Amateur: Why boats are only the beginning for epoxy resin

The strength, resilience and flexibility of epoxy resin mean it’s perfect for everything from crossbows to cracked hosepipes, says Hamish Cook, Technical Advisor at West System International.

For over fifty years our heritage has been in boat building, using epoxy resin to transform the way that everything from wooden canoes to fibreglass yachts are built and repaired.

But the more time I spend working with it, the more I realise that marine use is really only the beginning for epoxy. The characteristics that make it so useful in the water are just as valuable on dry land too.

Take moisture resistance, for example. The advantages of that for boat building should be fairly obvious but that same impenetrability also means epoxy can be invaluable around the home. I’ve used it to repair and coat doorframes and window frames. I’ve used it to bond areas of garden decking together when it wasn’t practical to do so using a screw.

A colleague has even used epoxy to repair a fence post that was rotten at the bottom. By using WEST SYSTEM® epoxy, he was able to rebuild the post from the foundation, rather than replacing it.

Quick fixes, from pictures to hosepipes

Epoxy can also take the hassle out of simple household tasks. If you drill a hole for a picture that ends up being too big for the rawlplug, simply squirt a little epoxy in the hole and the rawlplug will hold fast. Not only that, but the strength of epoxy means you can rely on it to hold a very heavy picture.

That strength was the reason I used epoxy recently to attach timber inserts around my window lintels before attaching curtain rails to them.

Its reliability (along with the money I would save) was at the front of my mind when I used it to fix a cracked hosepipe, rather than replacing it.

Perfect for hobbyists

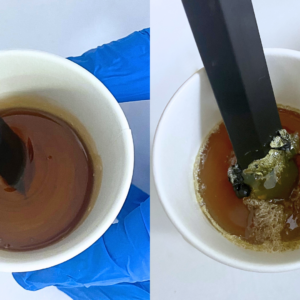

Away from DIY, I’m also building an archery bow from a bamboo flooring plank. I’ve used WEST SYSTEM G/flex Epoxy to bond together a finger joint in the bow and to reinforce it front and back, because I know the strength it has, even when flexed, means the bow won’t snap or become brittle when I’m pulling it to its full extent.

I know many model aircraft builders who rely on epoxy too, because it’s strong but light. I’ve seen it used to bond everything from balsa wood aeroplane frames to massive models with 4m wingspans and working jet engines.

Choosing WEST SYSTEM products

If you’re wondering where to start using WEST SYSTEM products for non-marine tasks, I’d recommend investing in WEST SYSTEM G5 Adhesive – our quick-curing ‘five minute epoxy’ – and WEST SYSTEM Six10 Thickened Epoxy Adhesive – which comes in a self-metering coaxial cartridge.

We’ll look at how these and other products can be used in all kinds of ways around the home and for hobbies in the coming months, as we feature more content on epoxycraft that looks at non-marine epoxy use.

If you’ve got subjects you’d like covered – or if you’ve used epoxy in an innovative way – we’d love to hear about it.

I sometimes think there’s an endless number of uses for our products but we’ll never know what they are because nobody has a brain big enough to think of them. It’ll be interesting to see how many we can come up with together…

To let us know your ideas for future blogs or to tell us how you’re using epoxy off the water, get in touch.

Image credit: https://rautaportti.fi/cross-_and_longbows/traditional_wooden_crossbow