Epoxy Basics: A Guide to Epoxy Bonding

The robustness of the epoxy doesn’t solely determine the effectiveness of bonding, fairing, or fabric application. Its ability to adhere well to the applied surface also matters. If you’re bonding the epoxy to a partially cured surface, the strength of the bond depends on the epoxy’s mechanical ability to grip the surface.

For the best results, follow these 3 steps when preparing your surface:

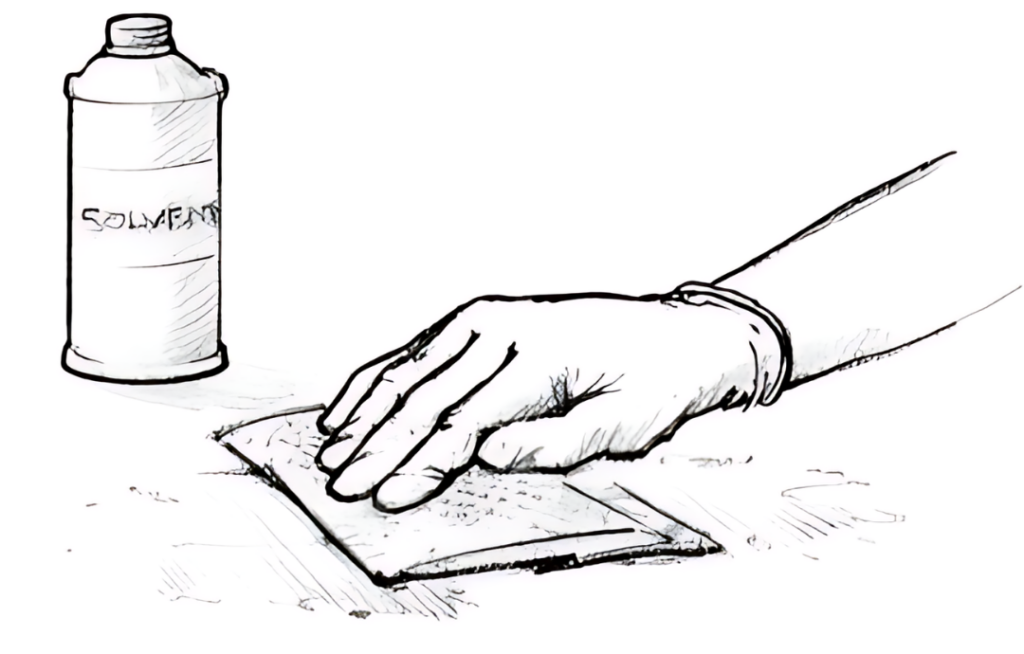

Clean it!

Remove any unwanted substances such as grease, oil, wax, or mould release. A good cleaning agent is the WEST SYSTEM® 850 Cleaning Solvent. Use fresh paper towels to wipe the surface before the solvent evaporates. Always clean before sanding to prevent the unwanted substances from being ground into the surface. Safety first when using solvents.

