Projects: My Project: an 18ft classic powerboat by Simon Hawksley

From boat enthusiast to boat builder

When I was a kid, my dad used to take me to the seaside and we’d go out fishing on a tiny boat with a four-horse outboard motor. When I went to university to study engineering, I got involved with the scuba diving club and spent time around all kinds of boats, from small ribs, right up to 50+ foot motor boats. Later on in my career I worked in the oil and gas industry for a company with a fleet of very specialised ships.

Although I’ve always been around boats, I always dreamt of building one too. When I finally got the chance to enrol in a 38-week traditional boat building course at Lyme Regis Boat Building Academy, I jumped at it.

As well as training us in all the skills needed to build a boat, the course gave me the opportunity to build my own boat from scratch. I was initially planning to build a simple, traditional wooden boat, maybe with a single cylinder diesel engine. Then I had the good luck to see a Deep V 16 Inboard classic powerboat built by a previous student at the academy and I thought, “I want one”.

Based on feedback from the boat’s owner, I decided to make some modifications to the design for my own boat. Specifically, I decided to stretch the boat by two feet and use the extra space to extend the cockpit. I also decided to fit a stern-drive engine rather than a jetski engine, which turned out to be a good move.

The course was intense from the very beginning. We started by learning hand tool skills before mastering boat building machinery and wood and GRP repairs. There were new challenges every week, from learning how to make a dovetail joint, to laminating and steam-bending wood – which was a particular highlight for me. It really opened my eyes to what wood can do and the shapes you can make with it.

Getting started

After gaining the basic hand tool and machine skills I needed for the build, I ‘lofted’ my boat, creating full size construction plans elongating the original 1960s inspired powerboat design to 18’ to allow for the extended cockpit. The resulting design, which we called “Etoile 18”, has all the great features of the original design, including the original hull shape and transom shape – just a bit bigger.

Building with wood and epoxy

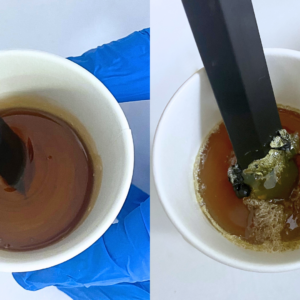

I built the boat using wood/epoxy construction techniques, mainly using WEST SYSTEM 105 resin® with WEST SYSTEM 205 Fast Hardener®. The first thing I did was build the Douglas Fir frames for the hull using halving joints with thickened epoxy. With the frame upside down, we built the keel and stem, which were Sapele laminated using ¾” and 3mm thicknesses respectively. I then planked the hull using WEST SYSTEM epoxy and three layers of 6mm Robbins Elite Marine ply. The construction was basically the same as cold moulding but with the frames left in – it’s officially called “plank on frame” construction.

After the three layers of ply, I put on two layers of biaxial glass cloth, laminated with PRO-SET epoxy using rollers. When it had cured, I washed off the amine blush and filled and faired the hull with WEST SYSTEM epoxy, thickened with a glass-micro-bubble filler that was easier to sand.

With the hull finished and turned over, I used WEST SYSTEM products for the entire interior fit-out and for laying down the deck. By this point, we were getting near launch date. There were some extremely long days and I remember I didn’t sleep at all on the eve of the launch. That night I still wasn’t sure if my Deep V 18 Inboard would be ready but it all came together at the last moment and I launched her on time.

Classic lines, 21st Century technology

All the fixtures and fittings on the Etoile 18 are classic, with no visible plastic. It also has a classic 1960s “Tumblehome” shape, where the hull comes out at the bow in front and then rolls over and comes in at the stern, with the transom forming almost a semi-circle shape at the back. It adds a touch of class and it’s a shape that’s very difficult to achieve with GRP, which marks it out as a custom classic wooden boat.

While the design is classic, the rest of the boat is bang up to date and modern, as well as providing all the comfort and convenience people want these days. The engine is also amazing – it’s a Mercury Marine MerCruiser 5.7 litre, V8 motor that offers great performance and sounds amazing. In the future, I’ll probably choose to fit V6s but I couldn’t resist a bonkers V8 for my own boat.

One unexpected benefit of the epoxy/wood construction is the sound of the V8 engine. It’s as if the wood resonates and transmits all the lovely engine noises, without any of the vibrations and rattles of GRP boats. It’s music to my ears.

Setting up for business

After finishing the build, I can’t wait to start building my next Deep V 18 Inboard. I’ve now set up a business – Hawksley Classics – to take commissions and we’ve just agreed a lease on a lovely workshop in the St Michael’s Estate, Bridport.

The goal is to build at least two boats in the next two years, which would allow me to employ more people and ramp up production. Having said that, Hawksley Classics will always be a bespoke yard where absolutely everything is customised for individual clients.

We’ll use whichever woods the client wants (as long as they’re fit for purpose) and we’ll also customise the cockpit and deck layout for them. We’re talking about fully bespoke classic powerboats that offer great performance, elegance, style and – of course – comfort too. If a client doesn’t say “Wow” when they see one of my boats, then I’ll have failed.

Find out more about the Etoile 18 and my new company at www.Hawksleyclassics.com

To learn more about the Boat Building Academy visit their website.

Find out more about the photographer, Jenny Steer on her website (https://jennysteer.co.uk/).

For the full range of WEST SYSTEM products, visit the West System International website.