Epoxy Basics: What is an Exotherm?

Our technical staff member, Hamish Cook, has been answering various questions about epoxy. This week, we posed a question to him: ‘What exactly is an exotherm?’ Let me share with you his insightful response…

Exotherm refers to the heat produced because of the interaction between a resin and hardener. The chemical reaction between the epoxy resin and hardener is exothermic, meaning it releases heat. The exothermic heat will increase when larger amounts of epoxy are mixed, or when the mixture is kept in bulk. This explains why the pot life is shorter than the gel time and open time (when the epoxy is spread thinly). Distributing the mixed epoxy over a wider area helps in the dissipation of heat.

When you’re working on a project, there are two important timeframes to keep in mind. First, there’s the ‘open time’. This is the time you mix your materials, apply them, smooth them out, put everything together, and get it all clamped down.

Then, there’s the ‘cure time’. This is how long you must wait before you can take off the clamps, do some sanding, or move on to the next part of your project.

What determines these times? Well, four things. One, the speed. Two, the temperature of your epoxy. And three, how much epoxy you mix. And four the shape and size of the container the epoxy is in.

Hardener Speed

Each hardener works best at a certain temperature. The same curing steps occur for all resin and hardener mixes, but the speed of curing changes.

It is advisable to opt for a hardener that offers an ample duration of usability for the task. This is considering the existing temperature and conditions. Detailed information about the pot life and curing times of the hardeners can be found in the ‘Product Guide’, which will facilitate the efficient completion of the work.

What is ‘Pot Life’?

The term ‘pot life’ is utilised to differentiate the curing rates of different hardeners. It denotes the time span during which a specific quantity of mixed resin and hardener retains its liquid form at a particular temperature. For example, we often test a 100g mix of epoxy in a standard container at 25°C to see how long it stays liquid.

Because pot life is how quickly a certain amount of epoxy hardens; It’s not about a thin layer, but a mass of epoxy. So, the pot life of a mix of resin and hardener is shorter than its open time, which is how long it stays workable when spread out.

How Does Temperature Affect the Curing Process of Epoxy?

The curing speed of an epoxy mixture is directly influenced by the surrounding temperature. This is a combination of the ambient temperature, which is the temperature of the air or material in contact with the epoxy, and the exothermic heat produced by the chemical reaction.

As the ambient temperature rises, the epoxy’s curing process accelerates. In essence, a warmer environment leads to quicker curing of the epoxy.

The Volume of Mixed Epoxy

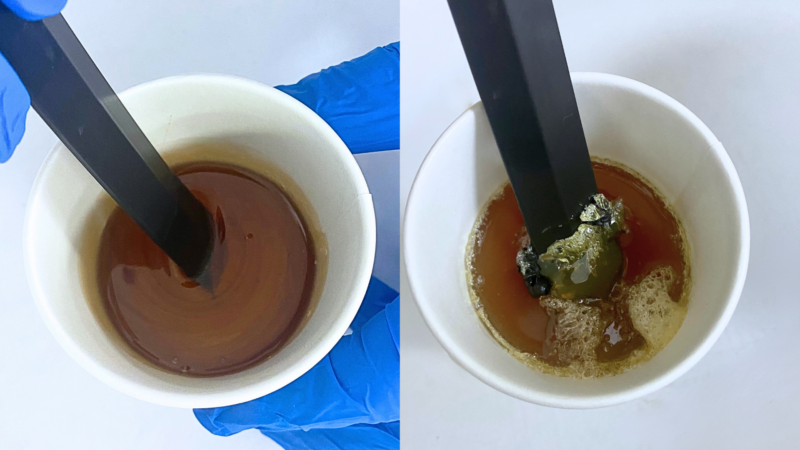

When you combine resin and hardener, it triggers a heat-releasing, exothermic, reaction. It’s advisable to prepare epoxy in small quantities. This is because the larger the batch, the more heat it produces, which in turn shortens both the pot life and cure time.

For instance, consider a plastic mixing cup with a 100g mix. The heat generated in a larger volume like this can be intense enough to melt the cup. However, if you spread the same amount thinly, the heat doesn’t build up as quickly. Consequently, the ambient temperature becomes the primary factor determining the epoxy’s cure time. This way, you can manage the exothermic reaction and prevent any unwanted incidents.

Have you subscribed to our FREE monthly newsletter? Sign up here!

Working on a project? Share it with us! Click here…