation and maintenance including: electrical work, interior design, shaft mounting and coating fibreglass boats. From canoes to sailing boats, the boatyard relies on WEST SYSTEM® epoxy to keep their boats and their business afloat. In the first of ... ‘Pirtuvene’ the traditional smuggler boat: Photo report More

Traditional boat builder, Tim Loftus, believes that wooden boats have a quality that goes beyond functionality and market trends. When given the chance to work on a small project for one of his loyal customers, he was keen to produce something high-quality and long lasting, with that personal touch. Firstly, would you please tell us ... Building “Willow” the Guillemot dinghy using marine epoxy More

Discovering rot on board your canoe is never a good thing. But all isn’t lost. This blogger shares a video of his first time performing a wooden boat repair using an epoxy kit to scrape out and fill in the rotted area, to get his vessel is back to its original standard. More

This blog documents the restoration of the beautiful small boat, ‘Swamp Thing’. With a little care and attention, even something that at one time seemed irreparable, is restored to its former glory with the help of WEST SYSTEM® epoxy. More

Don’s inflatable dinghy was becoming a little threadbare and, without a motor, it was of little use when trying to row in the strong winds. With the help of his team, he decided to upgrade to a ‘stitch & glue’ dinghy. As well as being far more practical, this blogger thought it would make a ... Time for an upgrade More

Epifanes and W. Heeren & Zoon, Dutch distributor for WEST SYSTEM® epoxy, have sponsored eight young students ready to compete in the annual Dong Energy Young Solar Challenge in the Netherlands. The Young Solar Challenge is an opportunity for schools in the Netherlands to teach children between the age of 14 and 18 about practical ... WEST SYSTEM epoxy sponsors Young Solar Challenge More

Whilst giving their sailboat an upgrade, the Ceol Mors became concerned that the tiny little pits and crevices that had been worn into their hatch frames would provide an entry for salt water. Keen to avoid a replacement, Mark began hatching a WEST SYSTEM® epoxy plan to give their frames a new lease of life. ... Hatching a plan with WEST SYSTEM epoxy More

Delamination is a common deck and hull construction problem which tends to get worse if left unattended. Eventually, it can reach a point where the overall structural integrity of the hull and deck may be compromised so it’s really important to know how to perform a high quality with this fibreglass boat repair. Delamination is ... Fibreglass boat repair – a solid solution to delamination More

