How To: TRADE SECRET: Wooden boat repairs – replacing damaged plywood sections

Epoxy is the perfect solution to help with the common wooden boat repairs. Instead of replacing entire damaged plywood panels, damaged areas can now be cut out and bonded into place creating a strong and resilient wooden boat repair.

Boatbuilding with plywood and epoxy has become a popular choice in recent years. The simplicity of this method means that even a novice boat builder can produce strong and beautiful designs.

However, as with any method, there comes a time when repairs are needed. It may be that some dry rot has occurred due to damp weather, or perhaps the hull has just taken one too many knocks leaving a dent or even a hole.

At one time it may have been necessary to replace the whole panel – a process which can be costly and time consuming. But thanks to epoxy there’s another way. The damaged section can now be cut out and bonded into place without losing any of the panel’s strength.

The following four step process shows how it’s done.

1. Removing the damage

Using a circular or reciprocating saw, cut the smallest square or rectangle that encloses all of the damage out of the panel. Don’t forget to check the inside of the panel to make sure the full extent of the damage is removed.

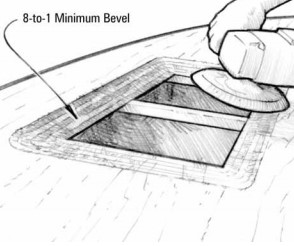

Next you’ll need to grind a scarf on the edges of the opening which will create a stronger bond. This can be done using a disc sander – sanding a minimum of an 8:1 bevel back from the edge of the opening (8 times the thickness of the wood).

2. Making the replacement panel

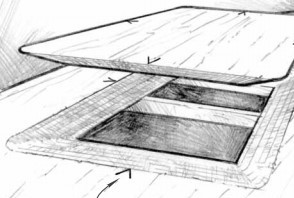

Cut a panel, from the same type of plywood as the original, to match the outside dimensions of the bevel. Use a disc sander to create a bevel on the inside edge of the replacement panel which should match the bevel on the opening. Then, dry fit the new panel so that it sits just slightly below the existing surface.

3. Bonding the panel

Start this stage by wetting out the bonding area of the panel with a resin/hardener mixture – recoating the end grain as necessary. Keep in mind that the plywood will absorb a lot of the epoxy.

Apply a mix of WEST SYSTEM Epoxy thickened with WEST SYSTEM 403 Microfibres, to the bonding area. The mixture should have the consistency of mayonnaise to form the most effective bond. You will need enough so that a small amount squeezes out when you push the new panel into position.

Next, clamp the new panel into position using temporary staples or screws. Clean up excess epoxy before it cures.

Once it has cured, remove the clamps and you’ll be ready to add the final layer of epoxy/filler.

4. Finishing

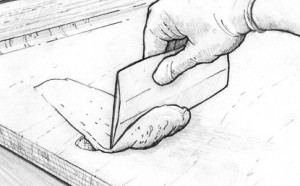

Start by sanding the surface carefully. Next, use a spreader to fill low areas with an epoxy/407 low-density filler mix which should have a peanut butter consistency. You should aim to slightly overfill low areas on the surface.

Allow the mixture to thoroughly cure before fairing.

For tutorials on using epoxy or to speak to one of our experts about your plywood project, head to the West System International support page.