News: Ocracoke 20-B

Tell us a bit about your background and what motivated/inspired you to boatbuilding?

My business primarily focuses on agriculture, food, and related machinery sectors. I serve as an importer and distributor in Türkiye, representing seven different companies. I source high-quality seeds and machinery from reputable suppliers in the Netherlands, UK, Belgium, France, Germany, Finland, and Canada. Despite this, sports have always played a significant role in my life. Since 1992, I have been an avid windsurfer, participating in numerous competitions under the PWA World Wind Surfing Tour and IFCA International Funboard Class Association. It was during these events that I had the opportunity to become acquainted with WEST SYSTEM® Epoxy, which I would later use to build Ocracoke 20-B.

I was the only person who could carry out epoxy-based repairs for carbon boards in Alaçatı, Çeşme – a cherished local destination. While Alaçatı is well-known for its popularity among windsurfing and kitesurfing enthusiasts, it has recently gained recognition for its exciting fishing tours and highly anticipated Tuna tournaments, further amplifying its popularity. In recent years, my passion for fishing has gradually surpassed my interest in windsurfing, becoming my core focus.

How do I choose the right boat design for my custom Carolina boat project?

We had a large boat equipped with double engines that served our fishing team, but I began to realise the necessity of having something smaller, more suitable for everyday use with my son. I began exploring the market for alternatives. However, the prices turned out to be exorbitant due to high taxes and currency rates, and the local small boats didn’t meet our requirements.

Determined to find a solution, I embarked on the idea of building a small custom Carolina boat with a single engine. Because of my hands-on experience working with epoxy and fibreglass in the context of windsurfing equipment, I found it viable to explore the option of purchasing a plan. I then decided to undertake the construction process myself. After months of diligent research into designers, I finally made the decision to buy a plan from Alan Stewart and Graham Byrnes. They are the reputable designers at B&B Yacht Designs.

What projects have you been working on?