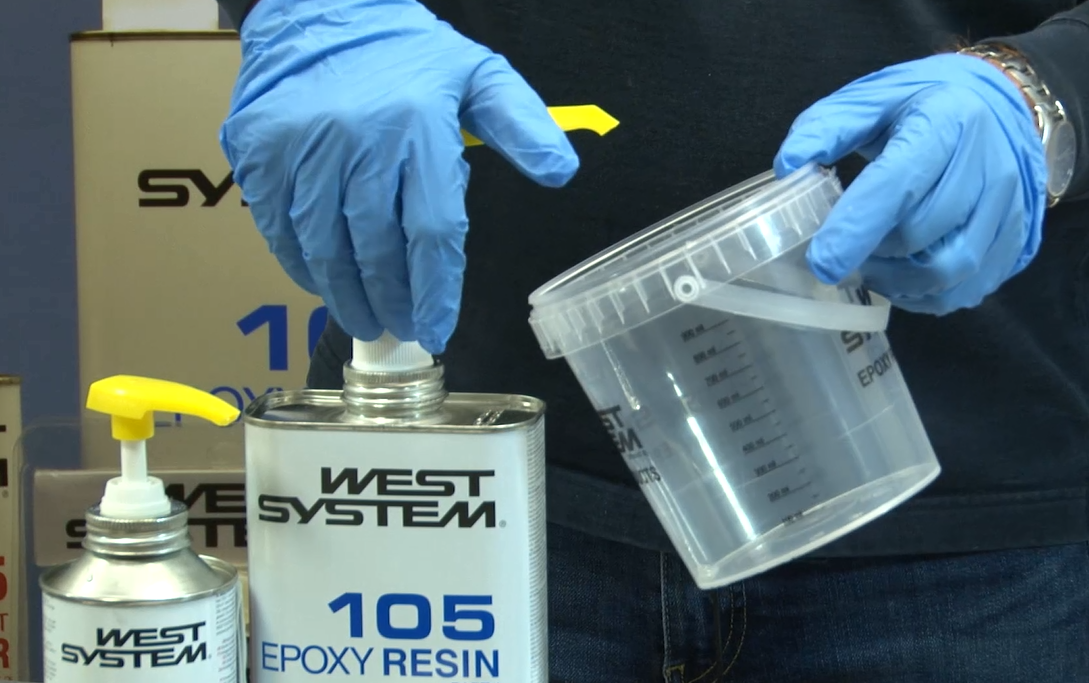

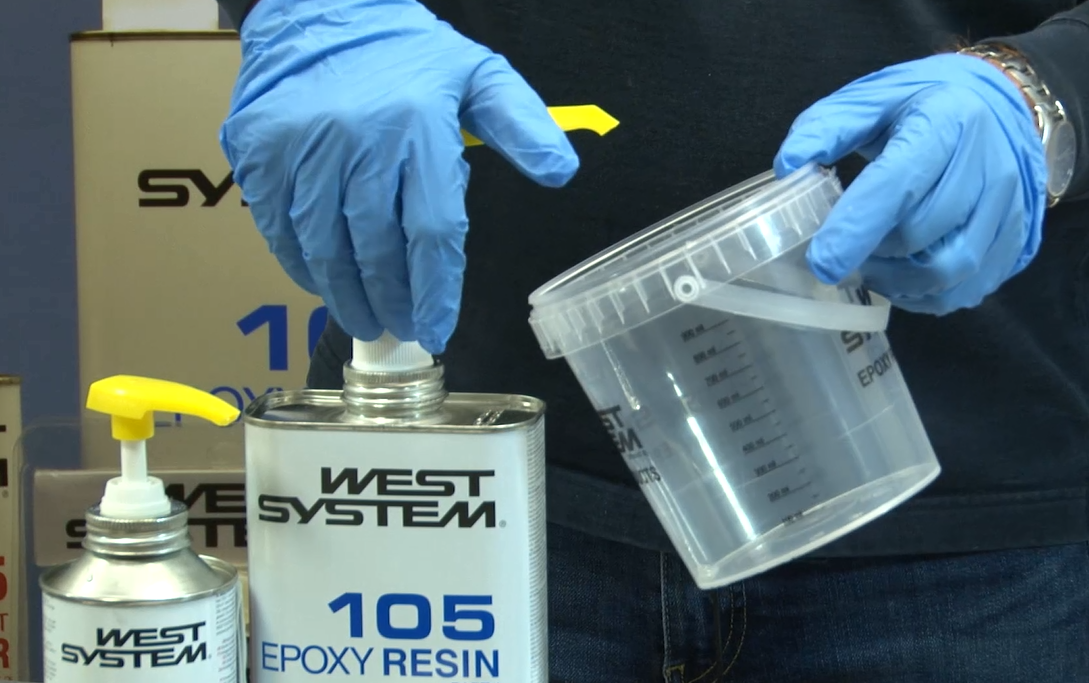

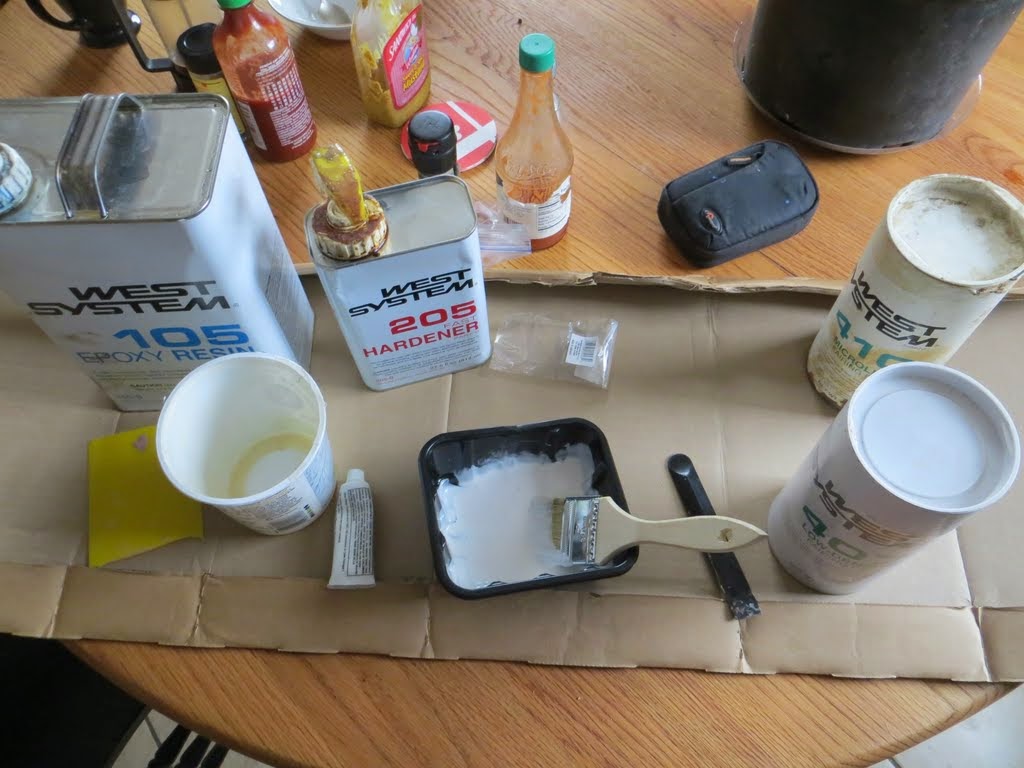

No matter how long you’ve been using epoxy, it’s always worth revisiting the basics to make sure you’re getting them just right. This Trade Secret will provide you with tips and tricks behind dispensing, mixing and adding epoxy filler to minimise waste and get the best results. At epoxycraft, we’ve given readers the chance to learn a ... Back to basics: dispensing, mixing and adding an epoxy filler More

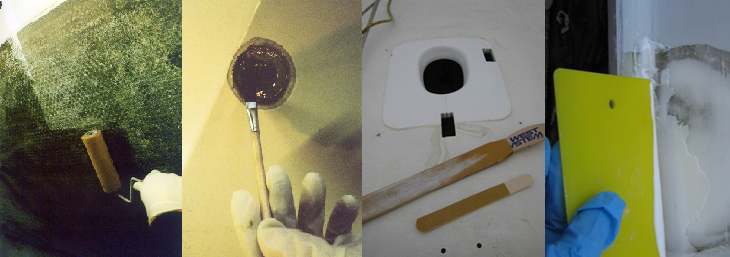

When installing hardware it’s essential that you plan the process meticulously to avoid any safety issues or on-board damage along the way. This Trade Secret shares two methods to keep your hardware secure and watertight using WEST SYSTEM epoxy. At one time, installing hardware may have been seen as a process best left to the ... The perfect seal: installing hardware safely and securely with WEST SYSTEM epoxy More

The strength, resilience and flexibility of epoxy resin mean it’s perfect for everything from crossbows to cracked hosepipes, says Hamish Cook, Technical Advisor at West System International. For over fifty years our heritage has been in boat building, using epoxy resin to transform the way that everything from wooden canoes to fibreglass yachts are built ... Why boats are only the beginning for epoxy resin More

What happens when you combine classic design, the best hardwoods and fittings, decades of boat-building knowledge and WEST SYSTEM® epoxy? The answer is a unique, luxury cruising sloop, the Carolina IV, which looks just as beautiful today as when it was built in 2000 by master boatbuilder Henning Bøgh of Walsteds Boatyard in Denmark. “I’ve ... Carolina IV: creating a modern classic with epoxy More

In 1990, the Jubilee Sailing Trust unveiled ambitious plans to build Tenacious, the world’s largest wooden tall ship, with a view of making it fully accessible to people with physical disabilities. The Trust invited John Birkett the position of construction manager as part of the team to oversee the ship’s construction, which took place between ... Tenacious by name, tenacious by nature – building with epoxy More

