Projects: How Did I Become a Skipper Through Boat Restoration?

The journey began with a two-year work experience stint at Topsail Charters located in Maldon. This time served as an introduction to the intricate world of barges, where Sam Hicks was entrusted with the boats sailing and upkeep. “From there on I caught the bug of traditional boats and decided that was what I wanted to do as a career, a Skipper.”

While completing school and college, Sam volunteered on the barges during weekends to gain hands on knowledge.

Upon the completion of his studies, he was entrusted with a full-time role maintaining the barge and concurrently training to ascend to the position of a mate.

What opportunities emerged?

After a couple years, he was presented with the opportunity to work in conjunction with the lead shipwright, undertake a boatbuilding apprenticeship, and train for his skipper’s ticket. “In May of 2023, I took my BML and became one of the skippers of Hydrogen.“

What was Sam’s major project in 2019?

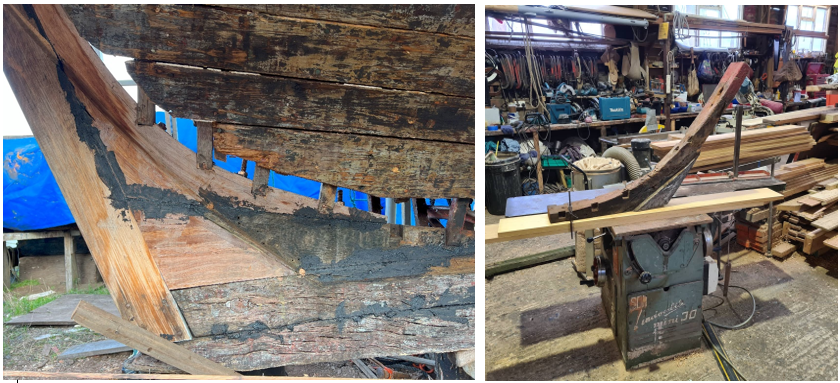

Back in 2019, Sam took on a project that was nothing short of monumental. He decided to breathe new life into a 1913 Harrison Butler named Fleetwing. Someone neglected this beauty and left it ashore in a yard for a staggering twenty years. “No one had laid a finger on her during all that time, leaving her in a pretty sorry state.”

Restoring Fleetwing was no walk in the park. It was a long, winding road filled with hurdles. But Sam, kept pushing forward, one step at a time.

When is the project expected to be completed?

When the boat was first acquired, he had a clear vision in mind: to re-plank her below the water line and refurbish a few frames. However, as he explored further into the project, he discovered it was more demanding than initially anticipated. Undeterred by the challenge, he dedicated 5 years into the restoration project. Finally, the cusp of completion is in sight, with just a few final touches remaining.

What materials and techniques were used in the restoration of Fleetwing?

“The material I used on Fleetwing was an Iroko planking which I had to scarf together in long enough planks to fit the sides. I used Oak for all the framing and the backbone of the boat.” He made a conscious choice to use WEST SYSTEM® 105 Epoxy Resin® in combination with the 205 Fast Hardener® and microfibres for all the gluing required. “I knew it would be a reliable way to hold the joints together.”

In the restoration of Fleetwing, Sam actively chose to use Iroko planking. Iroko’s durability and easy availability, particularly in light of the boat’s mooring in a mud berth, actively guided this decision. His choices reflect a practical approach, selecting materials that are not only accessible but also consider realities of the boat’s future environment.

What were the major setbacks in the boat’s restoration project?

Sam faced a significant setback during the restoration of Fleetwing. “The biggest setback I encountered was rotten structure when removing old planks.” This unforeseen issue necessitated the replacement of more planks and a complete redo of the backbone to make the boat sailable again.

Sam had to replace all the bolts throughout the structure due to the extent of the damage, as they had aged significantly and were becoming unreliable. Recognising the magnitude of the task, Sam realised, “it wasn’t a one-person job,” and sought help.

His crew for Gracie, another of his wooden boats, offered their assistance. Their interest in learning about wooden boat building and their invaluable involvement have been evident. Sam shares, “Since then we have been working together on Fleetwing making the process quicker and easier, as they’re an extra pair of hands for the tricky jobs I can’t do alone.”

Upon the successful restoration of Fleetwing’s lower half, Sam envisions a journey down the river and along the east coast. His crew, who were instrumental in the restoration process, will accompany him. They also plan to participate in old gaffer races. “In the future, I plan to restore her topsides, which will enable us to venture further afield.”

What are the future plans?

Looking towards the future for Fleetwing, he pictures a new hollow mast, “I will be using WEST SYSTEM® Epoxy to ensure it’s a good hold,” His plans also include a larger rig, with the creation of new sails and spars.

Once the restoration of Fleetwing reaches its completion, Sam’s attention will shift to Pelican, another wooden gaffer in his collection. Pelican, having suffered damage a few years ago, is in dire need of a comprehensive rebuild.

In addition to these projects, Sam has plans for Gracie, his 17-foot wooden day boat. “At some point this year, I will be hauling out Gracie to do some repairs on her stem and some paint touch-ups.”

What advice would you offer to other aspiring boat restorers?

Sam offers some candid advice for anyone considering a similar path. He says, “My advice for anyone looking into building or restoring boats is to accept there will be tough days and jobs you think you will not be able to achieve.” He emphasises the importance of teamwork, stating, “Having the extra person to call on for help is very reassuring as some jobs just need two people.”

When asked about what keeps him motivated, Sam shares, “To keep me motivated I think of the end goal and what I plan on doing with Fleetwing. I push myself to complete the jobs regardless of how much time they will take, knowing that it will be worth it in the end. Now that I am close to completing the Fleetwing project, I reflect on the experience. I can say that it’s a very rewarding job and every minute I’ve spent on it has been worth it.“

To follow more projects for Sam, find his social media below:

Have you subscribed to our FREE monthly newsletter? Sign up here!

Working on a project? Share it with us! Click here…