Projects: Is Brilliant II Their Real-Life Movie Set?

Both born in the UK, Julian and Sharon crossed paths in the Australian film and television industry. As special effects and prop makers, they were the unseen hands behind the magic of the silver screen. Sharon recalls, “In the days before Computer Generated Imagery (CGI), what you saw on the silver screen started with physical objects made by people like us.”

Their work was both diverse and challenging. They were tasked with creating a chocolate bar that could withstand the heat of studio lights for an advertising agency. Additionally, they fabricated a camel for a Toyota Rav 4 commercial. “When Fox Studios set up a backlot in Sydney in 1998, we found ourselves crafting tentacles for the Sentinels on The Matrix, constructing the largest model train set in the southern hemisphere for Superman Returns. We also re-created the original 1977 set pieces for the final Star Wars prequel: Episode III, Revenge of the Sith.”

Their workshops were filled with materials like fibreglass, resins, expanding foams, fillers, plastics, timber, metals, paints, and more. These materials found a new purpose as they took up sailing in their leisure time. “These were often materials we’d use to facilitate boat maintenance or repairs.”

Their first sailing boat was a Compass 29, called Orion, which they sailed around Sydney Harbour on weekends. They also sailed up to the Great Barrier Reef when computer imagery took hold of their industry in earnest and work began to dry up. “It was then that we were bitten by the cruising bug and began searching for a liveaboard yacht.”

What exciting project are you currently working on, and what is the expected completion date?

Brilliant II was not just a boat for Julian and Sharon. It was their home on the water, and a reflection of their adventurous spirit. They had a plan to sail her from Thailand back to Sydney, Australia, and gradually refit her. “Although she came with a long ‘to-do list’, there was nothing that precluded sailing her immediately.”

Brilliant II navigated across the South Pacific, from Hawaii to Australia. It was well-prepared for offshore cruising in Southeast Asia. Following a short haul-out and a handful of minor tweaks, they spent an unforgettable year navigating her back. “Upon reaching Sydney, it quickly dawned on us that this was no longer our home. Instead, Brilliant II was, and the horizon was calling.”

Their journey took them to the southern Queensland port city of Bundaberg. Here, Julian completed some unfinished maritime training courses (Master 5 and MED 2), while working as a shipwright, and beginning studies to become a marine surveyor. Meanwhile, Sharon transitioned from a career in the film industry to one in the media, taking up work with a local newspaper group.

Preparing for a New Arrival: The V-Berth Refit

In their spare time, work also began on Brilliant II. Being marina-based meant they could tackle their refit in bite-sized chunks – cabin by cabin. “We started with the forward head (that’s toilet to the landlubbers), ripping out the damaged veneer and replacing it with ‘wet area’ Lamipanel, as well as sanding back and re-varnishing the existing teak trim.”

Next was the V-berth (forward cabin), where there was similar veneer replacement and original teak restoration to be done, as well as a repair and rebuild of the interior coach roof, renewal of the vinyl-backed headliner, and re-seating and polishing of the opening brass ports. It was at this point in their refit that they discovered they were expecting a baby boy. Suddenly there was a new urgency to at least get the V-berth done!

From Parenthood to Perseverance

Once their son Joshua was born, work on the boat came to a grinding halt – for about 10 years. During this time, they sailed on to Queensland’s Whitsundays, where they settled into family life and their newfound careers. Julian established a marine surveying business, Sharon went to work at the two local newspapers, eventually becoming editor of both.

At this point in their lives, there was barely enough time for sailing, let alone the refit of a project cruiser. For a brief instant, they considered selling their beloved boat. However, when the company Sharon worked for began axing its regional offices, print products, and associated jobs – theirs included – they were ready to take up the gauntlet once again.

“It was the end of 2020 when our refit 2.0 kicked off seriously. The global pandemic had halted any offshore cruising plans, so this was as good a time as any to get stuck in to the (by now) quite desperately needed interior refurbishments.”

Starting where they left off – at the forward end of the main saloon – they ripped out what was left of the veneers, took a belt sander to the holly and teak floor, rebuilt the cabin sides, and began the painstaking process of restoring any salvageable teak, or scratch-building any trims that could not be saved.

Setting Sail

The plan was to continue moving aft to the Nav Station, Galley, and what they call the ‘Hobbit Hole’ (walkway between the aft cabin and main saloon). Initially, they hadn’t envisaged renovating the aft cabin at all, but that’s now firmly on the agenda. Sharon quotes Lady Gaga, “Once you kill a cow, you gotta make a burger” – or as we Brits would say: “In for a penny, in for a pound”.

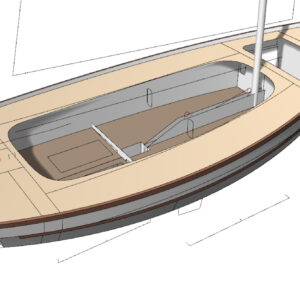

They also hadn’t factored in any external work, but, like the old song ‘Dem Bones’ explains: “the back bone’s connected to the neck bone”, or in their case: “the saloon’s connected to the cockpit” and on it goes.

“The KP 44’s and other vessels of the same ilk (typically built in Taiwanese boat yards), are sometimes lovingly referred to as “leaky teakys”, and Brilliant II was no exception. Internally, tell-tale signs like delaminated veneers and corroded bronze fittings, indicated long-term water ingress, but also like the majority of her sisterships, she had good bones and well, if anyone had the skills to fix her, it was us!”