After several long trips sat half twisted on his wooden seats, one hand constantly on the tiller, this boat blogger had had enough and said, “That’s it! I’m sitting up front from now on!” This blog details the switch from tiller controls to remote – as readers are guided through the steps taken to make ... Making a stunning steering wheel using epoxy More

Fibreglass boats are known for their low maintenance and durability. However, with structural damage to the stringers a common issue, it’s essential to know how to make a replacement that will last. Although fibreglass boats tend to require less maintenance than their wooden counterparts, they’re not without problems. They suffer from many of the same ... TRADE SECRET: Fibreglass boat repair – replacing stringers More

Nobody wants a leaky boat. So when plywood joints start to deteriorate it’s time to start a wooden boat repair that will make sure your boat stays high and dry. Modern boat builders are frequently looking to produce designs that are lightweight, fast and strong. It’s why many of them turn to plywood. But it’s ... TRADE SECRET: Wooden boat repair – rebuilding a plywood joint More

You’ve got your masking tape to hand and the waterline is ready to be marked up against the boot-top. But when it comes to the crunch, sometimes you just need an expert hand. David Johnson, Technical Operations Manager at West System International, explains how to mask up correctly and what, exactly, it has to do ... Masking up: Best practice when working with marine epoxy More

In the days of ‘Reduce, Reuse, Recycle’, there is always a way to minimise your leftovers. David Johnson uses his epoxy experience to offer his top tips on working with these disposable consumables. As the saying goes, you have to break a few eggs to make an omelette. When it comes to epoxy, you have ... Minimising epoxy waste More

No matter what material your boat is built from, just a single chink in its armour is enough to reduce its lifespan. A weak coating can be a big financial mistake and affect your vessel’s longevity. Gary Thompson, WSI Technical Expert, explains why defending your boat with epoxy is the best form of attack. Time ... Preventing a chink in your armour: coating with epoxy More

The clue is in the name. WEST SYSTEM G/flex is, well, flexible and as this blogger has discovered, that makes it particularly suitable for repairing kayaks. More

Perfect for floating down stream and manoeuvring rapids, a drift boat is an essential build for anyone who loves spending time on the river. This video by Paul Butler offers a construction slideshow of the impressive wooden drift boat design ‘Clark Fork Drifter’ built using marine epoxy. Viewers can watch as Paul’s boat takes shape ... Stitch and glue boat design with marine epoxy More

Boatbuilder Jesse Loynes launched Arbor Yachts to create small luxury crafts that successfully combine speed and elegance. He put WEST SYSTEM® epoxy at the centre of his plans because it makes great business sense. “I remember seeing a lot of smaller, 20-25ft classic yachts that reminded me of VW Campervans,” says boatbuilder Jesse Loynes, when asked ... Arbor 26: Where epoxy construction meets business excellence More

Own a fibreglass boat for any length of time and it’s likely you’ll end up with a few dings or scratches in the surface, or if you’re particularly unlucky even some larger structural damage. Fibreglass boat repairs can seem like a daunting process but, with the help of Boatwork’s Andy Miller’s step by step video, you ... Fibreglass boat repairs with epoxy More

In a world with limited resources, the need for alternative boat building methods is becoming more and more crucial. Renowned boat builder Ted Moore looks at how WEST SYSTEM® epoxy can be used to make use of less than ideal wood in a way that will stand the test of time. With 35 years of ... The future of boat building – strip planking with epoxy and less than ideal wood More

In rough weather, a sturdy hand rail is an essential. That’s why, when sailing adventurers Livia and Carol discovered theirs had become unstable, they began a speedy repair using their drill, screws and epoxy. This post takes readers through the simple steps they took to make this repair. (https://thegiddyupplan.blogspot.com/2010/06/grab-rail.html) More

