Projects: Building a composite racer in six months with marine epoxy: photo report

Enavigo is a Croatian company from Virovitica specialised in building wooden boats using PRO-SET® epoxy. After completing two great projects, Enavigo Cutter and Enavigo K850, patience and persistence was crucial in the struggle with the economic crisis. But then, a new project suddenly came up – a challenge that the owner of Enavigo, Tomislav Matasić, couldn’t refuse…

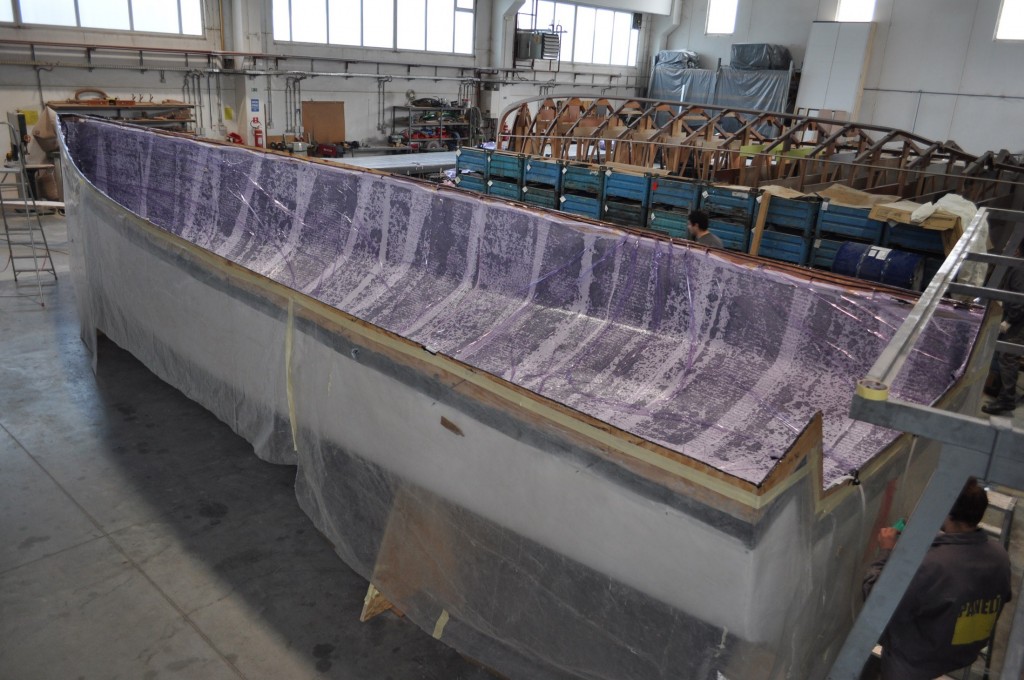

Here’s the racer in the early stages of construction. PRO-SET 125/226 epoxy and WEST SYSTEM 406 Colloidal Silica were used for the planking.

Faith or accident connected Tomislav with two legends: The Orsan, an old yacht club from Dubrovnik, and Slovenian designer Andrej Justin. The rest, as they say, was history.

The challenge? Building a new, fast, top-quality 38ft racer suitable for off-shore regattas. The deadline? Just six months away!

The designing and planning started almost simultaneously as the team set to work.

Here’s how the ultimate off-shore racer – dubbed the Enavigo 38 – was to shape up:

- Hull length: 11.6 m

- Hull width (max): 3.5 m

- Displacement: 3,765 t

- Keel: 1,850 t

- Sea gauge: 2.6 m

- Length at waterline: 11.53m

She would be high performance CFD and VPP optimised, heavy-duty built according to ISO 12 215 Category A (with FEA structural optimisation) and would include oversized equipment, where all the hardware was selected to MR standards.

During first test runs, the boat was in range of all planned speed parameters and risk factor 5 on most critical parts. The buyers were thrilled by the results and the Enavigo 38 Racer had arrived.

So exactly how did the team achieve this great result?

