News: Additive of the Month 405 Filleting Blend, perfect for making a wood fillet

How to make a wood fillet using this adhesive filler.

What is it? A fillet is a coved shaped bead of thickened epoxy that bonds to the outside of two surfaces to lock them together. Being an external bond, rather than hidden behind the wood, a fillet has to look good, so WEST SYSTEM 405 Filleting Blend is a mix of colloidal silica and timber-coloured microfibres.

This carefully formulated mix gives a pleasant hardwood-style finish to the seams of any boatbuilding project.

Used for?

As the name suggests, filleting. This is one of the most common uses for this type of thickened epoxy mix. It is great for building structures that link panels or planks together with a visible epoxy seam and used properly is key to how to make a wood fillet look good. The picture shows fillets (in brown) being used both horizontally and vertically to bond this toolbox together.

Not exclusive:

Fillets can also be made using other additives, such as WEST SYSTEM 406 Colloidal Silica as seen here in this attractive pale fillet on a rich mahogany ply. However, for most general-purpose fillets, especially in wooden boat building, WEST SYSTEM 405 Filleting Blend contains the ideal combination of colour and consistency. But this additive doesn’t have a monopoly.

Best mix:

The instructions on top of the container indicate the right mix for each additive. The filleting blend requires a 1:1 by volume addition of filler to resin and harder mix to achieve a peanut butter consistency.

Each WEST SYSTEM 405 container includes a plastic spoon, calibrated so that two heaped scoops matches one stroke of resin and hardener mix from the standard WEST SYSTEM 105/205 epoxy pumps. This will provide the perfect mix.

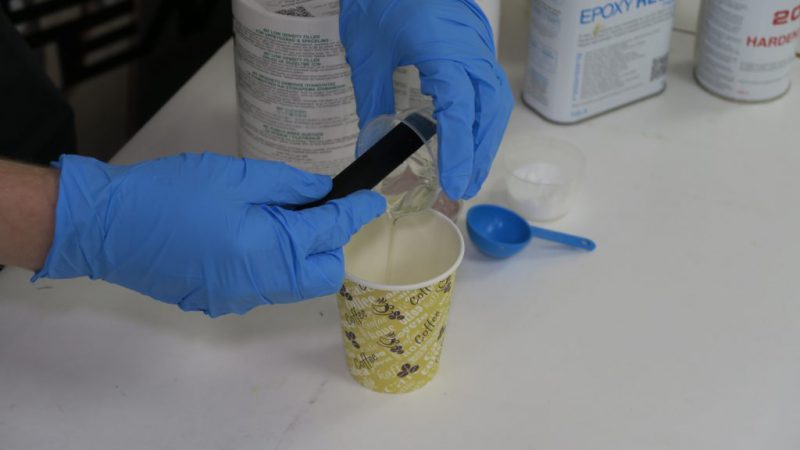

Decant the required number of pumps from the resin and hardener. This will be the amount you can work with in the curing window of about 20 minutes at an ambient temperature of about 20 degrees. Mix together thoroughly before introducing the additive.

If you don’t have pumps, then the ratio is 25% addition by weight of WEST SYSTEM 405 to a WEST SYSTEM 105/205 mix – but it is easy to mix up by simply adding filler in small amounts until the consistency feels right.

Hamish’s filleting tips:

As with Colloidal Silica, scooping filleting blend straight out of the container will involve a bit of dust, and the mix is very light and flyaway. A mask is recommended.

A quick tack

“If you want to quickly bond two pieces of wood together prior to filleting them, then a bead of WEST SYSTEM G5 epoxy is the answer. The resin and hardener are mixed at a ratio of 1:1 and will cure in 5 minutes at room temperature.

“I usually use the WEST SYSTEM G5 pots themselves to wedge a vertical section in place as it dries, typically when we’re making plywood tool boxes from kits as part of the basic epoxy course.”

Go for peanut butter

“Filleting blend works best when mixed to a ‘peanut butter’ consistency. This means that when you scoop it onto your filleting tool, the material retains its shape, and doesn’t slump back on itself.”

Use the rounded edge for sculpting

“The radius on a WEST SYSTEM mixing stick is ideal to make an average size fillet. Better still, the stick is made of a shiny plastic, which can be reused over and over again. (The epoxy can be wiped off its surface when wet, and snapped off when cured).

“Simply run the filleting mix along the seam, adding more mix as you go to ensure an even fillet. It doesn’t take long to become very good at this.”

Chisel edge for tidying up

“The mixing sticks have a chisel edge at one end and this is ideal for scraping up the inevitable waste left by the filleting action. Scooped back into the pot, it is ready to be reintroduced into the next seam.”

Big fillets? Use the scoop!

“That blue plastic measuring scoop has another role – you can use it as a shaping tool for extra-large fillets. Just run it across the fillet mix as you would with a mixing stick. You may need these bigger fillets if connecting heavy sheets of plywood, for example, such as when making a battery box.

“You can also cut the edge of a ‘squeegy’ scarper to custom make a fillet of any radius, as shown here.”

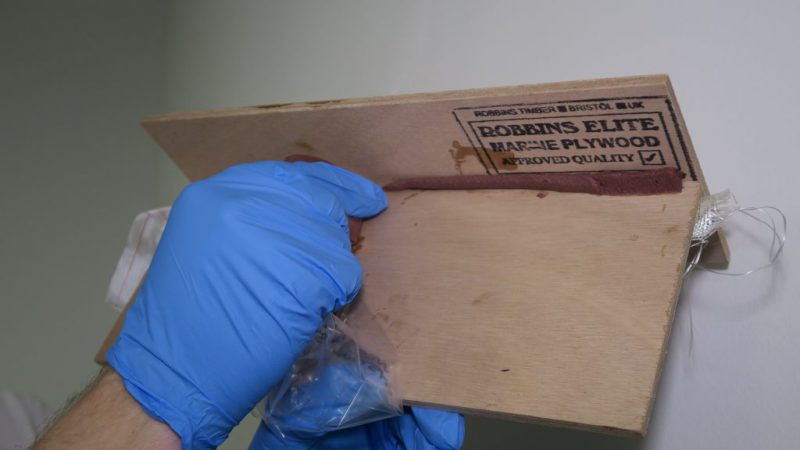

Use a bag for overhead work

“If trying to fillet directly overhead, don’t risk the filleting blend dropping off the tool and into your hair. Instead, put the material into a plastic bag, screw it up onto a cone, and then cut off the end. This is how cake makers apply the icing.

“By squeezing the bag, the filleting epoxy will be squeezed out into a bead that can be applied to the seam with no loss to gravity.

“Once it’s up there, follow through in the usual way with the mixing stick to shape the bead into a fillet.”

Try some peel ply

“The nature of the filleting mix means you get a slightly uneven textured finish once cured, which may need laborious sanding to make smooth.

“Instead, a good tip is to lay a piece of peel ply along it, and smooth it down. Peel ply is made from nylon, is very inexpensive and is widely used in epoxy work.

“Once the fillet has cured, the peel ply is easy to peel away (as the name suggests) leaving a smooth, textured surface but with a shallow imprint of the ply. This will provide a great key for any further epoxy work. The peel ply will also take away any amine blush.”

Finish with unthickened epoxy

“A pleasing finishing touch is to paint a resin/hardener mix over the top, and continue this onto the wood itself. This gives a final seal to the fillet, and helps in blend in to the rest of the structure, especially one that will eventually be varnished.”

if you have any more questions about how to make a wood fillet get in touch with our knowledgeable technical team.