News: Experimentation with ENTROPY RESINS

David Johnson (our sales director) recently visited Turkey to run an ENTROPY RESINS® workshop. As he and the delegates discovered there is something really satisfying about being let loose on the creative projects that you can make with ENTROPY RESINS Clear Casting Epoxy – a bio-based clear casting epoxy.

Hosted by Sema Carckci of Etap Marine (the Turkish distributor for ENTROPY RESINS) in her Istanbul premises, the 25 delegates enjoyed a variety of activities including River Tables, penny casting and, obviously, making a surfboard.

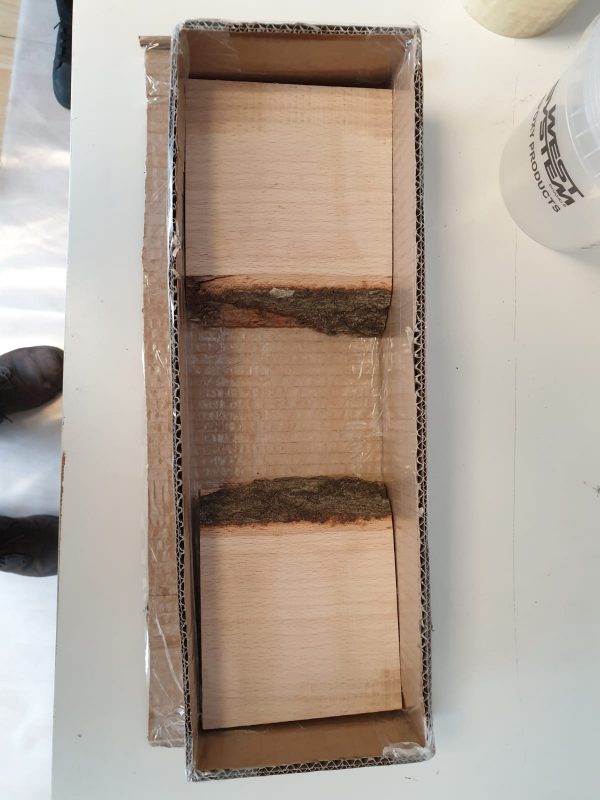

The day began with David demonstrating how to make a ‘starter’ River Table in a cardboard mould lined with sellotape (25mm depth), before graduating to casting a five-litre volume River Table (50mm depth) with ENTROPY CCR Clear Casting Epoxy and CCS Slow Hardener. Then it was a Tree Section table (85mm). On the first two projects, the second pour took place four hours after the first. The tree section second pour was 12 hours later because of the depth.

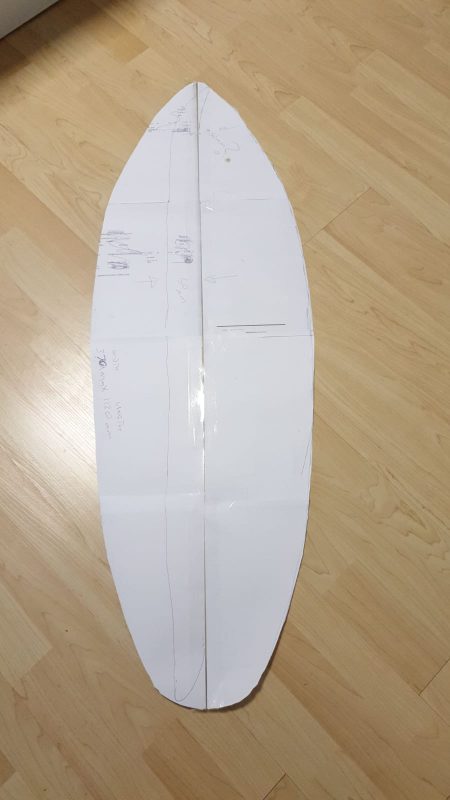

Ever resourceful, David used a paper pattern to make a mini-surfboard and sourced three pieces of polystyrene / EPS foam from a skip. These were laminated with ENTROPY CLR Clear Laminating Epoxy and CCF Fast Hardener and colour pigmented style accents to make the impressionist design of a French flag on the board.

At the end of the day, all the delegates cast a keyring or jewellery in a silicone ice cube tray and made chess pieces from silicone moulds.

“It was brilliant,” says David, “to be with such enthusiastic people who could see the limitless possibilities of the product. We’re very excited about ENTROPY RESINS and its possibilities and potential. Obviously it’s been quickly adopted by the surf market for laminating boards worldwide and now it’s being adopted by all sorts of makers. We love to see the projects that keep appearing!”

And as for the surfboard? That’s heading out to sea with Sema’s son. Fingers crossed he has a ‘swell’ time!