Projects: Using Bio-Based Epoxy to Shape Whisky Barrel Surfboards

These stunning whisky barrel surfboards were crafted with whisky barrels and made with Entropy Resins®. Although they’re destined for walls they’re true advocates for the beauty of well-used wood and crystal-clear epoxy.

According to Jason Burnett (Jay Surfboards), most surfboard shapers start making their products in a shed.

“I started repairing boards in a hut in my garden and it escalated from there – it started as a hobby and grew legs. Now I have a proper workshop,” he says from his home in Newbattle Abby, Dalkeith. It’s in that workshop which these beautiful boards took shape. Not destined for the water – although they are definitely usable – they take pride of place on the walls in Bladnoch Distillery.

Jason, a surfer who particularly enjoys Pease Bay on the East Coast, met David Prior (distillery owner) through their shared passion for surfing. Prior to buying the distillery – said to be the most southerly in Scotland – David had been making a blended whisky brand: Pure Scot. It was the barrels for that brand, combined with whisky barrel staves from Bladnoch, which make the boards so utterly stunning.

And, according to Jason, they smell pretty good too. “Once you cut them open they smell like sherry – they’re coated in that to help give them the flavour.”

Teamwork in creation

Jason isn’t the only one who’s enjoyed the residual scents. The boards are part of a joint team effort. The whisky barrel wood was processed by Frazer Reid from Far Cabinet Makers in Cupar who processed the staves. Frazer cut them and made them into 2mm thick veneers, prior to vacuum bagging the staves onto epoxy blank (foam core), and bonding the rails onto the side.

Once covered the boards went back to Jason who reshaped them to make them look like surfboards before using bio-based Entropy Resins to complete the process.

“I used one layer of 4oz glass fibre on each cycle for the top and bottom, with Entropy Resins epoxy. I added another layer of Entropy Resins epoxy to seal and then sanded them. Then I added the plugs for the fin to go in, sanded them down again and then added a finish coat.”

Jason used Entropy Resins CLR epoxy resin and CLF Hardener.

“They’re easy to use,” Jason continues. “I’ve never had any issues with the product at all. As soon as I knew the mix ratios I was away. The finish is completely like it is polished.”

We’ll raise a glass to that.

Whisky barrel surfboards – start with staves:

Whisky barrel staves processed to be vacuum bagged on to the eps foam core:

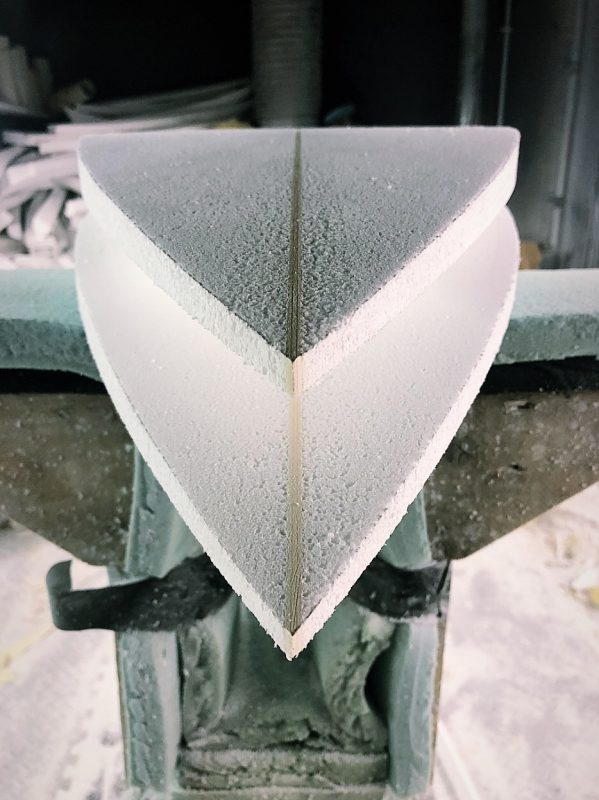

EPS foam cores:

Boards clad with the whisky barrel staves. Rails added and nose in tail blocks:

Boards shaped ready for glassing with Entropy Resins:

Laying the glass fibre:

Covered with bio-based Entropy Resins epoxy:

Finish coat applied:

In pride of place: