Trade Secrets: TRADE SECRET: How to patch holes in aluminium boats with G/flex epoxy

At one time, discovering a large hole in your aluminium canoe may have meant admitting defeat with a trip down to the nearest recycling bin. But, with the rising popularity of epoxy products for boat repair, there is now a long-term solution that can means your boat can withstand further knocks and pressure – and can even help to camouflage the damage.

Using WEST SYSTEM® G/flex 650 epoxy, you can repair your damaged aluminium boat and restore its original functional and aesthetic quality. What’s more, the fairing mixture will smooth the outside of your boat and can even provide better scuff resistance on the inside.

Here’s how to get your aluminium boat back to looking shipshape.

Shape and clean the metal

First, get the hull back to its original shape by hammering out the torn aluminium or using an auto-body or bucking dolly (a US term). You can cut away torn edges to help the aluminium lie flat and, to reduce the chance of cracking, drill stopper holes at the end of each tear.

Then, soften the edges of the aluminium with 120 grit sandpaper and use a coarse bristle disc to remove paint, inside and outside, to create a sound bonding surface area. Finally, abrade the surface with 80 grit sandpaper. Now your surface is prepared for the repair.

Make the patch

To make your patches, cut a single piece of #743 280g/m2 Episize Glass Fabric for the outside and three pieces, in diminishing sizes, for the inside. Try to allow for two inches of overlap around the hole to give your materials space to bond.

Next, brush both surfaces of the canoe with the G/flex 650 epoxy, taking care to work the adhesives into the scratches and dings. A thickened mixture of 406 Colloidal Silica with the residual adhesive can help to fill any small holes and cutaways you may have around your repair.

To prepare the patches for bonding, lay the pieces on plastic and wet them thoroughly with the G/flex 650.

Apply the patch

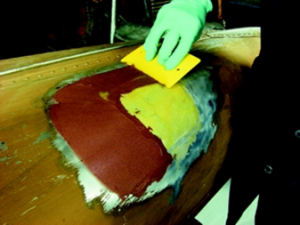

First, apply the single patch over the outside of the hole and smooth it into the thickened mixture. Next, stack up the three inner patches, squeegeeing them to make sure no air is trapped, and centre them over the hole on the inside. Once the stack of patches are in place, squeegee over the area lightly to remove any air.

When you are happy with the placement and shape of your repair, leave to cure overnight.

Fair the patch

The following day, ground the edges of the patches to remove any roughness and apply the mixture of G/flex 650 and 407 Low-Density Filler to fair the patches inside and out.

Finally, once the fairing mixture has cured, apply a mix of 503 Grey Pigment as the finishing touch to help camouflage your repair.

After letting your repair cure completely, you’ll be ready to test your canoe on the water!

For more information on using G/flex epoxy please visit: https://wessexresins.co.uk/west-system/west-system-g-flex-epoxy