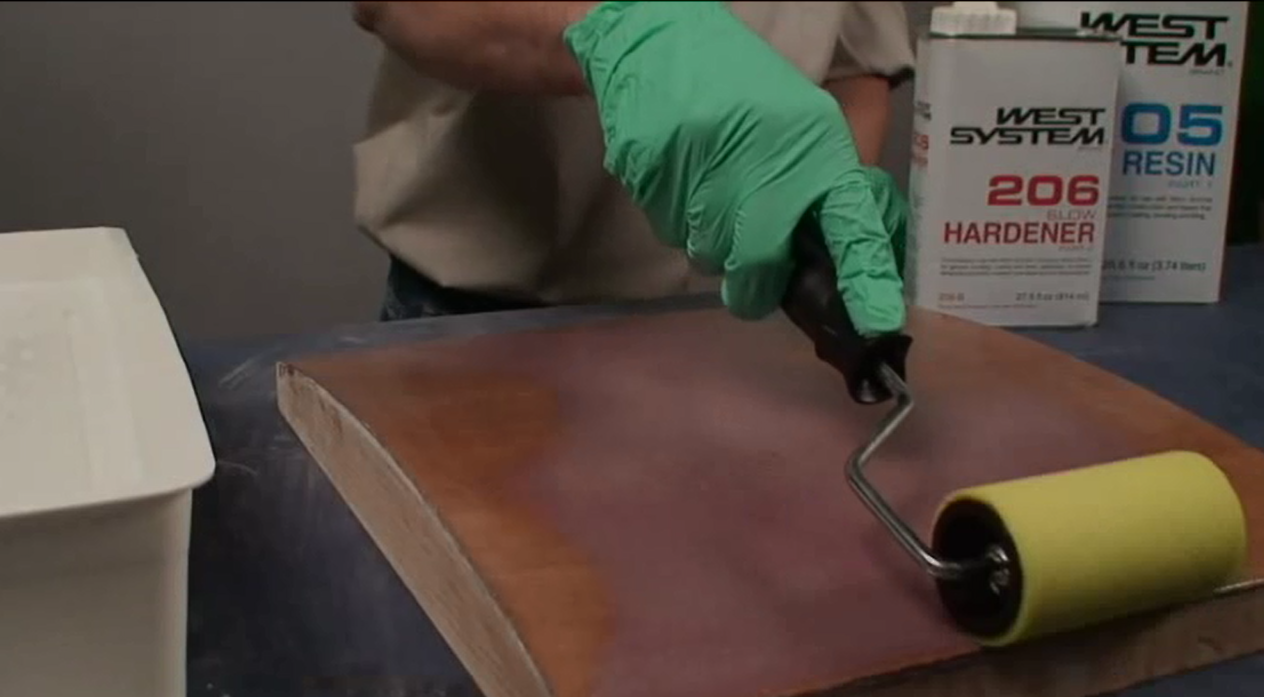

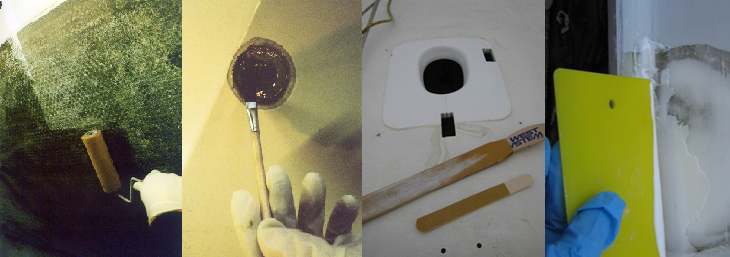

Sheathing is the process of applying an additional surface to your boat’s structure to help increase its strength and durability. Done in the correct way, using the right materials, this can significantly improve your boat’s water resistance and help to protect it against any nasty scrapes or knocks. If you wish to form the strongest ... TRADE SECRET: Sheathing with WEST SYSTEM epoxy More

Epoxy is the perfect solution to help with the common wooden boat repairs. Instead of replacing entire damaged plywood panels, damaged areas can now be cut out and bonded into place creating a strong and resilient wooden boat repair. Boatbuilding with plywood and epoxy has become a popular choice in recent years. The simplicity of this method ... TRADE SECRET: Wooden boat repairs – replacing damaged plywood sections More

Specialist epoxies and innovative techniques have enabled boat builders to construct boats which are lighter and tougher than ever before. David Johnson looks at the evolution of infusion technology which does so much to reduce the compromises of boatbuilding. Large boat/small boat? Cruiser/racer? Sail boat/motor boat? Aluminium/fibreglass? (Or wood? Or composite?) No matter what kind ... Strong and light: the evolution of the epoxy infusion revolution More

