Trade Secrets: Why Choose Pre-Mixed Adhesive for Quick and Quality Results?

If you need strength and adhesion in a hurry, or if you’re worried about mixing epoxy accurately or don’t have the right tools to hand, WEST SYSTEM® Six10® pre-mixed adhesive could be the trade secret you’re looking for.

What Makes Six10 a Perfect Choice for Various Applications?

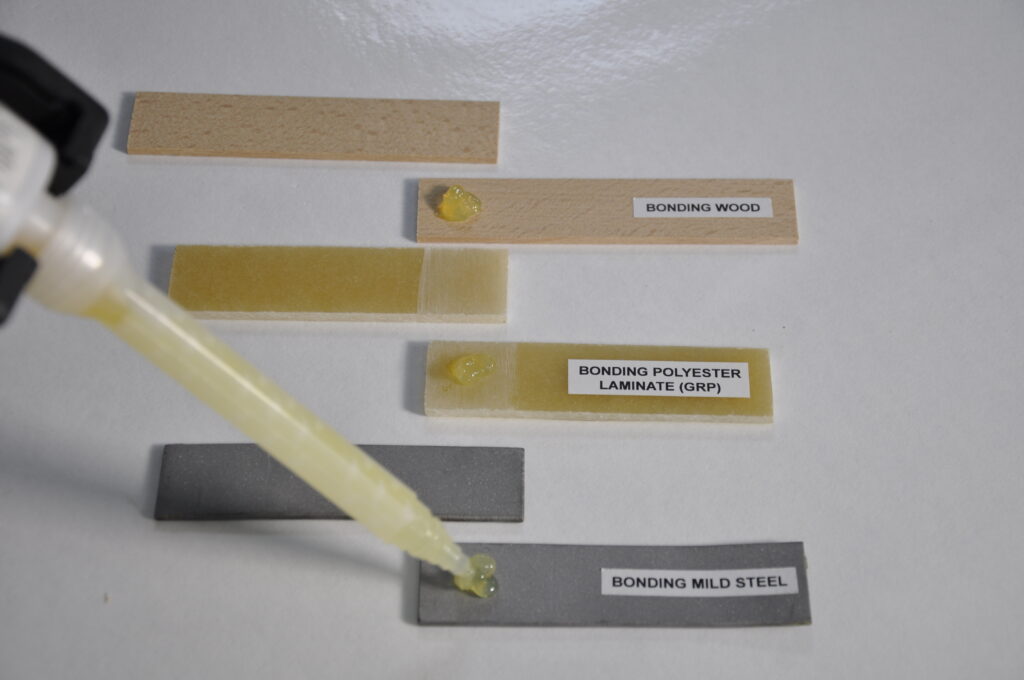

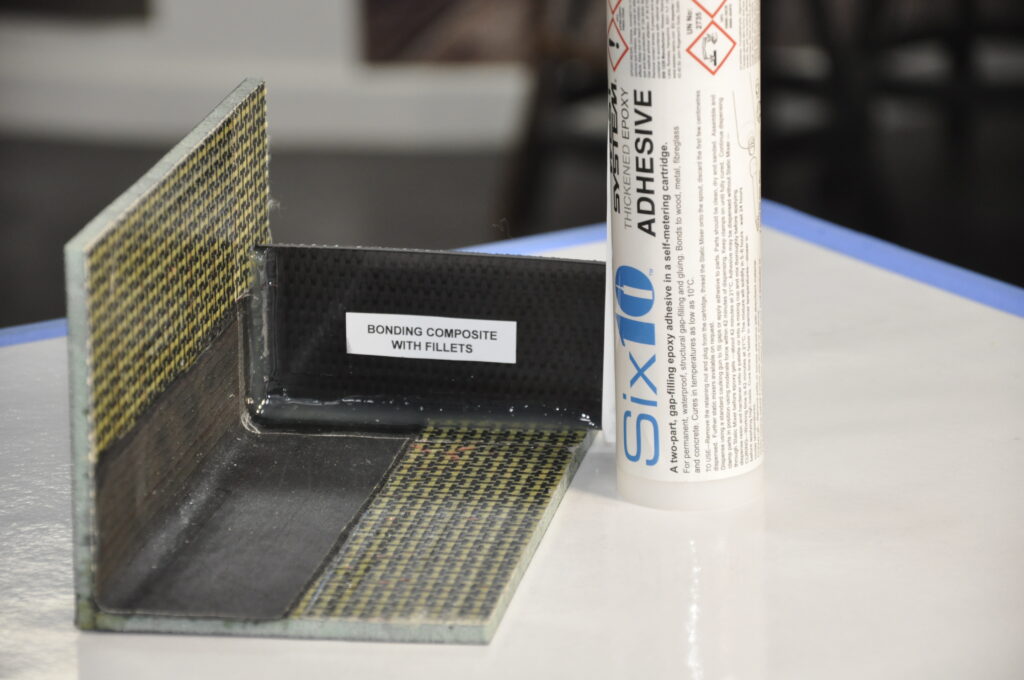

Six10 is a two-part, pre-thickened epoxy adhesive, perfect for stitch-and-glue boat construction, fibreglass laminate repair and general bonding. It balances the toughness of G/flex® with the strength and stiffness of our WEST SYSTEM Epoxy, allowing you to use it on wood, metals, and composites.

Why Trust the Quality of Pre-Mixed WEST SYSTEM Products?

And while we know some people are apprehensive about using pre-mixed, we also know the WEST SYSTEM name on any product guarantees quality you can rely on. Here’s why Six10 is well worth a place in your workshop:

How Does Six10 Save Your Time?

Six10 is provided with a specially designed cartridge that separates the resin and hardener for long-term storage. It also comes with a static mixer that accurately distributes a resin-hardener mix at a ratio of 2:1, and ensures that the resin and hardener stay separate until they are outside the cartridge. So you can spend less time preparing and more time working.

How is Six10 Powerful and Easy to Use?

