Projects: Grey Falcon Update

David Grey is now in the engineering stages of his home build of a 5.8m barrel-back American-designed Glen-L runabout , but – as he laments on his blog – why does everything take so long? The timetable also took a knock when David had an accident with a bandsaw. A very slight misalignment with the teeth on the blade caused a piece of timber to jump up and make a mess of his fingers.

Thankfully David is now healed and back in action, so here is a brief summary of where this remarkable home build is now. Whilst the key build stages using WEST SYSTEM products have now largely been completed, we are sure Epoxycraft readers will enjoy how the boat is finally coming together.

November 2017:

The bottom of the hull was painted with six coats of primer, followed by seven coats of two-pack Jotun paint. This was allowed to cure and then polished for two days. Then it was time to roll the boat over.

“It has taken two years and five months from the start date, and I could not be happier,” David writes. “I am very pleased with how the interior looks. After some cleaning up and the washing off of amine blush, followed by a light sand and a coat of paint, it looks pretty good, but of course the next boat will look better. Nothing beats experience.”

May 2018:

David has finished sanding the interior, a process that he says took him three weeks but has made him the darling of Festool. He has chewed his way through around 250 of their sanding discs.

The interior has been coated with an epoxy-based paint from Jotun, and David is very pleased with the finish this formula produces.

“As with anything epoxy-based, the fumes are pretty horrendous, especially when it is being sprayed,” David advises.

The real challenge has been the engineering, most notably the second-hand gearbox. In trying to save money, David has sadly wasted a lot of time and energy and ended up with a bill not shy of buying a brand new mechanism. “Lesson of the month – what is cheap is dear,” he says.

July 2018

Just in case the followers of his blog thought he had been idle, David has published a long list of jobs he has been doing between his posts. Much of the woodwork has involved planning and sanding the chine and deck and installing the mahogany edging timbers.

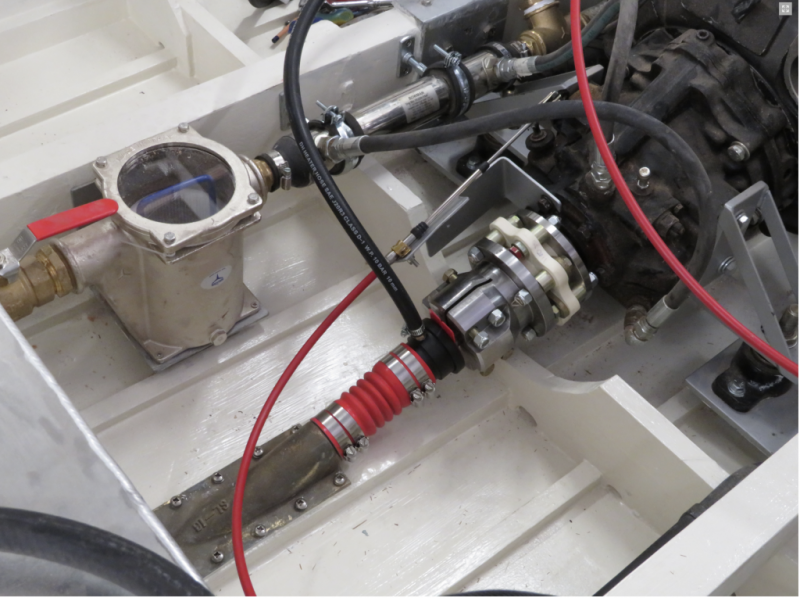

David has also installed the prop shaft and begun what will prove to be a long struggle with the engineering. WEST SYSTEM epoxy has been used to help seal the GRP prop shaft and the metal P bracket into position.

“Drilling the shaft hole was less difficult than anticipated,” he says, “especially if you line the hole with a GRP tube. That gave me some flexibility when it came to sealing it. Mix the epoxy fairly thick to stop it sagging, but make sure you coat the timber with unthickened epoxy first.”

August 2018

Taking a break from engineering, David is now back to the part he enjoys the most – woodworking. He has made up the sections for the foredeck, and also created the dashboard with a rough-cut ‘Zebrano’ timber veneer to go on top.

He has also taken the decision to beef up the floorboards, feeling that the 12mm specified in the plans wasn’t enough. They are now 25mm.

Unfortunately, the bandsaw accident put paid to any more work until September.

September 2018

With his fingers mended, David is back to the less fun, more frustrating part of the build, but he is certainly winning.

He has had a great deal of help from Lancing Marine in sourcing components to replace those that he thinks were miss-sold to him, mainly the exhaust manifolds. Meanwhile, the ancillaries such as the cast bronze rudder seal, hydraulic arm and rudder blade have gone in, along with one of the exhausts and the fuel tank.

“I have some upholsterers coming to have a look and give me some advice,” he says. “That is one area I am definitely not going to do myself.”

We’ve only scratched the surface here, but you can read the blow-by-blow account in David’s upbeat style and with some fascinating photos on his website: www.greyfalcon.info