Sharon and Julian found themselves doing a lot more external work on Brilliant II than they’d perhaps ever bargained for. The main reason for this was also the reason they were refitting in the first place – “those dreaded leaks!” Sharon explains, “There wasn’t much point in beautifying our boat below decks if all that water was going to keep seeping in.”

They had to get to the root of the problem, which meant doing some solid work topsides. This unexpected challenge has brought them to the present date. Due to some not entirely expected discoveries, they found themselves about a year behind schedule, with a possible couple of years still ahead of them.

What materials and tools did you use to create your project, and why did you choose them?

In the early stages of their project, Sharon made a strategic decision to prevent any future recurrence of leak damage. They chose to replace outgoing timber veneers with more water-resistant materials wherever possible. Laminex emerged as their preferred alternative for resurfacing all but the two most visible bulkheads. In retrospect, they could have used it exclusively, even for those.

Contrary to initial impressions of Laminex, which might evoke images of cheap, tacky 1970s countertops or the decor from the vintage BBC comedy series “Only Fools and Horses”, Sharon found that the product has significantly evolved. Over the past 50 years, Laminex has developed modern, satin-sheen, flat whites, and imitation ‘teak-look’ products. Sharon used a combination of these two for their project.

In total, they used 83 individually cut Laminex pieces across the Saloon and Hobbit Hole alone. Each piece had to be firmly glued to the corresponding internal structure.

Moving aft, they worked with stainless steel and Corian in the Galley. These materials were secured in place using either specialist glue or common bathroom sealant.

How to overcome unexpected challenges and setbacks during the creative process?

They initiated their project by using Awlgrip paints for priming and top-coating. However, they switched to International’s Perfection once they reached the significant task of repairing the hull-to-deck join. This task was described as one of their “unexpected challenges”. They had been aware of potential leaks in the hull-to-deck join throughout the refit process, but the scale of the final repair was beyond their initial expectations.

“In fact, if anyone had told us removing two sections of bulwark-mounted genoa tracks would turn into repairing the entire 30 metres (100ft) of hull-to-deck join – not to mention the associated bulwark, scupper and side decks – I think we might have thrown in the towel then and there!” Despite this, they found it impossible to ignore the serious issues they discovered, including cracks, corroded screws, and a timber core that had degraded into vegetable mulch.

How did you tackle the repair, and was it a test of patience and precision?

Julian tackled the join repair with a hammer, chisel, and a great deal of patience. He removed the damaged material to a minimum depth of two inches, or the entire height of the bulwark in load-bearing areas. The voids were then filled with WEST SYSTEM® 105 Epoxy Resin®, mixed with the 206 Slow Hardener® and the 413 Microfibre Blend (for EU customers this would be the 403 Microfibres Blend), suitable for their tropical climate.

Julian chose this combination of materials primarily for its structural strength. He explained, “You can also tailor the mix to suit its application, changing the viscosity from thick to thin depending on what you’re trying to achieve. The 413 Microfibre mixes really easily with the resin, combining well and quickly, and although you don’t get a super long working time in hotter climates like ours, the cure periods are always fairly consistent, so you always know what you’re working with and there are no nasty surprises. It also sands easily within the first 24 hours, but any longer than that and it becomes extremely hard so there’s a lot more effort required, which is something to bear in mind when planning your work flow.”

All of the WEST SYSTEM products used in the project were sourced through their local agent, Shaun Kerrigan, at Proactive Marine in Cannonvale. Shaun was consistently able to supply the quantities they needed, whether it was the small five-litre kits they initially used, or the larger 20-litre drums they required as the job expanded.

Ready to set sail? How will you maximise your fully restored boat?

Their plan, once the refit is complete, is to take her cruising. The timing and location of their departure will depend on how much longer it takes to complete the tasks they initially set out to do.

“It’s worth mentioning that we could have completed this project faster if we’d been on a hardstand rather than in the water and worked on the project full time.” Instead, they have been balancing the refit with their regular jobs and family life, essentially treating it as a second job. After a challenging nine-months stint tied to the dock, they made a commitment early on to keep sailing whenever possible. “I wouldn’t necessarily recommend this approach to anyone else – it’s just what’s worked to some degree for us.”

Do you have any other exciting upcoming projects you are planning to work on in the future?

“I think this is more than enough for now! In the future our exciting project will be sailing – and no doubt continuing to fix Brilliant II in whatever exotic location we happen to have sailed to. After all, that’s boats right?!”

What advice would you give to anyone else looking to build/restore a boat?

When asked about advice for others looking to restore a boat, Julian and Sharon had a good laugh and said, “don’t do it!” But they were only joking. They want people to know that restoring a boat is a huge undertaking. It’s going to take longer, and cost more than you think.

Even if you’re doing the work yourself, it’s not going to be cheap. Time is money, and your time is valuable.

They also stressed that this is a labour of love. You’ve got to love the work and your boat to take on a project like this. Julian’s advice? Always read the instructions, especially when it comes to materials. And remember, “measure twice, cut once.” You can’t be too careful.

Lastly, they recommend documenting the process. Keep a journal, take photos, make videos. They’ve been sharing their journey on their YouTube Channel ‘The Sailing Adventures of Brilliant II’. It’s a great way to share knowledge and keep a record of this huge achievement. It’s a big part of their lives, and they’re proud of what they’ve accomplished.

Follow Sharon and Julian on their social handles here:

Have you subscribed to our FREE monthly newsletter? Sign up here!

Working on a project? Share it with us! Click here…