Woodworking: Working With Nature, Not Against It – Kevin Varndell Designs

Limited to nothing but his own imagination, Kevin Varndell is driven by his passion for carpentry and the ability to create something completely unique in his own design.

Based in East Boldre, The New Forest in the south of England, Kevin has a career spanning 30 years in design and construction under his belt. As a full time builder, part time woodworker, Kevin’s designs combine the traditional and modern aspects of furniture making.

“I use traditional woodworking methods as well as thinking outside the box from time to time, using a variety of materials including wood, steel, plastics and resins.” When Kevin designs a piece, he can draw on this versatility to incorporate the different materials and give an overall more aesthetic design. “I find it immensely satisfying to create something of my own design, with no constraints, only my imagination to limit me.”

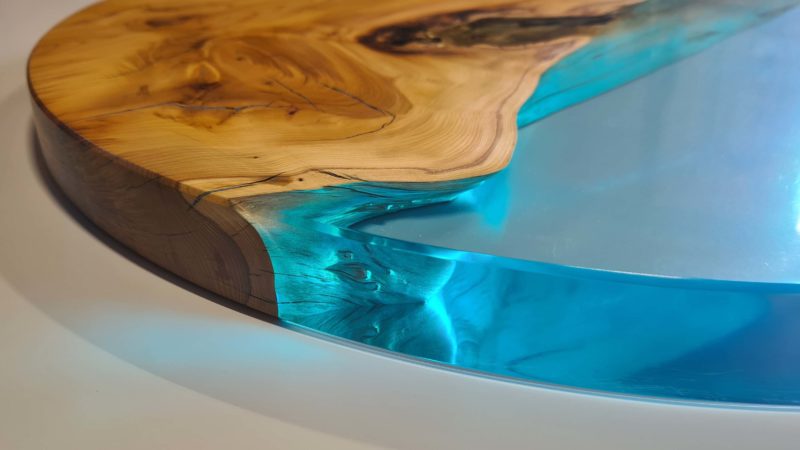

“I work with nature, not against it,” explains Kevin. “The knots, burrs and grain all tell the story of a tree’s journey through life. When buying mass-produced furniture, you get straight grain wood because it’s easier to work with, but sadly the finished is just a piece of wood with no story to tell.” At Kevin Varndell Designs, he believes that beautiful results come from finding the remarkable features in the wood, then highlighting and presenting them in the best way possible.

Kevin turns his hand to wall art, sculptures, traditional and contemporary tables, chopping boards, vases and much more. Kevin works on the entire process himself, from inception and design to completion. He sources locally produced wood for his projects and has built his own tools and machines for his workshop to unique specifications, in order to turn his unique ideas into a final product.

The 600 Year Old Table

Back in 2019, Kevin was commissioned to build a table using an oak wood that was over 600 years old. Designed for a local family and made from selected oak cut from ancient roof beams from a historic building in Hampshire that was undergoing restoration. “It was full of splits that needed filling and my plan was to use epoxy resin to fill these gaps,” explained Kevin. “I’d always bought the cheap epoxy online and often found it cracked when cured, but after some research, I discovered Wessex Resins and Adhesives just down the road from me. I spoke to Hamish from their Technical Support Team and he advised me on exactly where I’d been going wrong all these years and gave me some excellent tips on producing the results I’d been looking for.”

Hamish recommended Kevin use WEST SYSTEM Epoxy, and Entropy Resins for the thicker holes, on this project and we all agree that the results are beautiful. “Working with wood of that age can be challenging, but the end results were very rewarding. I used WEST SYSTEM 105/205 Epoxy to fill the gaps between the wood across the entire table and both the client and I were thrilled with the finished piece.”

Since then, Kevin has used WEST SYSTEM Epoxy on multiple projects, but the stand-out product for him is bio-based Entropy Resins, which is now the “go-to” epoxy for his river tables. “The best thing about working with Entropy Resins is not just the excellent results it provides, but it’s the lack of smell compared to others that you find on the market. There is no odour at all!”

Kevin currently works as a part-time furniture maker, with aspirations of turning it into a full-time business. Kevin’s website can be found here, as well as his portfolio of work.

You can read more on WEST SYSTEM Epoxy here.