Trade Secrets: Epoxy Tips – Priming The Pumps

PRIMING THE PUMPS

The Mini Pumps contain ball bearing valves and a spring for precision metering and quick return of the plunger. Note the extension tube insert at the very bottom of the pump.

The resin pumps simply drop into the containers via the filler cap and are screwed into place. The draw tubes are matched to the size of container, so they just clear the bottom. Make sure you have the pump set for the right pack so a 301B, for example, would fit a B pack of 105 epoxy resin and 205 Fast or 206 Slow hardener. (Your WEST SYSTEM epoxy supplier will be happy to advise about different pump sets).

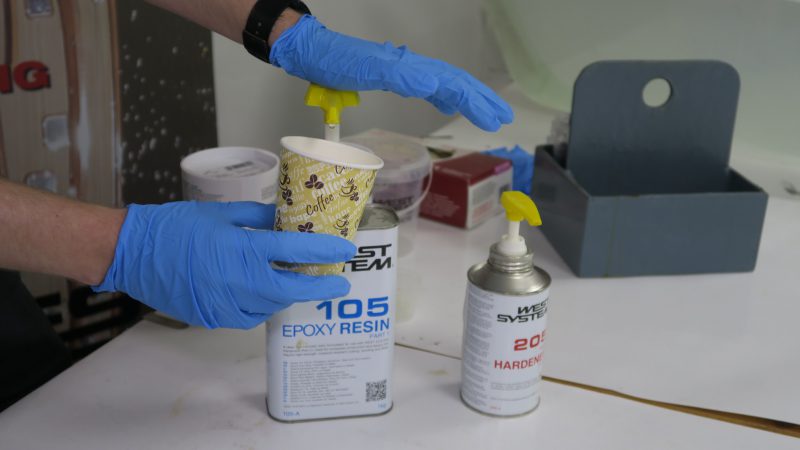

The pumps have ball bearing valves top and bottom, so to prime the pumps place a cup underneath the outlet and give a series of short ‘half pumps’ to tease the resin up into the dispensing tap. Once you see the first resin drops start to appear, catch them in a cup. The pump is now primed for measured strokes.

A series of short pumps will bring the resin to the tap. Catch the first drops in a cup.

You might find that in colder weather the pump recovery stroke is much slower, due to the thicker nature of the resin. Bringing the resin indoors before it is needed, or using a special ‘hot store’ is a good way to make the pumping easier for those winter projects.