How To: Q&A with Naval Architect Andrew Wolstenholme

Andrew Wolstenholme is the renaissance man of naval architecture. He’s designed everything from classic broads sailing yachts to production powerboats and gentlemen’s launches, and he’s more prolific than ever. Epoxycraft asked him how he first got interested in boat design; what drives his design philosophy and why so many of his boats use wood/epoxy construction techniques. Here’s what he said…

Q: How did you first get interested in yacht and boat design?

A: Where I went to grammar school in Morecambe there was a small Graduate sailing dinghy in the corner of the woodwork workshop. When it was finished, some older kids dragged it over to the beach and launched it, which seemed like great fun. I joined the local sailing club with a few pals and I was hooked.

Q: How did you become a Naval Architect?

A: I was planning on studying aeronautical engineering at university, but I was mad on boats and there was a new yacht design course that had just started at Southampton College of Technology the year before. Credit to my parents, they let me do it, and I’ve been on that path ever since.

I only had two jobs before I decided to work for myself, which meant I had to knock on lots of doors to get my designs built. I was already in Norfolk at the time, and I was drafting designs for local boat yards, including the one owned by Jack Chippendale, the prolific and renowned racing dinghy builder. At the same time, I was contacting GRP powerboat builders, charter boat builders and anyone else who could give me work. I’m interested in all types of boats and not limited to any particular style, which is probably why my portfolio is still so diverse. There are even RNLI training boats built on my original Hardy 42 design for a Hardy Marine.

Q: What’s better, GRP or wood/epoxy?

A: It absolutely depends on the brief. For a volume production boat moulded GRP is the best choice but wood/epoxy is often best for custom builds where only one or two boats are planned. There are other benefits to wood as well: it has great structural properties, it’s beautiful to look at and to live with and – in conjunction with epoxy – can be as durable and low-maintenance as GRP.

Q: What is your connection to Norfolk?

A: I came here in 1976 to work for Landamores so I’ve been here for a long time now. In the early 80s, I worked with a local boat builder called Kingsley Farrington on a traditionally styled 25’ Broads cruiser that had a GRP hull and timber superstructure – that was my first design to be launched. It was quite controversial at the time with much debate over whether GRP hulled boats should be allowed into the very traditional River Cruiser Class with its fleet of classic timber yachts. It was a successful design though and there are about 30 or 40 of those about now.

