News: Lighter and stronger: epoxy – the ideal resin for laminates

The most popular resin systems for creating glass and carbon fibre composites are polyester and vinyl-ester. But WSI’s technical expert Gary Thompson isn’t a fan.

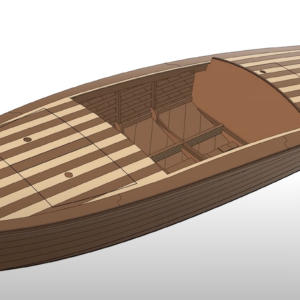

Fibre reinforced composite laminates are well known as being strong and highly durable materials used in many boat building applications.

In practice, you start by creating a composite laminate by ‘wetting out’ glass fabrics with different types of resins. You can then consolidate these either by hand in an open mould, or by using a vacuum bag and using atmospheric pressure to further consolidate the laminate.

But there are different types of resin used to do this. The most popular resin for creating glass fibre composites is polyester, with vinyl-ester coming a close second.

The argument you hear about why these thermoset ‘plastic’ resins are so popular is that they are of low cost and in terms of the cost per gram of the materials involved, this may be true. But in practice I believe that they often turn out to be more expensive and certainly take a lot more time. If considerations such as sail handling and ballast ratios are of concern to you (and they certainly will be if you’re a performance racer) then these so-called ‘cheap’ solutions will also make you less competitive.

The truth is that the physical properties of polyester and vinyl-ester resins make it difficult – if not impossible – to engineer composite parts that are both light and strong. To achieve the strength, you need to make the laminate thicker. This, in turn, makes the composite components far heavier. It will also take you much longer to build up laminate big enough to give you the strength that you need. This will mean less time on the water or, if you’re paying somebody else to do it, increased labour costs.

You can tell that I’m not a big fan of polyester laminations. Epoxy, it seems to me, is clearly a much better option. In fact, epoxy is the only resin system that will yield excellent laminate properties from aramid or carbon fibre composites.

Cured epoxy, after all, has a far higher tensile strength than either polyester or vinyl-ester resin. This means it’s possible for you to build composite components that are both lighter and stronger. There is also hardly any shrinkage from epoxy which means that cured parts have exceptional dimensional stability. Because of its excellent inter-laminar strength, epoxy is also particularly well suited to cored laminates in bigger boats.

For the experienced boat builder metering and mixing epoxy resin and hardener at the correct ratio is so much easier than the sensitive minute ratios required for polyester and vinyl-ester resins. It’s possible to always achieve a complete cure with epoxy – given good workshop conditions – whereas polyester and vinyl-ester are very sensitive to workshop temperature changes. Although good housekeeping and health and safety practices must be employed in any laminating shop, composite laminating or infusion epoxies contain no solvents or styrene, allowing a far more acceptable working environment.

I think it’s also important to point out that epoxy is far more water resistant than other resin systems, which is clearly a strong selling point when talking about marine environments. This rather convenient feature of epoxy makes it virtually blister proof and ideal for withstanding harsh marine conditions above and below the waterline.

Not all epoxy laminates are the same

While epoxy in general offers superior physical properties compared to other systems, not all epoxies are the same and not all are particularly well suited to laminating. What’s required is a specialist, low-viscosity epoxy created especially for the task in hand.

The market leading product that is designed for this job is PRO-SET® epoxy. The physical characteristics of the range of PRO-SET Laminating (LAM) epoxies are ideally suited to wet lay up techniques, with vacuum consolidation recommended for creating the ideal laminate. All the products in the range feature a very low viscosity which means they are able to easily impregnate glass cloth, as well as carbon and aramid fibres.

They can also be used with a variety of hardeners to extend or reduce cure times, depending on the size of the project. In fact it’s even possible to combine hardeners to achieve exactly the cure time required.

Epoxy resins and hardeners are, therefore, a far better way to create laminate structures for marine applications. Not only are they far stronger than the more common alternatives but they are very much lighter, which makes them perfect for performance boats. But perhaps most important of all is that they are built to last. Epoxy and water simply don’t mix. At all. That means that epoxy laminates will be around long after the polyester and vinyl-ester laminates have blistered their way to a rather leaky end.

Now approved by Lloyd’s Register, PRO-SET Laminating epoxies are among the most trusted in the marine industry. Find your nearest stockist.