Trade Secrets: G/flex® 650 vs. 655: Choosing the Right Epoxy Adhesive

When it comes to epoxy adhesives for marine, automotive, and household applications, G/flex 650 Toughened Epoxy and G/flex 655 Thickened Epoxy are two top contenders. Both are renowned for their strength and durability, but each offers unique benefits tailored to specific needs.

G/flex 650 Toughened Epoxy

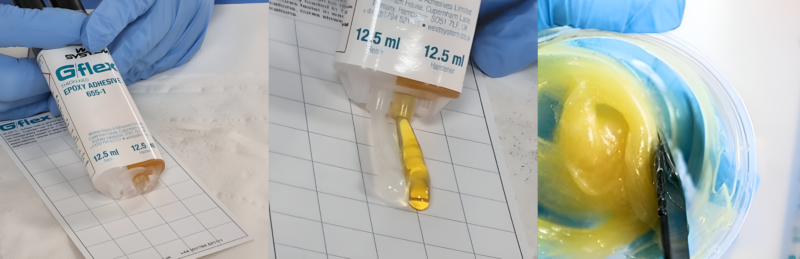

G/flex 650 is a versatile, liquid epoxy with a honey-like consistency. Its fluidity makes it ideal for penetrating and bonding with various materials, including plastics, wood, and metals.

It is ideal for projects requiring a fluid adhesive that can penetrate and bond with various materials. It’s particularly useful for repairing plastic canoes and kayaks, wooden boats, and household items.

G/flex 655 Thickened Epoxy

G/flex 655 Thickened Epoxy is a versatile adhesive designed for applications that require a thicker, more controlled consistency. Its gel-like texture, similar to toothpaste, prevents it from running or dripping, making it ideal for vertical surfaces and overhead repairs.

Shared Features

Both G/flex 650 and G/flex 655 offer a range of benefits that make them popular choices for various bonding applications. These include:

- Strong and durable bonds: Adhere firmly to a variety of materials.

- Weather resistance: Withstand harsh conditions, including moisture and temperature extremes.

- Easy application: Simple 1:1 mixing ratio by volume.

G/flex 650 Practical Applications

- Aluminum boat repair: Its liquid consistency allows for effective penetration and bonding.

- Polyethylene and ABS canoe/kayak repair: Versatile for different materials.

- General bonding: Suitable for a wide range of household and industrial projects.

G/flex 655 Practical Applications

- Vertical and overhead repairs: Its thicker consistency prevents sagging.

- Wetting out fibreglass: Ideal for applications requiring a thicker adhesive.

- Bonding difficult woods: Adheres well to hardwoods like white oak and ipe.

Choosing the Right Adhesive

When deciding between G/flex 650 and 655, consider the specific requirements of your project. If you need a customisable, liquid adhesive, G/flex 650 is an excellent option. However, for projects that require a thicker adhesive or involve vertical surfaces, G/flex 655 may be more suitable.

Additional Considerations

- WEST SYSTEM® offers a variety of kits and sizes within the G/flex 650 and 655 range to meet your specific needs.

- Consult the product data sheets for detailed information on application, curing times, and compatibility with different materials.

By understanding the unique properties and applications of G/flex 650 and 655, you can make an informed decision and achieve optimal bonding results.

Have you subscribed to our FREE monthly newsletter? Sign up here!

Working on a project? Share it with us! Click here…