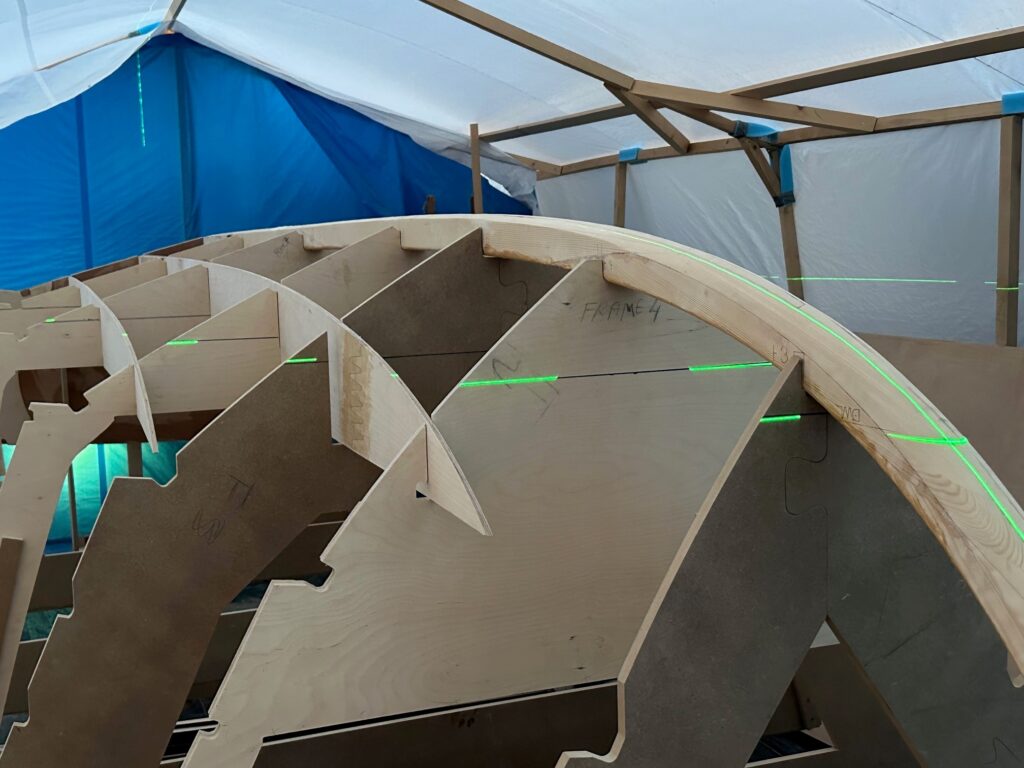

I am currently working on Ocracoke 20-B, a custom Carolina sport fishing boat with an integrated bracket for the outboard engine. With its sleek design and distinctive bow flare, this boat truly stands out. I started by cutting all the required components during the winter months, within a workshop based in Istanbul. This allowed me to bring this exciting project to fruition. After completing the cutting process, I transported the pieces to our summer house. There, I set up a tent as a makeshift workshop for the boat assembly.

Starting at the end of April, I diligently began working on the bottom planking, despite my occasional travel obligations for work. Thankfully, I have managed to carve out enough time to make progress on the boat. With all the pieces prepared and the bottom planking underway I am optimistic that the boat will be ready to hit the water by the end of August, provided everything goes according to plan.

What materials and tools did you use to create your project and why did you use them?

I’m using Okume plywood that has been cut with a CNC machine, as recommended by the designer. Additionally, I’m using medium density wood for the keel and chine battens. To bond these materials together, I’ve opted for WEST SYSTEM 105 Epoxy Resin® with the WEST SYSTEM 206 Slow Hardener®. Since the temperature exceeds 20°C, the slow hardener allows me to have more time to work with the epoxy.

I estimated that I would need around 50-60kg of epoxy for my project. To ensure I had enough for the entire endeavour, I decided to purchase the C pack. Additionally, I acquired the 301 pumps to make the epoxy application process more efficient. With these pumps, I can dispense the epoxy rapidly and effortlessly, providing me with enhanced flexibility and convenience.

In order to achieve strong bonding, I mixed the epoxy with WEST SYSTEM® 403 Microfibres. In areas that require added structural integrity, such as the transom, bracket, and keel, I incorporate WEST SYSTEM® 406 Colloidal Silica. Then, to expedite the bonding process, I rely on WEST SYSTEM 205 Fast Hardener®.

Were there any unexpected challenges or setbacks during the making process?

Of course, this presented a significant challenge for me. While I had experience working with fibreglass and epoxy on small windsurf boards, I had never built a boat before. Many people advised me to start with something small, like a skiff or a canoe. However, those options seemed impractical because we often encounter rough waters. I needed a vessel that could withstand the strong currents and waves. It was clear that I had to tackle something more substantial. I was confident in my skills, but this project took it to another level since I was now working with much larger pieces.

In contrast to my previous undertakings that were mostly spontaneous, I have been approaching this project with meticulous planning. Rather than relying on my own improvisation, my goal is to follow instructions precisely, ensuring a reliable outcome. I am adhering to the designer’s suggestions, and so far, everything is progressing according to plan. I initiated the planning process for this boat in November, dedicating a considerable amount of time to watching numerous boat building and woodworking videos on YouTube.

Do you have any other exciting upcoming projects you are planning to work on in the future?

One of my friends recently saw my project, the Ocracoke 20-B, and was intrigued by it. They expressed their interest in building a 28-foot Carolina flare boat next winter. However, they suggested that we wait to see the results of my first project before moving forward with the larger boat. This hobby of ours has the potential to evolve into a business here in Turkey. It’s important to note that Carolina flare boats are not commonly found in this region, and there are currently no specialised boat constructors who focus on this particular design. Despite the presence of a well-developed boat and yachting industry here, there is a gap in the market for smaller yet exquisite Carolina flare boats.

What advice would you give to anyone else looking to build/restore a boat?

Working on boat building or restoration requires patience as a fundamental quality. It’s crucial to remember that there is a solution for every challenge that may arise. One valuable piece of advice is to explore the vast resources available on YouTube, where thousands of techniques and approaches can be found. Avoid the temptation to improvise. Instead, stick to a well-planned method to minimise the risk of errors. Keep in mind that seemingly simple tasks can often consume hours, but the key lies in executing them correctly. Don’t rush; take your time. When fatigue sets in, it’s advisable to take a break and engage in something different before returning to work.

Click the icon below to access Koray’s Instagram: