Boat Building: A Director’s Boat Building Journey

I presently hold the position of director at medical clinics situated across various locations in the Netherlands. The primary motivation behind building “anything” was the realisation that in contemporary times, we often fail to witness tangible outcomes of our efforts.

The human mind is a fascinating tool, capable of processing complex monetary figures, numerical data in Excel sheets, financial reports, and career advancements. While it can be challenging, it’s also an opportunity for growth and learning. At the end of each day, we can reflect on our progress and feel a sense of accomplishment for our efforts.

This is precisely why a sense of accomplishment accompanies activities like lawn maintenance or household cleaning. The noticeable results resonate with the mind, eliciting a rewarding release of dopamine. Acknowledging this phenomenon, I dedicated a modest space to a hobby room and delved into the art of woodworking. Although my initial projects, such as cutting boards and iPad holders, were relatively straightforward. My zeal evolved for the intricate nature of wood as a material.

Discovering that the cutting board I made from an olive tree will endure long after my lifetime. This realisation has added a layer of satisfaction to the entire experience.

After this phase, a strong inclination to undertake more substantial projects developed. Unfortunately, my tools, skills, and knowledge were insufficient for handling large woodworking jobs. It was at this point that I discovered resin pour tables, presenting a promising avenue for exploration.

It was kind of like stumbling upon a cheat code in woodworking. You know, not everyone can whip up a chair. But with epoxy, you can still make something that turns heads without being a woodworking maestro. So, that’s how I dipped my toes into the world of epoxy—actually, a whole lot of epoxy.

I have crafted numerous resin pour tables. This experience has allowed me to gain enhanced skills and tools. Now, I feel the urge to tackle a larger project. That’s when the idea hit me: why not build a cedar strip canoe?

My journey with resin tables serendipitously equipped me with skills. These skills were surprisingly relevant to canoe building, particularly when it came to using epoxy for enhancing the visual appeal.

As a newcomer to woodworking, I took on the project of building a canoe. By the time the canoe was finished, I had graduated from my beginner status. Along the way I gained a wealth of knowledge and experience. The process was both educational and transformative.

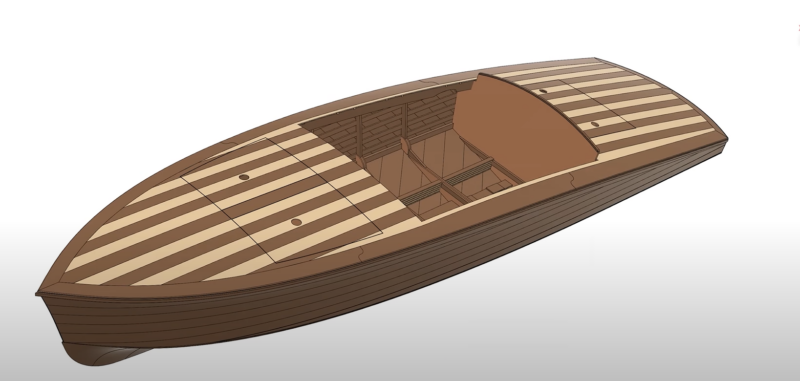

The next chapter of my journey was to construct a wooden runabout. To me, these are not just boats, they stand as exquisite pieces of high-end furniture. Their ability to float is an added feature. Even if displayed behind glass, they maintain their status as works of art.

I realised that to construct these wooden runabouts, you must be more than a skilled woodworker; you really have to be an expert.

You know the saying, “if you can build a boat, you can build anything”? Well, I wasn’t quite there yet. So, I thought it best to start smaller and focus on improving my skills. That’s when I decided to build a river drift boat, complete with a custom helm and an electric engine.

This project was not only a great deal of fun but also a fantastic learning experience. It significantly improved my woodworking and boat building skills. It might have been a smaller project. But it brought me a step closer to my goal of becoming an expert craftsman.

What are the Current and Past Projects You’ve Worked On?

Right now, I’m in the midst of a fascinating project. I’m building a 7.7-meter slipper launch equipped with an inboard electric engine.

Building Ferrari’s all electric wooden boat (Part 1)

Can you share details about the materials and tools used in your projects, including any WEST SYSTEM products?

Discussing the tools used in boat building indeed covers a broad spectrum. In woodworking, the quality of the tools often directly correlates with their price. For instance, opting for a sander that costs a quarter of a professional one might seem like a bargain. But the additional 100 hours you’ll spend sanding the hull negates any initial savings. This principle applies to almost all tools, especially in today’s climate where wood prices are soaring. Using a cheaper, less accurate tool can lead to wastage of valuable hardwood, turning potential masterpieces into mere firewood. It’s a classic case of false economy.

How Does Material Quality Impact the Success of a Project?

