Projects: Arbor 26: Where epoxy construction meets business excellence

Boatbuilder Jesse Loynes launched Arbor Yachts to create small luxury crafts that successfully combine speed and elegance. He put WEST SYSTEM® epoxy at the centre of his plans because it makes great business sense.

“I remember seeing a lot of smaller, 20-25ft classic yachts that reminded me of VW Campervans,” says boatbuilder Jesse Loynes, when asked what inspired his decision to set up Arbor Yachts back in 2012.

“The Campervans look fantastic and everyone waves when they pass you on the motorway, but when you’re actually driving the things you’re not having the best time.

“It’s the same with a lot of the smaller yachts: they look ever-so sweet, but you struggle to get them above four or five knots. I wanted to create something that was fabulous to look at, with a modern hull shape, exciting to use and easy to maintain. Using epoxy makes that far more feasible from a business point of view.”

The business benefits of epoxy

As Jesse sees it, there are numerous advantages to working with timber in combination with WEST SYSTEM Epoxy but he highlights three as being especially significant.

Firstly, there’s the flexibility it provides, both in terms of the sheer number of different uses epoxy has and in terms of the ability to change and customise boats without needing to build a new mould.

Secondly, there’s the resilience it ensures – and the fact that a boat created using epoxy will require less maintenance, as well as being lighter and potentially faster than the traditional wooden boat build.

Finally, there’s the aesthetic advantage. Epoxy coatings, after all, allow the natural warmth of wood to shine through. This was a major benefit for Jesse, who wanted to keep the elegance he felt was often missing from modern yacht designs.

The Boat Project: an inspiring process

Jesse first recognised this range of benefits, and began thinking about setting up Arbor Yachts, while working on an extraordinary marine artwork which involved creating a 30ft yacht from pieces of wood donated by the public.

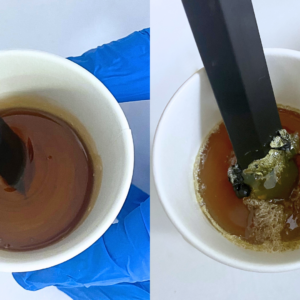

The project team for the Lone Twin Boat Project (http://www.theboatproject.com/) used various modern epoxy techniques, from sheathing the hull in glass cloth to bathing rotten pieces of timber in resin. Their creation was a sailing boat called Collective Spirit – a head-turning yet low-maintenance craft that was built to last.

The experience of creating Collective Spirit set Jesse thinking about what could happen next.

“We had the people, the contacts, we worked well together and we knew the techniques for things like building the hull, the decks and the internal structure,” says Jesse. “What I wanted to do was use those techniques to create a different sort of boat.”

“I wanted to create something that was fabulous to look at, with a modern hull shape, but also exciting to use and easy to maintain. Using epoxy makes that far more feasible from a business point-of-view.”

Arbor 26: fast but easy to maintain

That different sort of boat was the Arbor 26. The yacht is handcrafted with a western red cedar hull; its design, by Simon Rodgers, is developed for speed and takes its inspiration from Open 60s; it features teak decks, mahogany and maple veneers and is driven by a lightweight carbon rig. The attention to detail is enormous. Every joist, for example, is hand-filleted using epoxy.

Like Collective Spirit, the Arbor 26 is based on a strip plank core with a structural glass and epoxy skin inside and out, consolidated using vacuum bagging techniques. This provides strength and reduces the need for maintenance.

It’s also fast – capable of cruising at eight to nine knots, almost twice the speed of many boats its size. Using epoxy helped to create the light, sleek design that makes this possible – as well as helping to protect the craft.

Jesse says, “at this stage we had just put a layer of 300 gram glass cloth over the coach roof, using WEST SYSTEM® resin. The colour coming through from the timber, even with that cover, was pretty special.”

“Using epoxy means we’re not worried about osmosis so there’s no need for a gel coat over the top. That really comes into its own when we have timber on the outside, such as in the cockpit.

“It means if I happen to run around with gravel in my shoes and I’ll not damage the timber laminate or the veneer. It’s functional and it’s also aesthetically attractive.

“And in terms of maintenance,” he adds, “my big job on the Arbor 26 would just be to give it a polish and a UV seal every couple of years. Compare that to a traditional wooden yacht, which you need to paint and varnish every year and where it’s incredibly easy to scratch every surface.”

Customisable and eye-catching

When talking to potential buyers Jesse can highlight how straightforward it is to look after the boat. But the business benefits don’t end there.

There is, for example, the ability he has to customise his product. “One of the things I love about working in timber is that I can change things boat by boat,” he says. “If you build in GRP and you wish to develop the design, then you have to create a new mould. The latter option means you suddenly have a very substantial overhead cost.

“What’s more, because yachts such as mine are above all else luxury items, it makes great business sense to be able to offer my clients extensive customisation options. I’m talking to a potential buyer right now who wants more space below, so it’s easy for me to, for example, bring the bulkhead further aft to meet requirements such as these.”

There are also the aesthetic advantages that using epoxy provides. “Because it’s epoxy, I can leave the wood looking as though its uncovered,” says Jesse. “With most of the interior of the cabin area, we just leave a clear epoxy finish over the top of the wooden planking. It looks gorgeous and brings a lot more warmth and styling to the inside of the boat.”

Jesse Loynes can be contacted directly on hello@arboryachts.co.uk. To see how epoxy can benefit your business, explore the full range of WEST SYSTEM resin and hardeners.