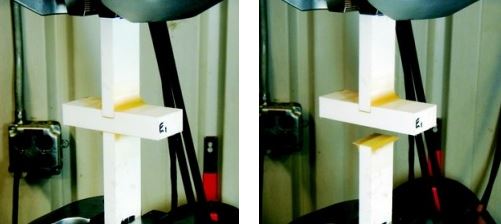

Epoxy fillets can make a bond between components even stronger than the components themselves, ensuring that loads can be transferred between structures and panels effectively, with no risk of stress fractures or other structural issues. In this blog, David Johnson explains what they are and how they work. In Part II, we overview the five ... Better than new: Epoxy fillets More

Danish shipwright Jørgen Jensen prides himself on building boats that push boundaries and when he was commissioned to build the innovative Pi Boat entirely from carbon fibre, he knew PRO-SET® infusion epoxy had a central part to play. As an increasing number of tourists in the Danish capital Copenhagen will tell you, Pi Boat is ... Creating the unconventional with epoxy resin infusion More

The Lone Twin Boat Project used the latest yacht building methods, to turn wooden objects donated by people from across the South East into a seaworthy archive of stories and memories. Jesse Loynes, who worked alongside Mark Covell as one of the lead boat builders, tells epoxycraft about The Boat Project and how epoxy made ... One boat. A thousand stories. More

An epoxy barrier coating protects your boat from moisture and gives you a smooth, stable base which will help secure the finishing coat to protect your boat from sun damage when you’re out and about. So what’s the best way to restore this coating after it’s been damaged? Before starting the application, prepare your surfaces ... Using epoxy to repair barrier coating More

Dry rot is the natural decay process that causes wood to discolour, crack, shrink and – worst of all – lose its strength. Fortunately, when the worst does strike, you can rely on epoxy to save the day. In the bilges, behind cupboard doors, at the bottom of the chain locker or under the bunks; ... TRADE SECRET: Wooden boat repair – repairing localised dry rot with epoxy More

Friday 17th April 2015 Are you looking for a practical way to increase your skills and knowledge of using epoxy? If so, West System International is hosting a special event for boat owners wanting to gain expert knowledge and hands-on experience of using WEST SYSTEM® epoxy to construct, repair and maintain their own boats. The ... WEST SYSTEM EPOXY WORKSHOP The essential hands-on course for any boat owner More

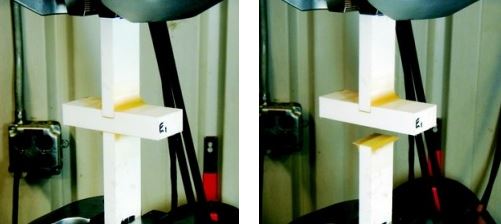

The most popular resin systems for creating glass and carbon fibre composites are polyester and vinyl-ester. But WSI’s technical expert Gary Thompson isn’t a fan. Fibre reinforced composite laminates are well known as being strong and highly durable materials used in many boat building applications. In practice, you start by creating a composite laminate by ... Lighter and stronger: epoxy – the ideal resin for laminates More

David Johnson, West System International technical expert, explains why epoxy should be the only resin system you reach for if you’re looking to effectively sheath your deck or hull. The benefits of sheathing the key structural elements of a boat come down to one word: durability. By using glass cloth and the adhesive qualities of ... Sheathing with epoxy: your only choice of resin More

It’s pretty fundamental; if boats are not to sink their seacocks can’t leak. It’s also one of the reasons why any seacock repair must be done properly and with care. After discovering a loose seacock in his 1981 Nor’sea 27, boat repair aficionado Daniel set to work fitting a new, sturdier replacement using fibreglass and ... Fibreglass boat repair: how to install a raw water seacock More

After discovering a worrying crack in the hull of his boat, sailing enthusiast Mike describes how he set about repairing the damage using WEST SYSTEM® epoxy (http://www.zerotocruising.com/cracking-up). A self-confessed ‘newbie’ when it comes to boat repair, Mike takes readers through the simple steps he took to make his fibreglass boat repair. His blog, ‘Zero to Cruising’, ... Fibreglass boat repair – advice from a repair ‘newbie’ More

It’s something of a well-trodden path for many boat owners on a budget: to follow some simple plans in order to build a competitive boat at a fraction of the cost of buying that’s already been put together. Today, the home build kit boat dream tends to rely very much on modern materials such as ... Kit boats – held together with epoxy resin More

Shipwright Ralph Springett was one of the first people in the UK to use WEST SYSTEM® epoxy products. Forty years later, as he focuses on repairing traditional Thames barges, marine epoxy remains his first choice for light, resilient and reliable repairs. Ralph Springett remembers well the first time he used epoxy resin, four decades ago ... Marine epoxy: breathing new life into Thames barges More

With sailing events taking place all year round, the Isle of Wight makes a perfect home for those with a passion for boat building. After moving to the island, James Lockhart describes how he and his friend Lukasz Stawski were inspired to set up a boat building business – redefining classic boat designs with modern ... Putting some heart into traditional boat designs – by Lockhart Boatbuilders More

At one time, discovering a large hole in your aluminium canoe may have meant admitting defeat with a trip down to the nearest recycling bin. But, with the rising popularity of epoxy products for boat repair, there is now a long-term solution that can means your boat can withstand further knocks and pressure – and ... TRADE SECRET: How to patch holes in aluminium boats with G/flex epoxy More

When faced with a laminate fibreglass boat repair, there are several methods which could prove effective in achieving a decent repair. But nothing gets you quite as close to the original material as vacuum bagging. Although interpreted as a more advanced method, even the least experienced epoxy DIYer can perform a repair using vacuum bagging, ... TRADE SECRET: Fibreglass boat repair: repairing laminates using vacuum bagging More

Once you’ve assessed the damage to your fibreglass boat and carefully prepared your surfaces, it’s time to laminate glass fabric with WEST SYSTEM® Epoxy, as David Johnson explains. In an earlier blog, Preparing for a fibreglass boat repair, we looked at the importance of working out the extent and type of damage you’re facing – ... Repairing your fibreglass boat with epoxy More

In this blog on fixing a crack or hole in your fibreglass boat, David Johnson explains why – before getting to work – you need to carefully assess the damage and plan exactly what’s required. Abraham Lincoln once said that if you gave him six hours to cut down a tree, he’d spend the first four ... Preparing for a fibreglass boat repair More

Paul Calder, son of boat-systems guru and author Nigel Calder, is looking to find out more about boat maintenance and repair. His latest blog keeps readers updated with useful hints and tips for working with epoxy resins. He recommends the best containers for helping epoxy set and which utensils will help to get the most ... Time saving tips when using epoxy resins More

Charlie Hussey, a professional marine carpenter who uses wood to build, restore, repair and upgrade all types of boats, reveals his process for using epoxy on his informative blog: Charlie Hussey – Marine Carpentry. He is currently restoring M.Y Fortuna II. He began the restoration process earlier this year after hauling her out of the ... Marine Carpentry – repair, restoration and boat building More

Is it possible to build a fully functional epoxy dinghy, in 25 hours with a budget of only $250? American boat enthusiast Brian strives to find out, giving readers a chance to pick up his hints and tips on getting speedy results from epoxy on a budget. With each stage of the purchasing and production ... Building an epoxy dinghy – in 25 hours More

Become an expert when thinning your WEST SYSTEM epoxy by reading Brian Knight’s article here. The detailed, scientific and informative article by Brian Knight appeared in Epoxyworks, published by the Gougeon Brothers, all about how to thin your WEST SYSTEM® epoxy. They answer that boat building question on whether thinning your epoxy is necessary, and ... Thinning your WEST SYSTEM epoxy explained More

epoxycraft is a community site so we would like you to take part. If you’ve built a boat or performed an epoxy boat repair using WEST SYSTEM® or PRO-SET® epoxy we can help turn it into an online-published article – completely free. What’s more, it only takes a short five minutes of your time to create an article. Fill out the Your ... Feature your boatbuilding project or epoxy boat repair on epoxycraft More