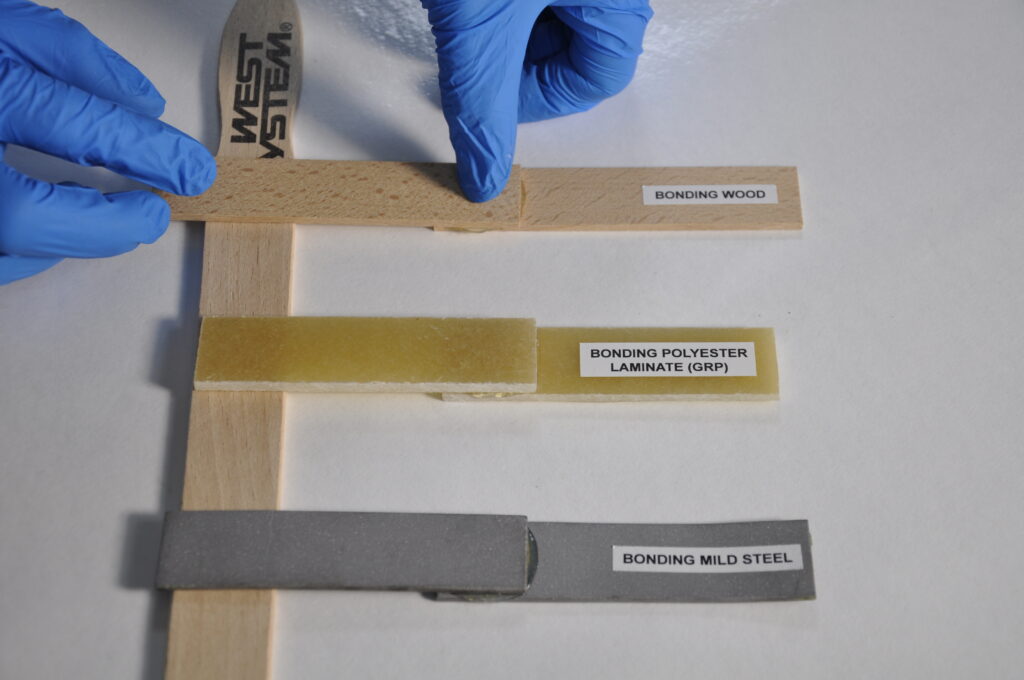

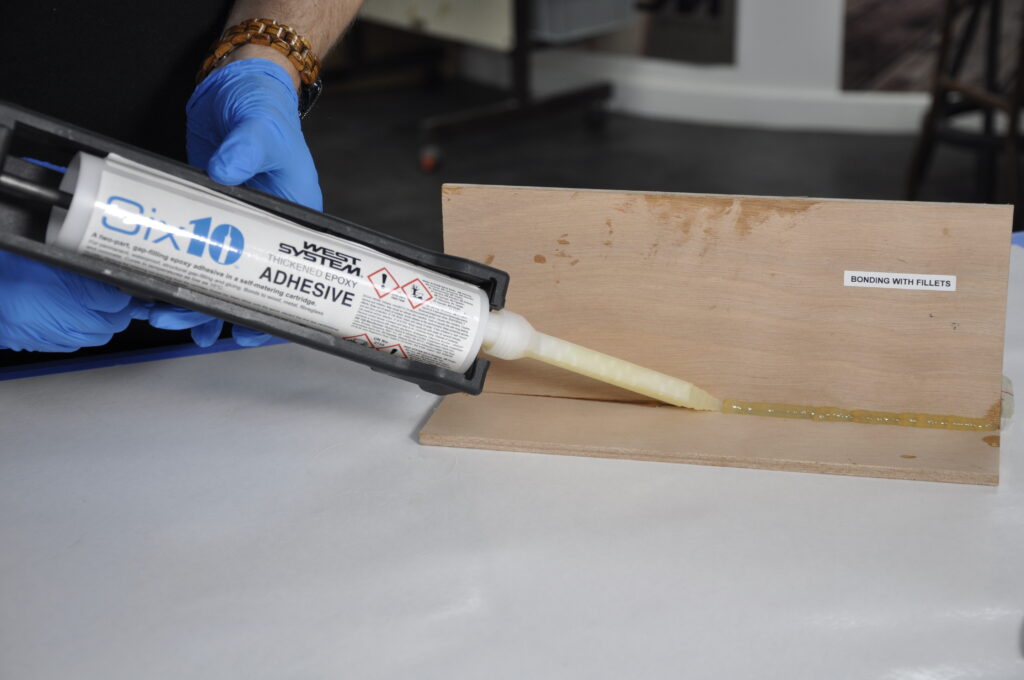

Six10 is shear thinning. This implies that applying a shear force – such as from a roller or the pressure of a caulker gun – makes it thinner, and then it thickens again once cured. And the advantages of that for you? It means it’s easy to dispense a bead of epoxy exactly where you want it using the static mixer provided. And it means you can easily work Six10 into a strong fillet that won’t sag once it’s cured.

How Does Six10 Provide Workability and Fast Cure?

You will find Six10 ideal for long or complicated assemblies, as it remains workable in the static mixer for 42 minutes and provides more than an hour of working time when used in a thin film. Then once you’re happy and it’s in place, it acts fast – with an initial cure that takes between five and six hours.

Why is Six10 Ideal for Wetting Out Substrates?

The filler used in both the resin and hardener components of Six10 makes the product ideal to saturate and wet-out light/moderate-weight surfaces like fibreglass and carbon fibre without pre-coating. In fact, using a stiff plastic spreader, you can wet out any fibreglass fabric lighter than 12oz per square yard.

How is Six10 Compatible with Other WEST SYSTEM Products?

We designed Six10 to work perfectly with all other WEST SYSTEM products, so you can apply it on top of or underneath our 105 Epoxy Resin, whether it’s cured or uncured.

How Does Six10 Combine the Strengths of 105 and G/flex?

Our chemists developed WEST SYSTEM Six10 to bring together the strength of our 105 resin based epoxy and the toughness of G/flex. It has a modulus slightly lower than 105 resin based epoxy, making it suitable for adhesive applications where you might use a filled WESTS SYSTEM epoxy mix. You can also use it to create laminates that are closer to a 105 resin-based epoxy laminate than the more malleable G/flex laminate.

Have you subscribed to our FREE monthly newsletter? Sign up here!

Working on a project? Share it with us! Click here…