How To: Four steps to repair barrier coating with epoxy

Barrier coating provides a great way to protect your boat against sun damage and moisture, whilst also supplying a smooth and stable base for your finishing coat. However, if the barrier coating has been damaged, you will need an easy way to restore the coating to ensure your boat is still protected from moisture. Here, we show you an easy and reliable way to repair barrier coating.

Before starting the repair process, it’s important to prepare the surfaces you want to protect by carrying out fairing on these areas. We recommend you begin the coating soon after this to avoid the possibility of surface contamination.

Once this is complete you can follow these four simple steps to ensure quality protection for your surfaces with strong and resilient barrier coating.

- Preparing the epoxy mixture

Begin by mixing small amounts of resin and hardener at a time – WEST SYSTEM 105 Epoxy Resin® and 205 Fast Hardener® or 206 Slow Hardener® will produce a high quality, protective coat with an opaque finish.

Using thin urethane disposable foam rollers, such as WEST SYSTEM roller covers, will give you greater control over film thickness

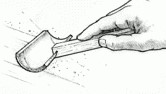

Pour the mixture into a roller pan and load up your roller with a reasonable amount of the epoxy mixture, making sure the roller is evenly coated by squeezing the excess out on the roller pan. Using thin urethane disposable foam rollers, such as WEST SYSTEM roller covers, will give you greater control over film thickness, leave less stipple than thicker nap-type roller covers and will stop the epoxy from building up and curing too quickly on the cover.

- Applying the epoxy

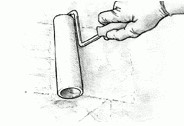

Roll the epoxy lightly and randomly over a small area – approximately 600mm x 600mm – spreading it into a thin smooth film. If you find that the roller is starting to dry out, you may need to increase pressure slightly but try not to roll too vigorously, as this may work air into the coating. Use long, light and even strokes to reduce roller marks and finish each batch by dragging the roller cover lightly over the surface, with enough pressure to smooth the area and remove air bubbles. Then, overlap and blend in the edge of the previous batch allowing the film thickness to become smooth. Now you’ll be ready to apply your next coat.

- Re-coating

It’s important to make sure the previous coat has cured firmly enough to support the weight of the next coat

Repeat these steps to apply your next coats of epoxy. For effective protection to the outside surfaces of your boat, you should apply a minimum of three coats (approx. 300 microns) of epoxy and at least six coats for those areas below the waterline.

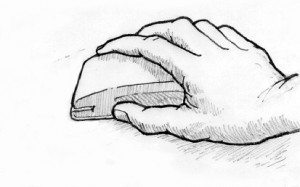

It’s important to make sure the previous coat has cured firmly enough to support the weight of the next coat – we have found that the best time to re-coat is when you are able to leave a gloved-finger indentation on the previous coat, without getting any residue on your protective glove.

Apply each coat in the opposite direction to the previous coat (e.g. first coat vertical, second horizontal, third vertical).

- Preparing for the final finish

After the final coat has cured thoroughly, you can either wash and sand or wet-sand the surface ready for final finish.

Are you looking to repair the barrier coating on your boat and give it the best protection against avoidable damage? Find all of the products mentioned on our website and get started.