When Igor Marukha wanted to fulfil his ambition of building his own canoe, he didn’t take to the water – but to the internet. Today, he runs his own successful boat building company, NeoBoat, and WEST SYSTEM® epoxy products are never far from hand. Boat building, like most things, has been transformed by the internet. ... Starting a canoe business – by surfing the web More

David Johnson urges people new to epoxy to attend WSI’s Epoxy Workshop course. Or, at the very least, to read the manual. If you ever read a technical computer forum you may have seen the acronym ‘RTM!’ being used to pass comment on people who have asked a particularly basic question. It stands for ‘Read ... The best way to avoid mistakes when using epoxy More

Bailey Boat Cat is a life jacket wearing, sea breeze loving Siamese cat – who blogs about his life cruising around the Italian coast. It seems that Bailey’s family have been working on multiple projects to renovate their vessel to ensure it’s ready for cruising safely and comfortably. He recently blogged about his ‘dad’s’ love ... Bailey Boat Cat: an unusual epoxy user More

How to thin your epoxy and what to consider before you do Reducing the viscosity of WEST SYSTEM® epoxy by adding a solvent, can be tempting. It becomes easier to roll out; it penetrates more deeply into porous surfaces such as partially rotten wood; and it saturates faster into materials like fibreglass fabric. But – ... TRADE SECRET: Thinning epoxy: Best practice guidance for reducing the viscosity of WEST SYSTEM epoxy More

WEST SYSTEM® epoxy is an invaluable resource for creating a clear coating that showcases both the beauty of the wood grain and gives you four times the thickness of a single coat of polyurethane. In just a few simple steps, you can achieve a beautiful, bubble-free wooden surface using epoxy resin. Bubbles are a frustrating ... How to create the perfect epoxy coating on wood More

Winter is a time when many boaters migrate away from the water and into the workshop or boat shed in order to repair their vessels or even to build their next ones. If you’re one of these people and you are using marine epoxy, you will most likely know that it’s very sensitive to temperature ... Marine epoxy in cold weather More

Smoothing edges and removing unwanted irregularities are the final steps to giving your boat a perfect finish. A cabinet scraper is the perfect tool for the job, as it will remove all traces of irregularities from the surface of an epoxy resin coating. What’s more, a cabinet scraper is quick and relatively simple to make ... TRADE SECRET: How to make and use a scraper on epoxy resin More

According to Kurt Hughes, a lack of cash does not need to be the end of the road when it comes to building your dream boat. In fact, he insists you can get more boat for your money by building a plywood and epoxy model instead of a composite one. The multihull designer says you ... Build a boat without breaking the bank using plywood and epoxy More

Powerboat driver Bob McCarthy explains why epoxy is now his only choice – whether he’s racing his Formula 3 Bernico in Offshore circuit Racing or breaking water-speed records. People often ask me what the experience of racing powerboats is like. I’ve been doing it for 25 years and I’m still not sure I really know ... Stronger, lighter, faster – using epoxy for powerboats. More

Top tips for installing teak decking panels using PRO-SET® ADV 170 Adhesive and utilising vacuum bagging techniques. Modern prefabricated teak decking panels are manufactured from accurate jigs that allow speedy, clean, final fit installation at the production boat manufacturers. PRO-SET ADV 170 Adhesive is a highly developed thickened, easy to use, 1:1 mix epoxy adhesive that is ... TRADE SECRET: Installing teak decking panels using vacuum bagging More

Business and life partners, Simon and Cat Holman, began their artisan fishing business by designing and building Kensa, an unpowered fishing boat. With Kensa complete, and an integral part of the business, we speak to the couple about their venture and the creation of Kensa. Firstly, tell us about yourselves. Cat: Simon began his career ... Starting an artisan fishing business by Simon and Cat Holman More

Known for his superior knowledge and technique with epoxy, carbon and fibreglass, Russell Brown explains why he’s sticking to WEST SYSTEM® Epoxy in his latest blog post found on ‘Ports Townsend Watercraft Blog’. Russell has over 40 years of experience with boat building and repairs. He has sampled many different brands of epoxy, but insists ... We ‘stick’ with epoxy More

Norman Ralph, writer of ‘Tanks a lot, part 3’, taken from ‘Good Old Boat’ magazine explains how he repaired the diesel tank of his boat ‘Bluebonnet’ using WEST SYSTEM® epoxy. Marine epoxy can cure numerous elements of your boat to prolong its life on the water. Norman is a loyal WEST SYSTEM epoxy user and it ... The epoxy ‘Cure’ More