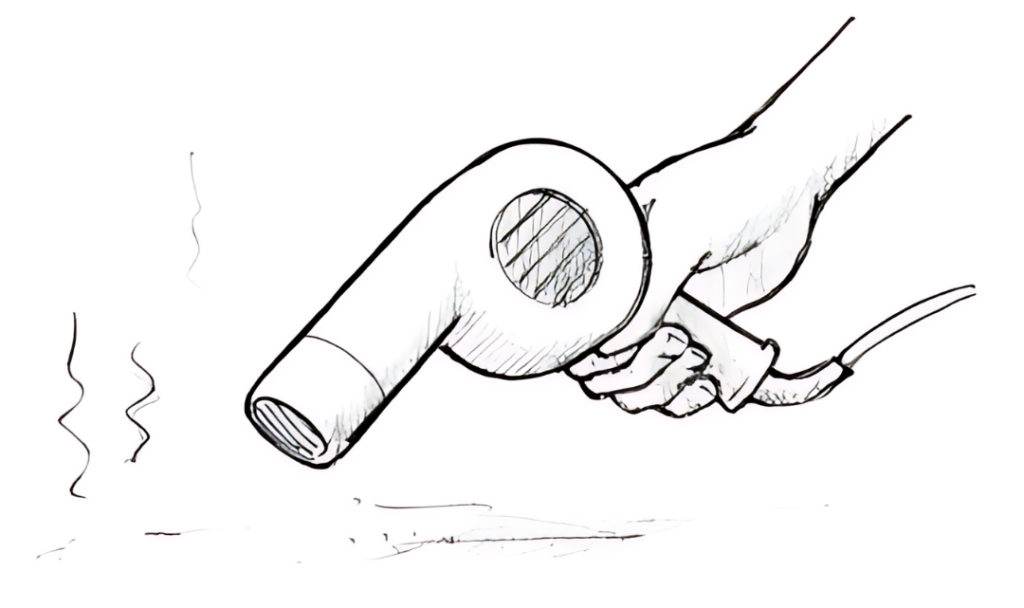

Dry it!

Make sure all surfaces are as dry as can be for the best stickiness. If needed, use tools like a hot air gun, hair dryer, or heat lamp to speed up the drying process. In tight or enclosed spaces, fans can help move the air around. Be mindful of potential condensation when working in changing temperatures.

Sand it!

To provide a good grip for the epoxy, use 80-grit aluminium oxide paper to thoroughly roughen up hardwoods and non-porous surfaces. Check that the surface to be bonded is solid. Get rid of any flaking, chalking, blistering, or old coating before you start sanding. Don’t forget to remove all dust after sanding.

What is the Difference Between Primary and Secondary Bonding in Adhesives?

Primary Bonding: This is when adhesive layers, such as those in a fibreglass laminate mould, chemically connect. All the layers cure together to create one unified layer. If you put epoxy on top of epoxy that’s still curing, they’ll chemically bond. This is what we call a primary (intramolecular) bond. But as the first layer of epoxy continues to cure, its ability to chemically bond decreases, and the bond starts to become a secondary (intermolecular) bond.

Secondary Bonding: During secondary bonding, an adhesive physically connects to a material or a surface that’s already cured, without relying on chemical bonding. Secondary bonds are weaker than primary bonds and are broadly classified as Van der Waals forces and hydrogen bonds. Preparing the surface properly (e.g. removing contaminants and abrading to increase the surface area / provide an opportunity for mechanical keying) helps to make it easier for the cured epoxy to connect to the surface.

How to Prepare Different Materials for Epoxy Application?

Cured Epoxy: A substance similar to wax, known as Amine blush, can appear on surfaces where epoxy has cured. The curing process produces this substance as a side effect. You can eliminate it by scrubbing the surface with clean water and an abrasive pad. If the epoxy stays sticky (which indicates it hasn’t fully cured), you can stick or coat it with more epoxy without washing or sanding.

Hardwoods: Sand the surface thoroughly with 80-grit paper before you apply any coating, and make sure to remove all dust.

Teak/Oily Woods: Clean the surface with a solvent, sand it with 80-grit paper, remove the sanding dust, and then clean the sanded surface with the solvent once more. The epoxy should be applied within 15 minutes of the final solvent wipe.

Porous Woods: Special preparation is not required. You should aim to sand the surface with medium-grit paper to expose the pores and remove any dust.

Metals: For metals, you need to degrease them, sand them with coarse paper or grit blast them, and then degrease them once more. Apply the epoxy immediately after you have prepared the surface.

Polyester/GRP: Remove any contamination with a solvent, sand the surface to a dull finish with 80-grit paper, and remove all dust.

Ferrocement: All previous paints and coatings should be removed by wet sand blasting. If rust from the reinforcing wires is visible, clean the surface with a diluted solution of hydrochloric acid, rinse thoroughly with water, and allow to dry completely before applying any coating.

Concrete: Remove all previous coatings and abrade the surface with a stiff wire brush. Make sure to remove all dust and debris before you apply any coating.

Plastic: The level of adhesion can vary. Hard, rigid plastics tend to adhere better with proper surface preparation and sufficient bonding area. After sanding, flame oxidising can enhance bonding in some plastics.

If you’re working with a plastic or any other material and you’re not sure about it, it’s smart to do a test to see how well things stick to it. We call this an adhesion test. If you’re using plastic, WEST SYSTEM G/flex® Epoxy can give you the best results. This approach ensures the material’s compatibility and enhances the overall result.

Don’t know where to buy WEST SYSTEM products? Find your local stockist here.

Have you subscribed to our FREE monthly newsletter? Sign up here!

Working on a project? Share it with us! Click here…