When the boatyard founded by Danish boatbuilders Jonas Pedersen and Jakob Frost started to grow rapidly in the early 2000s, the pair decided to revive a Danish tradition – and design and build their own racing boat. Here, Jonas details their record-breaking quest for pure speed – and the key role that PRO-SET® epoxy products ... WEST SYSTEM epoxy and the need for speed More

Boat Building Academy students launch the boats that they have spent 38 weeks building as part of an intensive training course at the school in Lyme Regis. At the end of last year, Boat Building Academy students celebrated their success as they finally launched the boats that they have spent 9 months building. Eleven students ... Boat Building Academy students launch the boats they have built from scratch More

A 23ft trailer sailor with built in ballast tanks and buoyancy tanks, four berths, galley and a large roomy cockpit – Adrian Donovan’s most recent (and unnamed) commission leaves little to be desired. The Suffolk based boat builder is used to his boats being described as “drop dead gorgeous” and being complimented on his fine ... Building a 23ft Sailor with WEST SYSTEM epoxy – by Adrian Donovan More

Varnishing the wood trims on your boat is vital for keeping the moisture out of the wood and preventing oxidisation from exposure to UV rays. If the wood is left unvarnished, moisture from dew and rain is drawn into the wood and becomes trapped causing it to swell and discolour. Varnishing also makes the wooden ... TRADE SECRET: Save time varnishing by first sealing timber with epoxy More

Amine blush is a waxy bi-product that appears as epoxy cures. It can prevent varnishes and other coatings from bonding. But, as David Johnson explains, there are simple steps you can take to avoid blush becoming a problem. What is amine blush? As epoxy cures in contact with moisture, a greasy or waxy film known ... Amine blush when working with epoxy: What you need to know More

The art of wooden boat repair has been revolutionised by epoxy. It’s now possible to perform a restoration on a boat in an advanced state of deterioration, without breaking the bank. In Douglas Heckrotte’s article, he tells us how he transformed his old boat into the sleek Flying Dutchman he had always wanted – and how replacing the eroding ... Revolutionise the restoration process: epoxy use in wooden boat repair More

Cutting epoxy cloth can be a messy task. But with Classic Boat’s simple tips, you can’t go far wrong. This short article shows that, when it comes to bonding fibreglass cloth with epoxy, it is possible to remove excess epoxy from the fabric without unravelling the cloth and littering your surface with epoxy threads. With ... How to cut epoxy cloth More

The writers at eHOW have created an easy-to-follow guide to building your own plywood boat using marine epoxy. This guide is registered at skill level easy, therefore any budding boat builders can give it a go! What do you have to lose? Follow the link here to begin building your very own DIY plywood boat. More

Adding a thickening agent, or a filler, to a two-part epoxy mix advances your game to a new level according to Tim Layton, an avid epoxy user. After experiencing some amateur failures when using epoxy he has now become somewhat of an expert and shares his tips on why adding a thickening agent can change ... Thicken your epoxy for more versatility More

Struggling to create strong and resilient bonds between plastics? WEST SYSTEM G/flex Epoxy can help – and a few simple techniques can make your work even stronger. You might not automatically reach for epoxy products when you need to bond plastics together. But WEST SYSTEM G/flex was specifically formulated to generate resilient, powerful bonds between ... TRADE SECRET: Using WEST SYSTEM® G/Flex® to bond plastics securely More

Igor Bzik spent nearly four years building DRACO, a wooden Dragon daysailer, having previously never built anything bigger than a guitar. As he tried to achieve perfection, the project took over his life – and epoxy products became central to realising his vision. Igor Bzik is no ordinary boatbuilder. For one thing, he lives 300km ... “This dragon boat is my obsession – I wanted the best epoxy.” More

Gougeon Brothers, Inc., the manufacturer of PRO-SET® epoxy, is once again a Technical Supplier to ORACLE TEAM USA — the defending champion going into the 35th America’s Cup Match to be held in Bermuda in the summer of 2017. As a technical supplier of adhesives and epoxy resins to ORACLE TEAM USA, the Michigan-based company ... Gougeon Brothers, Inc. named technical supplier to ORACLE TEAM USA for the 2017 America’s Cup More