The importance of material quality cannot be overstated. When I first began creating my resin pour tables, I lived by the motto “epoxy is epoxy”. I chose the most affordable local brands. However, I learned a hard lesson when I had to spend eight hours stripping epoxy-infused fibreglass from my canoe. This was due to extreme clouding on the surface, despite using a slow hardener in low humidity conditions. This experience taught me that not all epoxies are created equal. Choosing the right one can make a significant difference in the final result. Lesson learned.

Indeed, epoxy is a crucial component in boat building where there’s no room for compromise. After all, “epoxy is forever”. It’s essential to have an epoxy that offers consistency, repeatability, and predictability. This ensures the longevity and quality of the boat.

Now, I exclusively use WEST SYSTEM® Epoxy for all my projects. I may not be a chemist. But I understand that there’s a wealth of scientific research backing the quality of WEST SYSTEM Epoxy products. Sure, I could save a bit by using a cheaper epoxy, but the risks are too high. Imagine if the keel laminations start to delaminate after 10 years. Or if the so-called UV resistant epoxy isn’t as resistant as it claims to be. Worse still, imagine if the epoxy cracks or doesn’t seal perfectly. This could lead to water seeping through the encapsulation and causing the planks to rot. These are risks I’m not willing to take. I’d rather play it safe than be sorry later.

Overcoming Unexpected Challenges and Setbacks in Projects: What Were They and How Were They Handled?

Indeed, finding specific information about boat building can be a bit of a challenge online. This is particularly true when looking for details on how to fair the keel and frames. However, there are resources out there. For instance, there are videos and articles that discuss the process of fairing a hull, which involves similar principles. There are also resources that provide insights into the process of fairing the keel. It’s all about knowing where to look and being patient in your search.

Indeed, it can sometimes feel like there’s a secret guild for boat builders. The only perceived way in is through something as drastic as marrying one of their daughters. While there are written resources available, like those from Glen-L or the Gougeon Brothers On Boat Construction from WEST SYSTEM Epoxy, it’s often much easier to understand complex processes like these through visual aids like videos. It’s a bit of a challenge. But it’s all part of the journey of becoming a more skilled within the industry.

Dan Lee is currently constructing a 1/16 scale model of his new design, “Temptress” and is documenting every step. This will be the first video to showcase the construction of a high-end boat from start to finish.

Staying Informed and Engaged in the Boat-Building Community: Tips and Strategies

Boat building, particularly at the hobby level, seems to be stuck in a time warp. Most plans still being hand-drawn blueprints. These blueprints are filled with jargon that can be quite baffling for beginners. I recall purchasing the plans for a ‘Barrelback’ and being utterly perplexed as the blueprint was indecipherable!

Fortunately, Dan from Dan Lee Boat Building has brought boat building into the 21st century by creating 3D plans. These plans allow you to view every single part of the boat with precise dimensions. He’s even gone the extra mile by providing a timber list and CNC cut plans for frames. Additionally, he has provided a comprehensive start-up guide.

In addition to these resources, I also frequent several active forums such as boatdesign.net, Glen-L forums, and woodenboat.com forums. These communities are generally very supportive and helpful, except when the topic of encapsulating the boat with Epoxy comes up – then things can get a bit heated!

Finally another project I follow is Tally Ho. This is the greatest boa building series that i’ve ever seen. It is almost like a Netflix series revolves around a guy that tries to build an impossible wooden boat with no means.

Do you have any other projects you plan on working on in the future?

I hope to commission with a naval architect to bring to life the plans for a concept boat, specifically the one featured here: https://www.designboom.com/technology/zebra-electric-wooden-boat-05-31-2017/ . This unique design, known as the “Zebra”, is a testament to the innovative vision of Parisian industrial designer and engineer Dimitri Bez. It’s a boat that beautifully marries tradition with modernity, featuring a minimalist design powered by

electricity. Using materials like dark wood and leather, the Zebra is a perfect blend of classic aesthetics and contemporary technology.

Essential Tips for Beginners Starting a Boat Building or Similar DIY Project?

While I’m still learning the ropes in the world of wooden boat building, I wouldn’t presume to offer advice just yet. However, I do have a small cautionary note: boat building is highly addictive so make sure that you don’t neglect your loved ones. Moderation is the key.

Order WEST SYSTEM Epoxy Products in the Netherlands:

Epifanes/W.Heeren & Zoon BV

Postbus 166, 1430 AD Aalsmeer.

T: +31297360366

F: +31297342078

E: info@epifanes.nl

Or if you are based anywhere else you can find your local stockist here: https://eu.westsystem.com/where-to-buy/

Connect with Serdar Bas: Explore His Social Media Profiles

Have you subscribed to our FREE monthly newsletter? Sign up here!

Working on a project? Share it with us! Click here…