Boat Building: How to Build Your Very Own Plywood Boat with Marine Epoxy

There’s nothing quite like the thrill of owning a boat that’s uniquely yours. With WEST SYSTEM® Epoxy, you can build a strong, durable, and eye-catching plywood boat that perfectly suits your style and needs.

The foundation of your boat is the plywood. Choose marine grade plywood, specifically designed for water-based projects. Consider factors like thickness, wood type, and quality. To make your boat even stronger it is wise to consider laminating multiple layers of plywood.

Designing Your Boat

Before you start building, create a detailed design plan. Think about what you’ll use the boat for, how big it should be, and what features you want. You can find lots of online resources and boat building plans to help you get inspired.

A well organised workspace is key to building a boat efficiently. Make sure you have plenty of space to work, preferably outdoors or in a place with good ventilation. Gather the tools you’ll need, such as a table saw, circular saw, jigsaw, router, and various hand tools.

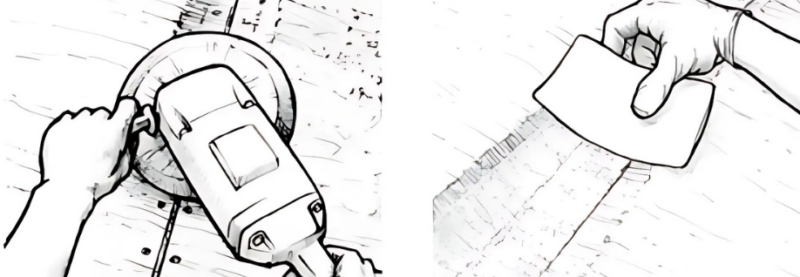

Cutting and Fitting the Plywood

Use your design plans to cut the plywood pieces into the correct shapes and sizes. Ensure your measurements are accurate and pay attention to any curves or angles in your design. Try fitting the pieces together without gluing them first to make sure they fit perfectly.

Bonding the Hull

Start by gluing the bottom planks or frames together using WEST SYSTEM Epoxy. Hold the pieces in place with clamps or temporary fasteners. Let the epoxy dry completely before moving on to the next step. Need help? Our Tech Team is here to assist you.

Adding Decks and Bulkheads

Once the hull is assembled, attach the decks and bulkheads using the same epoxy bonding techniques. Ensure proper alignment and support during the curing process.

Now it’s time to add the finishing touches to your boat. Install essential hardware like cleats, winches, and a steering system. Think carefully about what you’ll use the boat for and choose the right fittings to match your needs. A little extra thought here can make a big difference in how enjoyable your boating experience is.

Finishing and Coating

To protect your boat from the elements such as moisture, apply multiple coats of WEST SYSTEM Epoxy to its exterior. Sand between coats for a smooth finish. Consider adding a topcoat or paint for enhanced protection and aesthetic appeal. Once your boat is complete, conduct a test sail in calm waters. Inspect for any leaks or issues and make the necessary adjustments.

Regular maintenance is essential for prolonging the life of your plywood boat. Inspect for damage, clean the hull, and reapply WEST SYSTEM Epoxy or paint as needed.

Additional Tips for Building with WEST SYSTEM Epoxy

- Preparation: Ensure proper surface preparation before applying the epoxy. Sand and clean the surfaces to remove any dirt, grease, or contaminants.

- Temperature: Pay attention to the recommended temperature range for applying and curing the epoxy.

- Pot life: Be mindful of the epoxy’s pot life, which is the time it remains usable after mixing.

- Storage: Store unused epoxy in a cool, dry place.

- Technical Support: If you have any questions or encounter issues, consult our support for assistance.

For more info on wooden boat restoration and repair you can download our manual here.

Have you subscribed to our FREE monthly newsletter? Sign up here!

Working on a project? Share it with us! Click here…