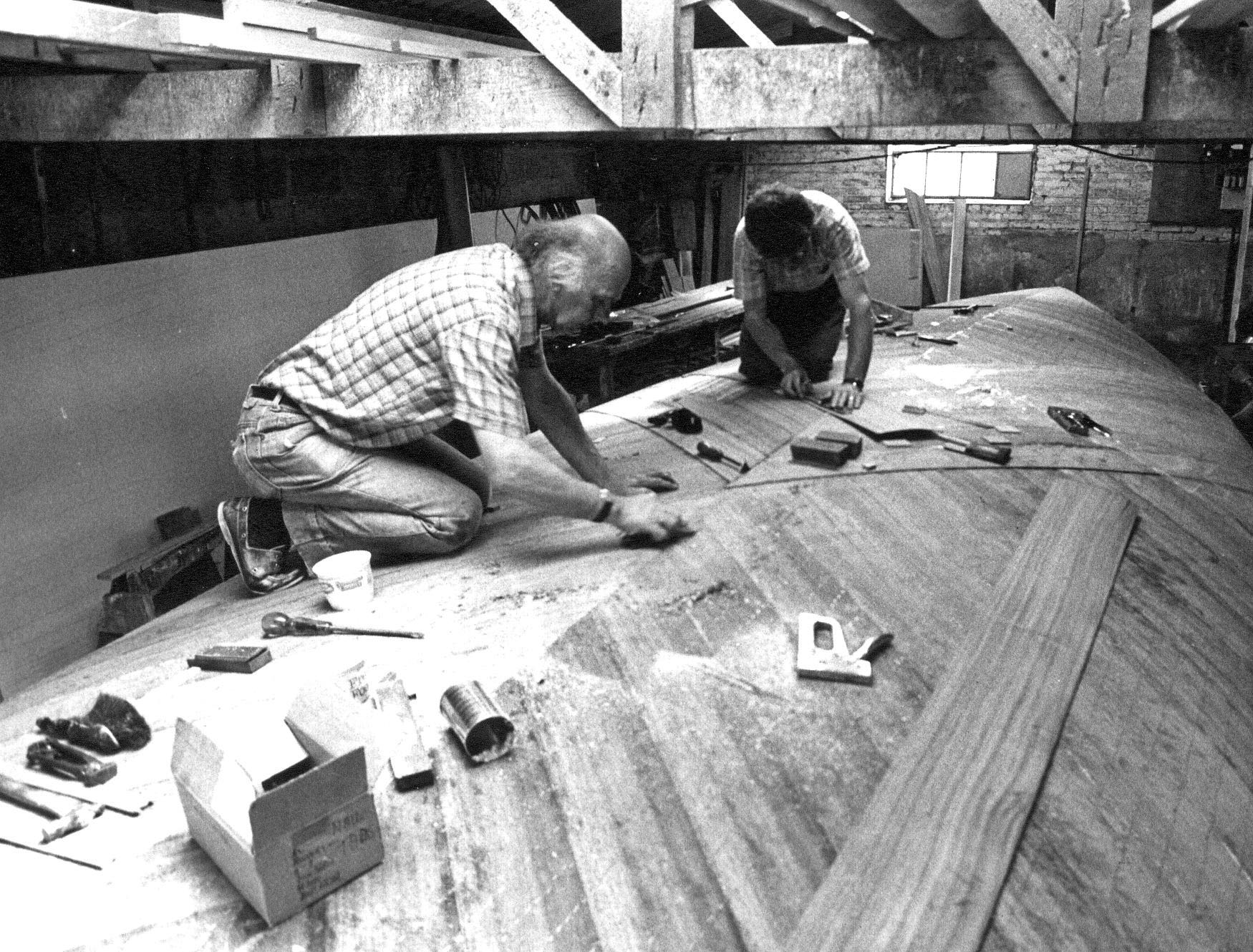

Whilst the 25 was in development, and in fact inspired by her, Richard Mace commissioned the design for Cirrus, a 33’ cold moulded wood/epoxy Broads yacht, and she in turn paved the way for an even bigger 35’ fast Broads racer called Storm that was also really special. Storm was built by Jack Chippendale and was cold moulded with 3mm mahogany veneers giving her a very light, strong hull, and she was (and arguably still is) the fastest boat on the Broads, which was exactly what the owner had asked for.

Whilst the 25 was in development, and in fact inspired by her, Richard Mace commissioned the design for Cirrus, a 33’ cold moulded wood/epoxy Broads yacht, and she in turn paved the way for an even bigger 35’ fast Broads racer called Storm that was also really special. Storm was built by Jack Chippendale and was cold moulded with 3mm mahogany veneers giving her a very light, strong hull, and she was (and arguably still is) the fastest boat on the Broads, which was exactly what the owner had asked for.

Richard Mace sold Cirrus some time later, but he regretted it so much that he had a replica built on the original design in 2013, which he called India.

Q: Why are so many of your boats built with wood and epoxy

A: When I was at college, people were just starting to build with wood and epoxy and I count myself as part of that movement. We realised we could build lighter, stronger boats that required less maintenance using epoxy. The Gougeon Brothers and WEST SYSTEM are one of the key catalysts that has driven the wooden boat revival (whether traditional or modern) and that in turn has encouraged the continued evolution of marine-grade epoxy and epoxy construction techniques over the years.

Q: Are wooden boats better than they used to be because of epoxy?

A: I suspect that some traditional wooden boatbuilders may disagree, but yes, I believe that they are. Before the advent of effective marine glues wooden boats were nailed together and over time components would be likely to start to move and so there was a much greater risk of water ingress. Having said that, the 19th and 20th Centuries were incredibly innovative times in terms of boat building and I’m always amazed at what builders could achieve with the materials they had available. We’re no more intelligent or skilled today – we just have better materials, and marine-grade epoxy resin is just one example of that.

Q: How would you describe your own designs?

A: I’d like to think that they are elegant, but that’s not just about how they look. Being elegant is also about finding the best solution to a design brief, and looking for ways to design and build boats that are efficient, cost-effective and able to deliver the best performance. Elegance covers all of these things and more and it’s at the heart of my design philosophy.

Q: What are you working on at the moment?

A: I’ve got four wood epoxy designs on the go. Two of them are small dinghies: a 16’ Norfolk Punt, which is a double-ended racing dinghy and is being built at IBTC Lowestoft; and a knockabout dinghy for the Old Gaffers Association, who wanted something to get youngsters interested in sailing. Then there’s a 30’ foot strip-planked electric Broads motor cruiser, which is being built by Colin and Paul Buttifant at Swallowtail Boatyard. The final wooden boat I’m working on is a 20ft single-chime plywood day sailer being built by Upsons of Aldeburgh, which will have an electric auxiliary motor.

The GRP projects I’m working on are a 24’ classic yacht for Cornish Crabbers and a 35’ Duchy powerboat for Cockwells. The last one is a 29’ landing craft or “bow-door boat” for Jim Coulam Boatbuilders which follows on from the 20footer we built for the Wheelyboat Trust that gives mobility impaired people the chance to get out on the water in wheelchair-accessible boats. I have also been working with Cockwells on some Superyacht tenders, which use epoxy infusion for hull construction.

To find out more about Andrew and his work, visit his website.