News: A world of innovation

The JEC Composites show in Paris was packed with exciting applications for lightweight composites. So whether you want a carbon-fibre drone, a surfboard with hydrofoils, or a solar-powered car, you’ll find one at the show.

The annual JEC World show at the Paris-Nord Villepinte exhibition centre runs for three days in early March and is a must-attend event for movers and shakers in the composites industry. West System International’s David Johnson was there manning the stand to showcase what is possible with the range of PRO-SET® epoxies – used extensively in the manufacture of composite parts. He also had the chance to have a quick look around, although he admits there was so much on offer it was impossible to see it all.

“JEC was excellent for us,” he said. “It is the flagship for the composites industry in Europe but always attracts a global audience. We have been there as exhibitors for over 18 years and seen it grow in proportion to composite users in all branches of industry.”

Products like PRO-SET INF Infusion epoxy can be used for any application that benefits from vacuum infusion, a process where epoxy is propelled through reinforcing materials by atmospheric pressure. Infusion guarantees an even distribution of the epoxy and when combined with light and strong fabrics such as carbon fibre or with foam core, the possibilities are endless. Little surprise, then, that there was a wide array of new materials and machines on show aimed at making the infusion process even faster to create products that are lighter and stronger than before.

JEC World also runs an award scheme to identify the areas of composite production that are making the biggest advances. The shortlist of 10 finalists was wide-ranging, especially in the transport and renewable energy sectors with some very exciting innovations.

For the WSI team, the event is also the chance to catch up with contacts from all over the world, as the exhibition centre is well placed just a few minutes from Charles de Gaulle airport. This networking leads to some very worthwhile collaboration.

“We had an excellent stand location and received a number of very promising enquiries,” David said. “We met many of our WSI family of European distributors and also many of our existing customers which led to some strong sales leads. This gives us invaluable feedback, which we will use in our ongoing programme of product development.”

These are some of the most relevant – and eye-catching – exhibits we saw at JEC World to inspire you in your next PRO-SET epoxy project.

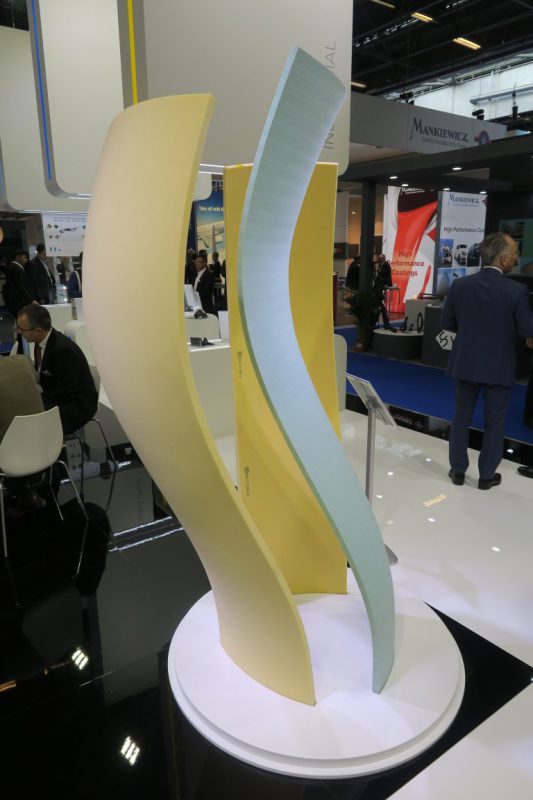

BEND IT LIKE BECKHAM

The trouble with rigid cores is that they come in flat sheets. But did you know that the Dutch company Curveworks can bend a thermoplastic foam core board into any shape you want? Just sketch what you need with measurements, or better still send them the CAD drawings and a special computerised heat press will warp the core into a three-dimensional shape. Once cooled, it sets rigid again. This is a cheap way to prototype any product that requires the infusion of a curved core.

Visit: www.curveworks.nl

A CUT ABOVE

Automation is becoming a key process in many infusion processes, with cutting machines able to trim large sheets of reinforcement into exact shapes and so minimise waste. We saw a new range of laser cutters, routers and even a machine that sews wires and carbon filaments into reinforcing cloth. This allows extra material to be placed at key stress points.