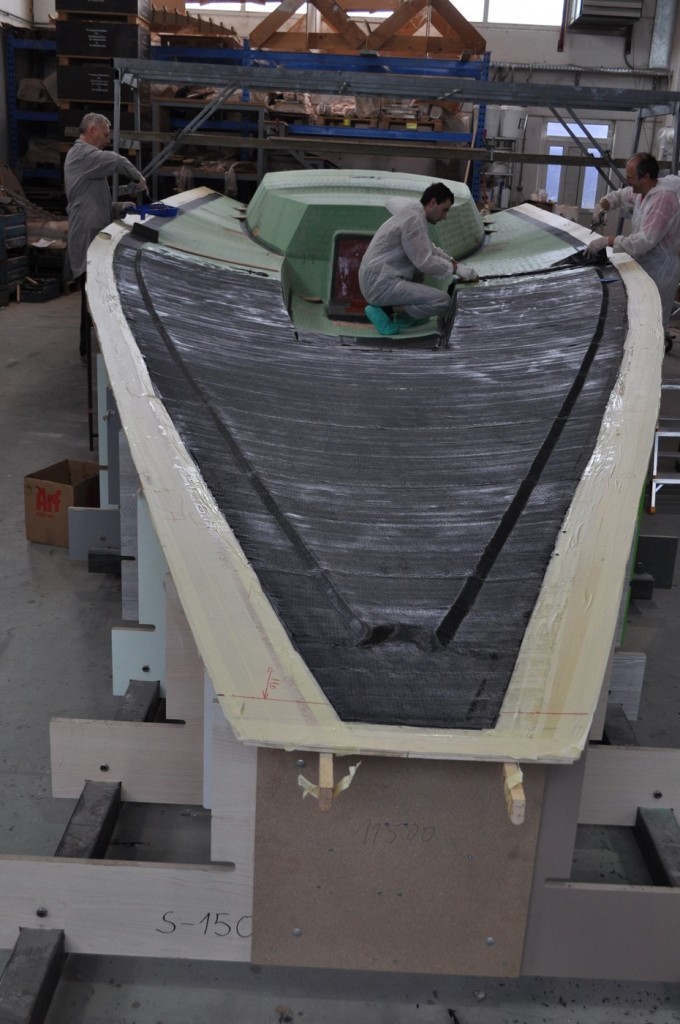

Hull and deck were built using carbon epoxy wet lay-up and vacuum bagging techniques. They were then post-cured in an oven.

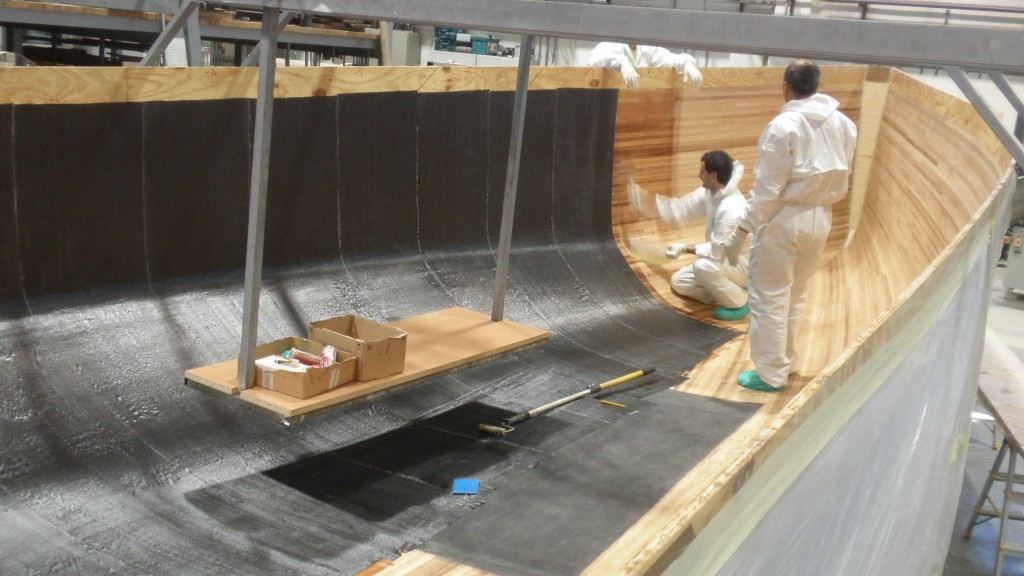

The hull is a sandwich construction consisting of carbon fibres and a western red cedar core, all laminated with marine epoxy utilizing in vacuum bagging techniques. The basic hull inner and outer skin laminate is ±30° and ±90° UD carbon.

For the red cedar planking, PRO SET 125/226 epoxy was used; for the carbon laminating, PRO SET 135/M2009 epoxy was used.

The deck was built using the sandwich construction method too. This time the reinforcement layers were carbon fibres and the core was PVC utilizing marine epoxy and vacuum bagging techniques. In addition local UD carbon reinforcements were employed as necessary.

As for the structural core of the racer, the chosen material was the lightweight wood (red cedar) of 15mm thickness.

The core material for the deck and structural elements is “Airex”. The core density (80-200 kg/m³) and thickness (10-25mm) are FEM optimised according to local construction loadings and core shear stress.

The helm of the Enavigo 38 Racer is very responsive, precise and a little bit stiff but it gives the helmsman great information and in high waves doesn’t “wiggle” a lot. She reaches speeds of over 9 knots and, at certain angles and wind power, can go faster than the wind.

When the wind abandons you, the 38 racer has a Yanmar with 20 HP and saildrive with a Gori racing propeller which is more than enough for solid speeds in no wind conditions.

The interior is pretty basic and simple but has lots of space for those longer regattas.

The Enavigo 38 Racer has participated in a few serious regattas already and the Orsan team is more than satisfied and proud.

We hope that we will see a lot of victories in the future, as soon as the team gets used to their new precious gem.

The final result! A 38ft racer, ready to take on all comers at the regatta. Not bad for six months’ work!