Projects: A Morris pick-up makeover

Wales-based boatbuilder John Jones has used his woodworking skills to renovate his beloved 1962-vintage Morris pick-up with a judicious use of WEST SYSTEM® epoxy.

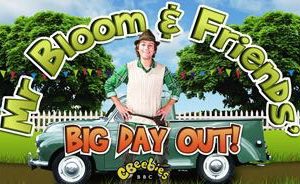

John Jones’ beloved Morris Minor 1000 pick-up, minus its rear pick-up. Incidentally, the flat section that runs from the bonnet right across the roof is where designer Alex Issignosis cut the prototype in half and added another 4 inches of width.

If the car looks familiar, you may have seen her featured in the C-Beebies series Mr Bloom and Friends, which explains the bright green colour.

The Morris Minor, or ‘Moggie’, has been likened to Doctor Who’s Tardis in that it travels through time pretty well. Designed during the Second World War by the father of the British Mini, Alex Issigonis, the Morris Minor and its variants were in production from 1948 until 1972, by which time 1,583,619 units had been made. Around 65,000 are still being driven on Britain’s roads today and one of them belongs to a talented restorer of classic yachts, John Jones.

“Moggie was a present – for a big birthday – from my wife, mother-in-law and daughters,” John explains. “The van was great and I drove it around for a year but then knew it needed a proper restoration job.”

Morris Minors are well known for their good handling and have been future-proofed by the dogged support of a select number of specialists who keep them on the road. As such, some 99.5% of all Morris Minor parts can still be obtained, many of them made in Sri Lanka in an open-air factory. Prices for panels and most of the main components are much cheaper than those for modern cars. However, John was about to learn what the 0.5% didn’t cover.

“When we decided to restore the Moggie pick-up, we soon discovered that while body work and parts are readily available, parts for the ‘pick-up’ section itself are not. Having a business in building and restoring wooden boats led us to decide that wood was the obvious answer.”

Classic Sail Boats Ltd not only creates beautiful custom vessel in clinker and carvel…

Classic Sail Boats Ltd not only creates beautiful custom vessel in clinker and carvel…

John opted for oak and oak-faced ply for the main part of the pick-up, with the wheel arches made by laminating thin strips of elm. He’s been building and restoring all types of boats for over 40 years and also specialises in custom items such as clocks and furniture. Compared to some of the projects they have undertaken, this was relatively straight forward.

“Using WEST SYSTEM Epoxy makes wood a very versatile material and hence it is feasible to keep to the original design,” John says. “Although the wooden pick-up is made of lots of pieces of timber, by using the bonding quality of WEST SYSTEM 105 Epoxy Resin and 205 Fast Hardener the structure becomes ‘as one’. This makes it strong and easy to maintain. It’s the same qualities we install in our wooden boats.”

Moggie is presently undergoing body repairs and painting.

If you would like to see more of John’s boatbuilding or furniture work or would like to discuss a commission, he can be contacted at: info@classicsailboats.co.uk or Tel: 07407 059699

Creating a pick-up shell in oak.

The basic framework is established around the chassis

The rest of the pick-up section takes a shape. Note how it is supported from the floor

John used oak-faced plywood for the panels and solid oak timber for the frame

The shape is completed with everything checked to ensure a proper fit and clearance from the wheels. Note the laminated elm wheel arches.

The pick-up unit can now be lifted off the vehicle for varnishing and detailing back in the workshop.