Board Sports: Can You Apply Carbon Fibre To A Skateboard Deck?

Carbon Fibre Application Guide

This comprehensive guide will walk you through the process of applying carbon fibre to both sides of a skateboard deck. If you’re not familiar with how to cut carbon fibre, please refer to our guide on Cutting Carbon Fibre before proceeding.

Required Materials and Tools:

- Carbon fibre fabric (Available from various suppliers)

- Two-component Epoxy (with pumps) (Available from various suppliers)

- Release Film (Available from various suppliers)

- Breather Fabric (Available from various suppliers)

- Foam roller (Can be found at stores like Home Depot, Lowes)

- Thin Air Press, preferably the 20×70″ TAP kit

- Additional items: Masking tape, paper towels, disposable gloves, sharp utility knife, mixing stick and tray.

Step-by-Step Guide

We’ll be applying two layers of carbon fabric, one on each side of a PINCHed drop board. A future guide will cover the addition of a pre-preg layer. The deck should be sanded smooth (using 150 grit sandpaper) with no bumps or rough edges. The image below shows the prepared deck with all edges kept sharp and not rounded.

Before starting, ensure all your materials are pre-cut. This includes:

- 2 pieces of carbon fabric

- 2 layers of release fabric

- 2 layers of breather fabric

It’s crucial to have your epoxy, Thin Air Press, and masking tape ready to use when working with composites.

For this type of lamination, I’m using West System epoxy, which is a general-purpose epoxy. It consists of 105 resin and 206 hardener. The hardener starts to set in about 45 minutes, depending on the ambient temperature.

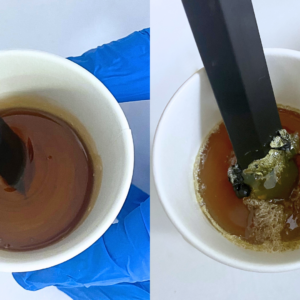

Epoxy heats up faster when it’s in a large mass compared to when it’s spread thinly, so it’s important to apply it to your project as quickly as possible. Accurate measurement of epoxy is crucial – too much hardener and it will heat up too quickly, too little and it won’t set properly. Using pumps can help measure the epoxy accurately. Initially, I used 8 pumps from each container and mixed them for about 60 seconds.

Apply an even layer of epoxy onto the bottom surface of your deck using the roller. I’ve added carbon powder to the epoxy to turn it black. This isn’t necessary but it helps to prevent the wood color from showing through the composite. However, it can dull the shiny look of the carbon fabric, so I don’t usually use it.

Place the carbon fibre fabric onto the epoxy-coated deck, keeping it as straight as possible along the length of the deck. It’s helpful to have an extra pair of hands for this step.

Flatten the carbon onto the deck and use the roller to remove any air bubbles from the material.

Apply an even coat of epoxy over the top of the deck, ensuring it’s completely wetted out.

Place a layer of release film onto the wet carbon fabric, keeping it straight.

Press the material down until it conforms to the shape of the deck. Use the roller to remove any air bubbles and straighten any wrinkles. It’s a good idea to wear rubber gloves for this step.

Place the breather fabric down and pat it down so it conforms to the deck surface.

Carefully flip the deck over, trying not to shift the carbon layer.

Apply an even coat of epoxy onto the entire deck.

Place the second piece of carbon fabric onto the wet deck.

Wet out the carbon fabric evenly with the roller.

Place the release film down and flatten it to the deck with the roller.

Pat it down flat.

Place the last layer of breather fabric down.

Use masking tape to secure pieces around the deck, taping every 6-8 inches. This will hold the loose material together when placing it in the TAP bag.

Place the deck into the TAP bag. One method is to fully open the bag by blowing air into it with a vacuum cleaner. While standing on a chair, carefully lower your project from above into the bag which another person holds open.

Keep your hands clean during this step. Avoid getting epoxy on the sealing tape or near the opening of the TAP bag as the sealing tape won’t stick properly if even a small amount of epoxy gets on it. Use plain white vinegar to clean your hands (not the bag), it removes epoxy really well!

Seal your TAP bag. Use the vacuum cleaner to remove the majority of the air then use the manual pump to remove the remaining air. Be sure to position the valve off the deck but over the breather fabric right beside the deck. This ensures that the air can escape but won’t leave a mark on the top of your smooth carbon area.

This is what it should look like once the air has been removed.

After a couple of minutes, check to see if the vacuum is still holding tightly. If any air has leaked in, check and re-press the sealing tape first.

The epoxy will start to harden in a couple of hours. Leave your project in the bag for at least 8 hours.

Removing the excess material

After removing your project from the TAP bag, you’ll need to peel away the release film and breather fabric. This requires a fair amount of pulling, and sometimes cutting along the edge of the deck.

Now it’s time to clean up the edges of the deck. A sharp utility knife works great. Be careful as the epoxy/carbon fabric is very sharp!

Trim as close to the edge of the deck as possible.

Use a file or coarse sandpaper with a sanding block to remove the remaining carbon to the edge of the deck.

It should look something like this when done.

On the bottom, I later added a pre-preg carbon layer. I made this by laminating it on a sheet of glass. A tutorial on this will follow soon.

That’s all there is to applying carbon fibre to a deck! Most of the work involves cutting the material and getting everything prepared.

By Ted from Roarockit – https://ministryofwood.com/how-to-apply-carbon-fiber/