Projects: ‘Pirtuvene’ the traditional smuggler boat: Photo report

Veneveistämö J.Palviainen is a Finnish boatbuilding company based in Kärkölä, Finland. Their boatyard undertakes all kinds of renovation and maintenance including: electrical work, interior design, shaft mounting and coating fibreglass boats. From canoes to sailing boats, the boatyard relies on WEST SYSTEM® epoxy to keep their boats and their business afloat.

In the first of two photo reports from this boatyard, epoxycraft talks to CEO Jyrki Palviainen and explores their use of epoxy in the recreation of a Finish design dating back to the 1940s.

“The word ‘Pirtuvene’ is derived from boats that were used to smuggle rectified spirits at the time of Finnish prohibition. They came to be known as ‘smuggler boats’, but I prefer ‘Pirtuvene’,” says Jyrki. “In fact, this particular design is based on drawings that were made of these boats back in the 1940s.”

“Here you can see the instalment of the stem and the stern,” says Jykri. “The body of the boat and the decks are made of Finnish pine. We made the boarding through a carvel-built method, where hull planks are fastened edge to edge.”

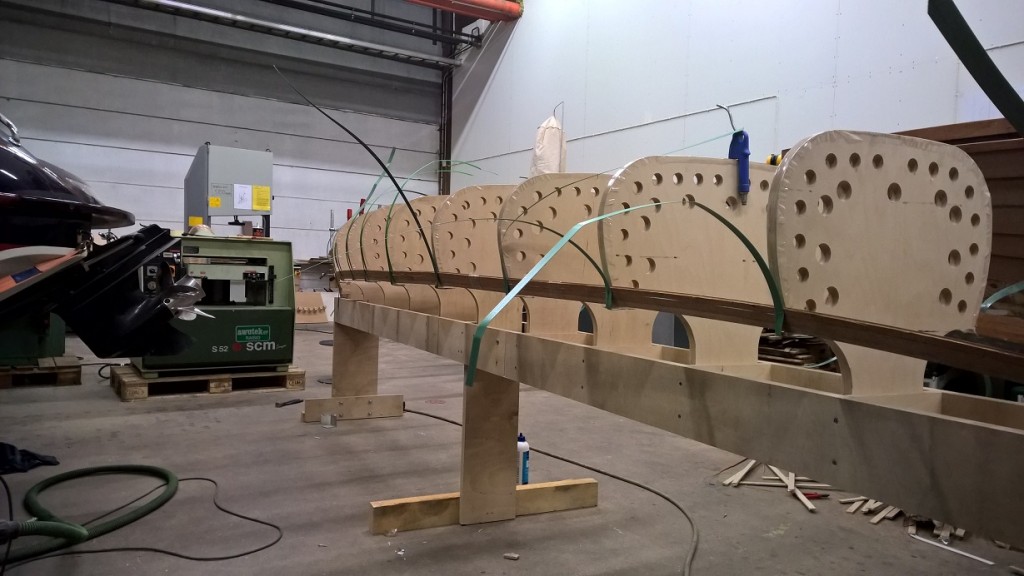

Veneveistämö J.Palviainen installed engine brackets into the smuggler, which run the whole length of the boat, before going on to install the space deck’s body.

“The instrument panel is made of plywood,” says Jykri. “The surface of the panel has a 3.5 millimetre mahogany veneer glued to it. The fair part is Oregon pine but the whole panel was covered with WEST SYSTEM epoxy.

“The frame of the windscreen is made of plywood too, so we also covered it with mahogany and with WEST SYSTEM epoxy to strengthen it,” he says. “The windscreen and the side windows, that you can see, are hardened glass, but we left the top of the windscreen as just glass.”

“The fair part of the floor and deck are Oregon pine and the dark part is 3.5 millimetre thick mahogany veneer, just like the panel. The pine and the mahogany were glued with WEST SYSTEM epoxy to the plywood – we didn’t trust anything else!” Jykri says, “All the veneers and the strips were glued down to the decks using epoxy, staples and pieces of plywood. You can see the technique from the pictures.”

Jykri then used epoxy to fill in 6 millimetre gaps between the deck slats. He mixed WEST SYSTEM 502 black pigment into the filling in order to create a black mass which could be sanded off when cured.

“We made the frames for the front and back seat from plywood. The actual front seat was purchased but the back seat is totally handmade,” says Jykri. “Of course, all of the wood surfaces were coated with epoxy.”

“Because the boarding was made through carvel-building, I used a milling machine to open up the gaps between the boards,” says Jykri. “Then I glued a mahogany strip into each gap using WEST SYSTEM epoxy. I made sure that the strips stayed at the bottom of the gap using pieces of plywood and staples.”

Next, Jykri sanded the boat into shape and then impregnated it with linseed oil. “When the linseed oil was dried up enough, we could paint the bottom of the boat all the way to the waterline.”

“Putting the finishing touches to the boat was one of my favourite parts” says Jykri. “We lacquered the boat with Ryland lacquer using a sprayer and polisher and then all of the mahogany parts were coated with WEST SYSTEM epoxy.” Jykri then gave Pirtuvene a final coat of epoxy before it was ready for the water.

“I love these pictures from the test run! It was a great feeling seeing the boat on the water and an even better feeling when the boat functioned perfectly.”

“I love these pictures from the test run! It was a great feeling seeing the boat on the water and an even better feeling when the boat functioned perfectly.”

For more information, or to contact Jykri Palviainen, see his contact details below.

In the second of two photo reports from this boatyard, epoxycraft explores their use of epoxy in to build a slat canoe.

Veneveistämö J.Palviainen is a Finnish boatbuilding company based in Kärkölä, Finland. Their boatyard undertakes all kinds of renovation and maintenance including: electrical work, interior design, shaft mounting and coating fibreglass boats. From canoes to sailing boats, the boatyard relies on WEST SYSTEM® epoxy to keep their boats and their business afloat.

In the second of two photo reports from this boatyard, epoxycraft talks to CEO Jyrki Palviainen and explores their use of epoxy to build a slat canoe.

“When building a slat canoe, you always have to find the right edge shape using the very first slat,” begins Jyrki.

“We start by gluing the slats together with wood glue. We used some packing strap to help with this, which we stapled to the assistance frame,” says Jykri. “The slat is attached with packing strap and with staples, while the frame stays in shape with tape.”

The bow stem is then sanded in order to achieve the ideal sit between the bow stem and the slate.

“The actual build takes place quite quickly,” says Jykri. “Once the sides are done, the middle is boarded in two sections. Here you can see one side of the canoe is completely boarded in order to find the middle line.”

Then, when the wood glue has dried up, the packing straps and the staples are removed. “Because this canoe is made of dark quay mahogany the staple holes aren’t visible – even after sanding.”

“Once we’ve fully sanded, we give the canoe its first coat of WEST SYSTEM epoxy ,” says Jykri. “After this the canoe is lightly sanded and washed with water in order to remove any grease or amine blush.”

“Next we give the canoe our signature strengthening treatment,” says Jykri. “We cover the canoe with fabric wetted out with WEST SYSTEM epoxy. This is done to the outside and inside of the canoe to strengthen the wood.”

“After this we install inside and outside boards. Then the seats and the support grips – all made from quay mahogany,” says Jykri. “Then that’s it! One finished slat canoe – given extra strength with the help of epoxy.”