Prevention is the best solution to keeping your boat healthy and on the water, according to the writers and boat fanatics at ‘Compass Marine how to’. Every boat has a ‘core’ that is in danger of becoming saturated and eventually rotting. Preventing this happening with the help of WEST SYSTEM® epoxy can hold your vessels ... Preventing core rot with WEST SYSTEM Epoxy More

Michigan based, sailing enthusiast and writer of ‘my2fish’ blog, shares his process on repairing wooden components of his three boats using WEST SYSTEM® Epoxy. Restoring the wooden parts of all three of his boats, two Sunfish and one Super Porpoise, the blog post follows the wooden boat repairs of two sunfish rudders and one daggerboard. The ... Sailing enthusiast trusts epoxy for his wooden boat repairs More

The creators of the Ocean Explorer C-60 catamaran value quality above all else – and PRO-SET® epoxy products play a central part in their vision. Peter Granholm was visiting a shipping interiors company in his native Finland recently when a poster caught his eye. “It was a quote from Benjamin Franklin,” he says. “’The bitterness ... “If you want top quality, epoxy is a no-brainer.” More

WEST SYSTEM G/flex® speciality epoxy is an exceptionally strong epoxy, designed to provide unbeatable grip to plastics, glass, masonry, fibreglass, wood and metals – including aluminium. So if your aluminium boat is in need of a little TLC, G/flex is a very wise investment. As well as effectively repairing leaky rivets and seams, it creates ... TRADE SECRET: How to fix a leaking aluminium boat with epoxy More

Sustainable living is the future. This pair of boat-builders, Simon and Cat Holman, wanted to live sustainably by fishing locally, after hand-crafting their very own boat. Simon and Cat showed that not only is it achievable, it is also feasible even with a limited space – provided the right materials are available. By using epoxy ... Building a sustainable future: hand-crafting your very own boat More

By keeping these simple ideas in mind, you can make your work with epoxy resin as straightforward and reliable as possible. Prepare to succeed Before you begin using any WEST SYSTEM® epoxy products, ensure your workshop is clean, dry and free from dust. The ideal temperature is 20-22°C, which means you should feel comfortable wearing a ... Four expert tips to use epoxy resin effectively More

John Rousemaniere once said “the goal is not to sail the boat, but rather to help the boat sail herself”. This is exactly what Mat Gravener has done, performing a wooden boat repair and restoration on his 1940’s Broads Cruising Yacht the ‘Lady Perfect 9’ to her eloquently named former self. Using WEST SYSTEM® Epoxy, Mat ... Wooden boat repair – helping the boat to save herself More

By keeping these four kitchen cupboard favourites in mind, you’ll ensure your thickened epoxy is the right consistency, every time. Thickened epoxy – a mix of resin and hardener with filler added – has a huge range of uses. By varying the amount of filler you use, you can alter the consistency of the epoxy ... What have peanut butter, ketchup, syrup and mayonnaise got to do with epoxy resin? More

Sam Collins has been working hard to achieve his vision of ‘Karen,’ the perfect boat. Currently under construction, Sam is building an 18’ Alden Sloop, which is strip planked in western red cedar. When completed, she will have cold-moulded khaya outer veneers. We took a look at how the project is going so far. Firstly, ... Using epoxy to build the perfect boat — by Sam Collins More

Set up in 2012, Boatwork Ltd is run by married team Mark and Julie Bestford with help from their mascot and canine companion Hassle. The company focuses on the management, maintenance and repair of their various clients’ boats. Recently tasked with a wooden boat repair which involved replacing a GRP sheathing with an epoxy one ... The wooden boat repair and renovation — by Boatwork Ltd. More

Marine epoxy is a thoroughly useful material to have with you not just in the boatyard but out to sea as well. It can fulfil any number of purposes when you’re out and about, including small repairs and filling. Sailing Today have recently run a feature on how to go about choosing the most suitable epoxy for ... 6 things to think about when buying marine epoxy More

Willie Crear has been a boatbuilder and racer for over 50 years. Find out why he uses PRO-SET® epoxy on his projects as opposed to cheap polyester resin on his website. And see more about his I-20 and M-20 builds. Why Epoxy Resin, not Polyester? – Willie Crear, boatbuilder (http://www.williecrear.com/why-epoxy-resin-not-polyester.html) More

Fibreglass boat repair, the ultimate challenge for WEST SYSTEM epoxy, can it bond them closer together? This Rhode Island couple’s new GRP boat-building project is the ultimate challenge for any relationship. Follow them as they talk through all the trials and tribulations of fixing up a 1967 Pearson Ariel fibreglass boat. From avoiding boat-pox and removing a rudder to scraping ... Fibreglass boat repair – from scraping paint to naming More

