Projects: The race-winning Exocet: built to sail faster for longer

Take decades of boat-building knowledge, add one renowned Moth designer and a handful of the UK’s elite Moth sailors, then apply some PRO-SET® epoxy to the mix. What do you get? Exocet: the race-winning, high-performance and ultra-controllable International Moth produced by master boatbuilder Simon Maguire, owner of Hampshire-based Maguire Boats.

“I’ve always been excited by foiling,” says Simon. “Soon after I set up my company six years ago, I started playing around with the International Moth. Ultimately, you want to build a boat that’s faster than the competition. But it’s since adding foils that this development class has really taken off.”

‘Take off’ is an apt turn of phrase for a class which is designed and built to fly. The Exocet has been soaring through the finish line in races around the world of late, culminating in a hugely impressive string of podium places – first, second, third and fifth – at the 2016 Moth World Championships in Japan, which were held in Hayama from 23-29 May.

However, championships aren’t won by the fastest boats; they’re won by those who can sail faster for longer. This means minimising the time spent going slowly around the course – in other words, maximising the time on the foils.

“You see a lot of crafts out there foiling wildly. What makes the Exocet so special is that, while reaching top speeds, she remains very controllable,” explains Simon. “And that comes down to her build quality, stiffness and good design.”

The Exocet is the product of a collaboration between boatbuilder Simon, Moth designer Kevin Ellway of Aero-Hydrodynamic Design, plus some of the UK’s leading Moth sailors. In 2013, the first Exocet was born and it has been in development ever since. Innovation never sleeps in the Moth class and Team Exocet work continuously to make refinements to both hull and foil design, fine-tuning their creation to reach higher speeds and improve performance and ease of use.

“We’ve produced a boat whose hull, wings and foils are all very stiff and this translates into controllable speed.”

“Together, we’ve produced a boat whose hull, wings and foils are all very stiff and this translates into controllable speed,” explains Simon. “The Exocet foils very early and is easy to tack and gybe – even in strong winds. All of this means she’s easier to sail than the competition, so the guys can sail her faster for longer.”

Built for speed

That is certainly proving itself to be true. In addition to her success at the Moth Worlds, the Exocet placed first in the 2015 UK National Championships and Moth Europeans Lelystad. “In fact, she holds the outright UK Moth speed record of 31.07 knots,” smiles Simon of this hugely impressive accolade. So what does it take to build such a race-winning and controllable craft? For Simon and Team Exocet, PRO-SET products were an obvious part of the process.

“I’ve been building lightweight dinghies for many years and have been using PRO-SET products from the very beginning.”

“The epoxy laminating system is so important to the end result,” explains Simon. “If the epoxy system is inferior, it can ruin the robustness and integrity of the end result. I’ve been building lightweight dinghies for many years and have been using PRO-SET products from the very beginning.”

Simon and the team build the main body of the Exocet through wet lay-up in conjunction with vacuum bagging, using PRO-SET epoxy products – namely PRO-SET LAM-125 Resin® and PRO-SET LAM-226 Hardener®. Additionally, the team uses PRO-SET ADV 176/276 Toughened Epoxy Adhesive® for the critical bonding of high-load components, including the foils.

During the wet lay-up process, epoxy is applied by hand to the carbon fibre using a roller. The entire craft is then covered with a bag and vacuum pressure is applied to remove as much air as possible, before the structure is cured. “We find that this careful approach delivers the best results for the hulls and decks,” explains Simon.

Saving time with epoxy infusion

Recently, Simon has been working with David Johnson of West System International to explore the use of epoxy infusion to give the foils the stiffness they demand. “For thin struts the foils must take a lot of load, so we’ve sourced ultra high-modulus (UHM) carbon fibre which can be infused and we are literally just putting our first infused parts into production.”

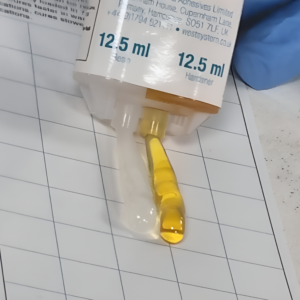

For the new infusion process, Simon is using PRO-SET INF Epoxy. As with laminating, the foils are vacuum bagged. Once as much air as possible is removed, Team Exocet prepares PRO-SET INF-114 Resin and Hardeners for infusion. The mixed epoxy is then piped into the bag, the pressure forcing the epoxy to distribute evenly.

The move towards epoxy infusion for the foils has required Simon and the team to change entire processes and equipment. So, has the investment been worth it? “Absolutely,” says Simon. ” We are infusing all our main foil verticals now. The shift has enabled us to create a virtually 100% pinhole-free surface finish and a foil with a much higher stiffness – ultimately a much better performing, more controllable and more robust product.

“In fact, apart from the great laminate quality, we can prep and spray a vertical in under an hour and in one hit,” he adds. “It used to take three hours. This is a great time saver.”

Eyes on the prizes

Maguire Boats has just produced its fiftieth Exocet. The company has another 50 boats on back order and has just ramped up production to three moths every two months. So great is the demand for this high-performance craft, in fact, that the next available build slot isn’t until March 2020.

In the meantime, the Exocet has maintained its hot winning streak, at the Moth European Championships in Bordeaux, 18-24 June. With 19 Exocets attending, Maguire Boats dominated the leaderboard in spectacular fashion, securing first, second, third, fourth, fifth, sixth, seventh, eighth, tenth and eleventh. Let’s hope they can grab that elusive ninth spot next year!

To find out more about the Exocet, visit the Maguire Boats website and Facebook page.

Wondering if laminating or infusion epoxy is right for you? Explore the full range of PRO-SET products on the West System International website.