Visit: www.zsk.de or www.eastmancuts.com

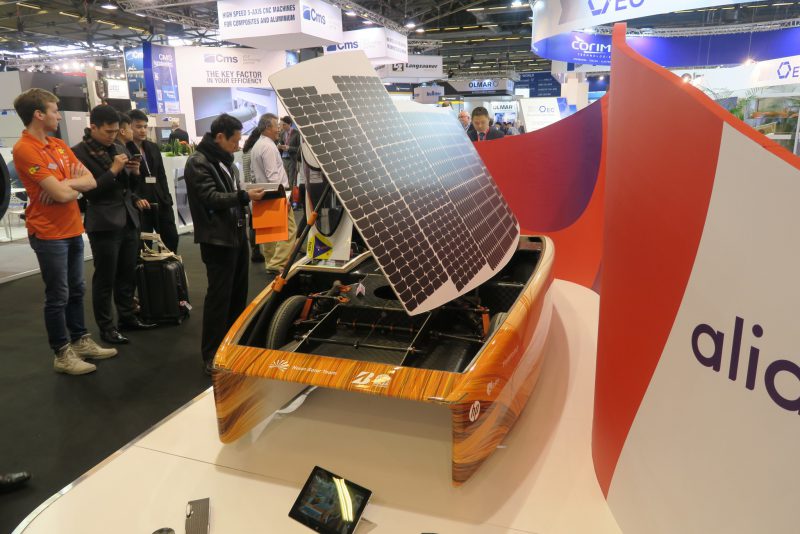

A RAY OF SUNSHINE

Composites can create incredibly lightweight and rigid structures, so they are widely used in low-energy and experimental cars. At JEC we saw this remarkable electric car from the Dutch-based Nuon Solar Team, with which they ‘convincingly’ won the Bridgestone World Solar Challenge in Australia last year. The car weighs 135kg and collects energy from 2.64m2 of Gallium Arsenide solar cells, which it stores in a 5.1kWh lithium Ion battery weighing 20kg.

Visit: www.nuonsolarteam.nl

CARBON TYRE PRINT

As you will see from the feature on J-TEC, infused carbon with PRO-SET INF epoxy can give some really stylish custom bodywork. Carbon composite cars were on display all around the show, along with a range of lightweight components being trialled by legends such as BMW and Porsche. Here are two extremes; the 600hp Ligier JS P217 Le Mans prototype by Onroak Automotive and the composite shell of the new Swedish electric car Uniti. Composite processes will allow mass production of the Uniti, which will deliver a range of 186 miles per charge and performance of 0-50mph in 3.5 seconds. The car will be available from 2019 for £12,980, with a production run of 50,000 a year.

More information: www.onroak.com and www.uniti.earth

FOILING SURFBOARD

Why bounce over the waves whilst kite surfing when you can fly over them instead? This two-component foiling leg is called Project Cedrus and consists of a buoyant vertical support that connects with an arrangement of epoxy-infused carbon fibre foils. The result is a detachable ‘wing’ that will effortlessly lift you a metre above the chop and give you a smooth ride at high speed. To get the rig ashore, just flip the board over when you reach shallow water. Four hex screws set into slots allows for quick removal and stowage. Awesome, dude.

Contact: Adherend Innovations LLC (USA)

UBER BY WATER

The Seabubble project is ‘an on-demand urban transport network that uses the waterways of major cities.’ Currently being trialled in Paris, each water taxi consists of an infused cathedral hull set above two sets of rigid foils. Power comes from a pair of electric motors set behind the rear foils, with the battery recharged from renewables, mainly solar and tidal flow captured by the Seabubble’s dock. The boat lifts up on foils at around 7mph and can reach speeds of 25mph with 5 passengers aboard. Each Seabubble (minus dock) is expected to retail at around €33,000 ex VAT.

More at: www.seabubbles.fr

COMPACT PLANES

At the back of hall 6 was Aero Planet, a collection of composite aircraft, including a rather sinister looking drone. Composites, especially in a ‘monocoque’ design (a one piece structure, for extra strength) allow for airframes that are very light and – crucially – won’t suffer from corrosion and metal fatigue around rivets. Centre stage was this sleek little two-seater from the French OEM Elixir Aircraft. This pioneering model weighs just 265kg empty and has a Rotax 915iS engine giving a climb rate of 1,580ft/min and a cruising speed of 153 knots. Yours to fly away for €150,000 ex VAT.

Visit: www.elixir-aircraft.com

DROP IN ‘WET CORE’ POD

Fitting a kitchen, bathroom and laundry (wet room) into a flat or small apartment is the most time consuming and expensive part of a new build or refurbishment. This is due to the amount of plumbing, tiling, sealing and wiring required. So why not make the whole thing off-site as a pre-cut module and in easy-to-clean composite. When the building work reaches the right stage, just crane the whole unit in. A few connections and the Wet Core Pod is good to go.

Contact: MC Materiales Compuestos (Argentina)

Next year’s JEC:

If you are a professional working with composites, or just want to learn more about this fascinating subject, then you need to get along to next year’s show.

JEC World 2019 will be held in the same location from 12 to 14 March 2019.

There is no language barrier as English is spoken throughout the show including the seminar presentations, which showcase specific innovations.

There are plenty of affordable hotels nearby and regular flights from all over Europe. If you want to rest your weary feet then a warm welcome, a chair and a hot drink await you at the PRO-SET epoxy stand.

More 2019 programme information at: https://www.jeccomposites.com

Canoe infusion courses with PRO-SET INF epoxy

If you want to get hands on with PRO-SET INF epoxy there is no better way than with a professionally geared PRO-SET epoxy course with West System International UK.

Since the courses started, delegates from 10 different countries have built a total of 14 canoes, infusing 4kg of PRO-SET infusion epoxy resin each time. There have also been experiments with a wide range of reinforcements, including biaxial woven carbon, unidirectional-carbon, carbon & aramid hybrid tape and Lantor coremat.

These two-day courses are always well attended by PRO-SET epoxy users and distributors, many of whom can fly in to nearby Southampton Airport and are coupled with WSI’s legendary hospitality.

You can watch our infusion video and find more at: wessexresins.co.uk

Hamish poses with the finished result, a Gougeon 12.5ft Canadian-style canoe.