Projects: Cheers! Leeds Furniture Maker Creates a Bar Worth Celebrating

James McKay has been a creator since his early years. His fascination for creativity guided his interest into art, design and technology during his school years. James went on to study at Camberwell College of Arts before completing a BA (Hons) in Furniture Design at Leeds Beckett University.

After finishing University, James jumped at the opportunity to train in his cousin’s traditional boat building workshop in America. “This is when I first gained hands-on experience working with epoxy,” James explains. After America, he returned to London, with a wealth of new skills in his arsenal. Friends and family soon started taking advantage of his expertise and James found himself building custom-made pieces for their homes. James moved to Leeds in 2005 when an opportunity came about to rent and work alongside other artists in a shared art space, before eventually building his own workshop in 2016. With over 25 years of experience under his belt, James has built a thriving furniture making business that focuses on custom made designs.

The Build

James takes a ‘If you can’t find it, I’ll make it!’ approach to his work. So when he was approached to build a specialised one-off wine bar for a private residence in West Yorkshire, James was eager to get stuck into the design and build.

“The client wanted a wine bar with a metallic, textured relief front to match a high-pressure laminate design they had found”. Unfortunately this laminate was discontinued so James looked at other ways to re-create the effect. One option that James considered was using an Artex™ style plaster render but after trials he was concerned about cracking and chipping.

When asked how he eventually created the textured front to the bar, James explained, “Assembling spruce masts in America I knew the best option for strength and to avoid fracture was to work with an epoxy system, specifically WEST SYSTEM® epoxy. I primed the surface with a mix of WEST SYSTEM 105 Epoxy Resin® and 205 Fast Hardener®.

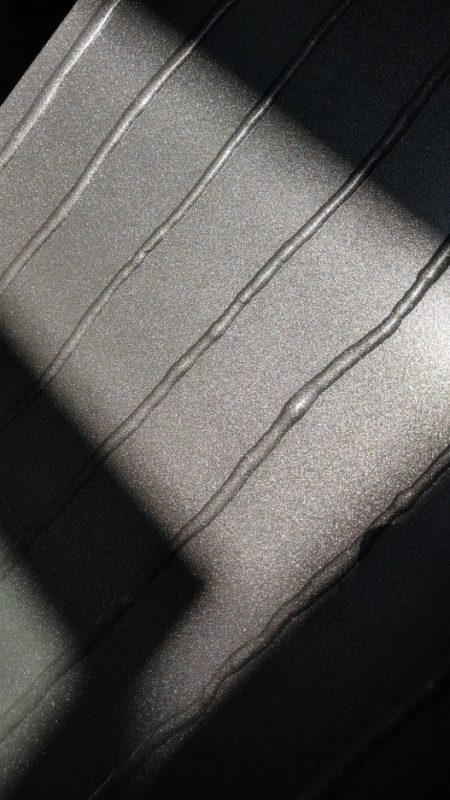

Once cured I then rubbed back with a Scotch-Brite™ pad dipped in soap and water to remove the Amine Blush. I drew pencil guidelines on the form with a traditional wooden line runner and then piped – with a cake making icing bag set – the beads and lines on by hand using the mixed epoxy with 406 Colloidal Silica added to thicken the mix and prevent slumping of the detailing whilst it cured.”

This final bar design is now standing proud in its new home, but the build didn’t fall short with its own abundance of challenges. “Controlling the flow of the epoxy was an initial concern and creating a design that would be durable was a major challenge from the beginning,” explains James.

James decided to contact Wessex Resins + Adhesives for advice, speaking to David Johnson, Sales Director. “I spoke to David and he advised how best to prepare the epoxy and recommended using WEST SYSTEM epoxy as a primer coat to achieve the protection the bar required – something I hadn’t considered initially – and how best to achieve the correct viscosity for the beading details. It was David’s great idea to use an icing bag to pipe the detail on.”

James’ stunning bar design standing proud in it’s new home

About the Creator

James has come a long way since creating furniture for his friends and family and continues to design beautiful builds from his workshop in Aberford, Leeds. You can discover more of his wonderful work at www.jsmckay.com or follow him on Instagram.