This week’s featured project from an epoxycraft reader comes from boatbuilder Gary Thompson, who’s based in Romsey. His Herreshoff Haven 12 ½, called Lashanna, took him months to build. We caught up with Gary to find out how he did it. How did the project come about? The project came about during my year at Lyme Regis ... My Herreshoff 12 ½ day sailing boat with WEST SYSTEM epoxy More

WEST SYSTEM Six10® epoxy is conveniently stored in a self-metering cartridge, providing permanent, waterproof results for all your adhesive needs – from filling holes and cracks, to bonding fiberglass and metal. Check out this video for more information and yet more reasons why WEST SYSTEM epoxy products could be right for you. Got a question about basic boat repairs? ... Using WEST SYSTEM Six10 Thickened Epoxy Adhesive More

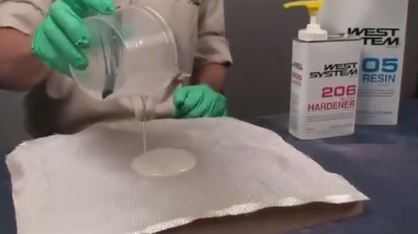

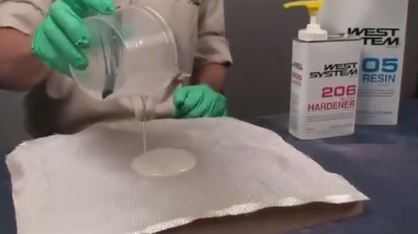

If you need to lay up a fibreglass canoe hole, the WEST SYSTEM® Vacuum Bag demonstration in this short two-minute video will offer you a viable solution. Our technical advisers briefly run through the materials you will need, and how to go about this fibreglass boat repair. You’ll be paddling your canoe again in no time! ... Fibreglass boat repair – fixing a hole in your canoe More

You would think that bonding plastics together would be impossible, but using WEST SYSTEM® G/flex® Thickened Epoxy Resin and Hardener proves that you can. The epoxies provide permanent waterproof results, using a simply one-to-one mix ratio, making it easy for even the least confident user. The strength of the WEST SYSTEM epoxy products is second to ... G/flex epoxy: we put it to the test More

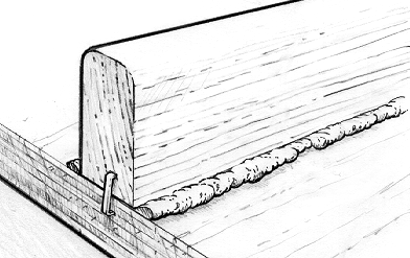

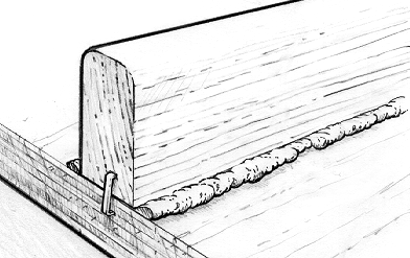

It’s really quite tricky to find naturally occurring turns these days, where the grain is the shape you need to make a knee, or breasthook. But never fear! Richard Toyne at Classic Boat has explained how you can manufacture your own knee by bending thin layers of wood to the right shape and gluing them together ... TRADE SECRET Laminate a knee using marine epoxy More

Are you about to start fairing a hull? It may seem like a daunting task but there are ways of making the process run more smoothly – and achieve a great smooth finish. Before using fairing boards for final faring, why not try working with a grinding device? It will remove a substantial amount of material very ... TRADE SECRET: Top tips for easy sanding with WEST SYSTEM epoxy More

Would you like to protect your wooden boat from damage caused by the salt and moisture in the air? Brenda Priddy at eHow has posted a simple six-step process for sealing wood using WEST SYSTEM® epoxy. See what she had to say here: How to Seal Wood With West System Epoxy | eHow. More

Enavigo is a Croatian company from Virovitica specialised in building wooden boats using PRO-SET® epoxy. After completing two great projects, Enavigo Cutter and Enavigo K850, patience and persistence was crucial in the struggle with the economic crisis. But then, a new project suddenly came up – a challenge that the owner of Enavigo, Tomislav Matasić, couldn’t refuse… ... Building a composite racer in six months with marine epoxy: photo report More

Even without steam, wood can be remarkably flexible – and, indeed, just the job for installing a nice new teak cap rail on a yacht. This wooden boat repair can be a tricky process. Bending the wood can cause it to break or splinter at stress points. Luckily, Richard Toyne at Classic Boat has written some advice ... TRADE SECRET Wooden boat repair – how to install a new teak cap rail More

