News: Additive of the Month – October 2018

HIGH-DENSITY FILLER (Type: Finely milled adhesive filler. Product No: 404)

What is it? Originally designed to fix wooden blades to a wind turbine hub, 404 High-Density Filler is a very fine powder used for bonding hardware into substrates. When mixed with WEST SYSTEM epoxy, the cured material is highly resistant to compression and intense cyclic loading.

Used for? 404’s resistance to any form of distortion makes it ideal for filling voids that are going to be subjected to big loads. Prime examples would be padding out the gaps beneath a winch drum, or replacing a rotted balsa core deck under a cleat. It can also be used for filleting and gap filling.

Mixing ratio: The High Density Filler can be added to a WEST SYSTEM resin and hardener mix at anywhere between 35% to 60% by weight, depending on the viscosity needed. A thick paste, towards the 60% end, would typically be used where access is easy, and the ‘peanut butter consistency’ paste can be applied with a palette knife. The more fluid mix would be used where it has to be decanted or injected, such as into a bolthole.

Hamish’s Tip’s for the 404 filler:

“The 404 High Density Filler is the real workhorse of hardware bonding,” Hamish says. “Once cured, it is remarkably strong, and can withstand loadings of several tons. When a deck fitting is faced with excessive loads, it is usually the substrate that gives way before the 404-reinforced epoxy.”

Wax the fittings you may want to remove

“Because 404 is an adhesive filler, it will glue itself to any non-slippery surface. If you want to use it with hardware you may want to remove later, you will have to grease the contact surfaces. We recommend using a mould release wax such as Maguire’s. Coat the threads using a cloth, but then remove the excess in the threads by pushing a fingernail through the cloth and into the groove. (Excess wax will make the grip less effective as it will displace the 404.)

Use the ‘x times 6mm’ rule

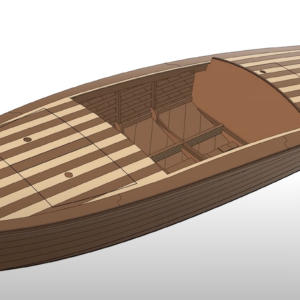

If you plan on capturing a fitting, then a useful guide is to drill an oversized hole 6mm wider than the bolts or screws you intend to use. This will give 3mm all round the thread for the 404 mix to occupy. The photo shows a cutaway of a typical bolthole. Note the end of the bolt sits in a pilot hole to keep the bolt upright, whilst the upper part is a void with 3mm all round. Once filled with 404, the bolt will be held rigidly in place, but could be extracted later if properly greased, as it will have moulded itself a thread. Note that the nut can be encapsulated too, a good way to hold the bolt vertical, or left on the outside if preferred to aid extraction.

The ‘X times 6mm’ ratio works well for most sizes of deck fitting. If the hole was too big then the large column of epoxy mix needed may well ‘exotherm’ once it was poured in. This self-generation of heat creates air bubbles and could compromise the filler.