Stuart McGowan, despite his ties to the industry, only recently decided to leave his engineering job to pursue boat building. His enrolment in the Lyme Regis Boat Building Academy marks the start of this new career path. Who is Stuart McGowan? Stuart is a chartered mechanical engineer with years of experience in the water industry. ... How Stuart McGowan Changed His Career Path with WEST SYSTEM® Epoxy? More

How can you safely dispose of epoxy? Getting rid of PRO-SET® and WEST SYSTEM® Epoxy is straightforward if you follow these simple guidelines (and if you waste as little as possible in the first place…) How can you minimise epoxy waste? Not having to dispose of epoxy is easier than having to dispose of epoxy – ... How Can You Safely Dispose Of Epoxy? More

Nigel Chapman, a former engineer in the gas industry, found a fresh start in boat-building. After dedicating nearly 30 years to engineering, he decided it was time for a change. This led him to the Lyme Regis Boat Building Academy, where he is currently crafting a 12’ Fleet Trow using glued clinker construction. What Role ... Why Choose Lyme Regis Boat Building Academy for a Career Change? More

What’s So Special About the Solution60 Project? The Solution60 project is a remarkable venture led by Production Director Dave Skene of Solution Motor Cruisers. They’re building a 60ft powerboat, the Solution60. This ambitious project is the brainchild of Ray Davis and globally renowned yacht designer Bill Dixon. As Dave Skene puts it, “We’re building a ... How is the Solution60 Powerboat Changing the Future of Marine Construction? More

What Sparked Keith McIlwain’s Desire to Build ‘Daydream’? After a bout of ill health and a realisation that ‘you only live once,’ Keith McIlwain decided that he needed a change in his career. The Boat Building Academy in Lyme Regis provided Keith with the skills and confidence he needed to construct ‘Daydream,’ his 20’” Golant ... How Did Keith McIlwain Build His Dream Boat ‘Daydream’ with Epoxy? More

Hamish Cook, Technical Adviser at West System International, explains why two-step bonding should be your first choice for structural strength. Two-step bonding is a straightforward process. You wet out the surfaces you want to join using a mix of resin and hardener – that’s step one. Then you add filler to the mix and use this ... Five reasons why two-step bonding with marine epoxy creates a better joint More

If you suspect that a seam or rivet is leaking on your aluminium boat, try following the simple seven-stage process demonstrated in this video. It could have you back on the water within a couple of hours! All you’ll need is a heat source, a wire brush and an epoxy repair pack. Something like the WEST SYSTEM® 655-K ... Got a leak in your aluminium boat? It’s a quick fix with G/flex epoxy More

In this 8-page article on Sailing Today, our very own David Johnson shows that laminating using vacuum bagging is well within the reach of the reasonably skilled DIY’er. Starting with a second-hand laminated wooden centreboard from a Fireball dinghy, David uses the vacuum bagging process to create a strong rudder blade for a Swift 18. He ... Vacuum bagging made simple with WEST SYSTEM epoxy More

The chance to fix up a 7-tonne 1935 bermudan sloop designed by Dr T Harrison Butler doesn’t come around very often – only five are known to have survived. But, despite the fact that Mischief had been laid up for 20 years and required extensive work both inside and out, former design and technology teacher Roy ... Saving a 1935 Harrison Butler sloop with epoxy resin More

The components are assembled, the joint is bonded… what’s the next stage of your wooden boat repair? Before moving on to final finishing, don’t forget to apply a protective barrier coat to your wooden surfaces. Doing so will provide an effective moisture barrier and a smooth base for final finishing. Your WEST SYSTEM® Roller Covers ... Wooden boat repair: the basics of barrier coating More

Sometime after the fairing and shaping stage of you epoxy boat repair, but before final coating, it might be an idea to give the joints in your structure extra reinforcement and abrasion resistance by applying glass cloth. WEST SYSTEM® reinforcing fabrics are specially designed to do this and can be applied in multiple layers, or ‘laminated’ ... Epoxy boat repair: Protecting joints with reinforcing fabrics – it’s all in the layers More

Whether you’re using large amounts of epoxy or small, getting the right ratio of resin to hardener is vital to ensuring a proper cure. Though it is possible to dispense epoxy using weight or volume measures, you might find it easier and more convenient to use the specially-calibrated WEST SYSTEM® 303 special ratio Mini Pump ... Easy dispensing with WEST SYSTEM Mini Pumps More

Joe Latimer and Alex Lyddon have been working together to build their dream boat – now they are nearing completion, we catch up with them to find more out about the experience, and any problems they may have encountered along the way. Who are you? Joe: I’m a postgraduate ecology student at Exeter, originally from ... How Do You Build Your Dream Boat? – by Joe Latimer and Alex Lyddon More