Projects: Two products for top performance

Based in West Yorkshire, Winder Boats builds high performance racing dinghies and foils using PRO-SET epoxy. The key to success was finding the right product and – literally – sticking with it.

Anyone who has sailed a Merlin Rocket or Fireball dinghy knows the exhilaration they give from close racing in a stiff breeze and the international competition is as fierce as it gets. As such, these boats need to be as light and as strong as possible, which is why Winder Boats moved away from working solely in plywood a decade ago and now creates a range of composite hull types using PRO-SET epoxy.

As business partner David Winder explains, they found that two products could do just about every job in the workshop, which keeps the inventory low and the skill set high.

“We use PRO-SET INF Epoxy (INF-114 Resin with a combination of 211 or 213 INF Hardeners) for infusion, and PRO-SET LAM Epoxy (LAM-125 Resin with a combination of either 224, 226 or 237 LAM Hardeners) for hand lay-up and general bonding,” David said. “Infusion is a great way to make a moulding but sometimes you can get a better result by using hand-applied epoxy, especially if the mould tool has some awkward shapes. The Merlin Rocket, for example, has a mock clinker design, where the ‘planks’ overlap. This lends itself more to using a hand-layup technique, as you can insure full epoxy saturation by working it into the turn of each join.”

The switch to composites

Guy Winder founded his company in a garage in 1976 to make a range of sailing dinghies, from popular trainers such as Mirrors and GP14s up to white knuckle ride Merlins, Solos and Fireballs. The family are racing enthusiasts so they live and breathe their products and the company has since grown to employ 5 more staff. The website states ‘A winder boat is not just built to win championships, but also built to last.’ The company is also able to customise the designs, so can supply a Mirror with an outboard bracket and rowlocks, or a GP14 that is tough enough to withstand serious abuse.

“We were originally building everything in wood but realised we could get a lighter and lower-maintenance product if we switched to fibreglass or epoxy composite,” David said. He joined his father’s company straight from school in 1986 and now leads the production team in development and innovation.

“We had to teach ourselves the techniques and began with using infusion on the top-end dinghies,” he said. “We approached West System International (WSI) for advice and resident expert David Johnson came up to help us.”

The first composite Merlin Rocket was created in 1989 and proved a huge success, so the processes were moved across to other boats in the portfolio, including National 12s. Initially, Winder Boats had begun by using another manufacturer’s epoxy and whilst effective they found that it was not particularly user friendly.

“We had always kept in touch with David at WSI and when he told us that they had a new formulation of PRO-SET epoxy coming out, we asked him for a demonstration. We found the PRO SET LAM and INF epoxy products to be exactly what we wanted. They have virtually no odour and by using a blend of hardeners we can get the epoxy to cure at exactly the right speed for our production schedule.”

David Winder’s main concern was the effect of temperature on a dark hull as many international events are held in very hot climates. However, the PRO-SET INF epoxy was already post cured at 60oC and proved indestructible, even when a dark hull was being sailed hard in the Tropics. “I raced one of our PRO-SET epoxy Fireballs during the World championships in Carnac, Brittany, this year,” David said. “It was August and in the middle of a record-breaking summer. Despite the blistering heat, it didn’t cook. The layup is incredibly stable.”

Speed of production

Apart from the low emissions and customised cure times, the main reason Winder Boats likes to use PRO-SET INF epoxy is the speed at which a hull and deck can be made.

“The process is also very easy to teach to new staff,” David said. “The hull can be assembled by one worker in the morning and infused during the afternoon.” (See our feature in Epoxycraft on the whole infusion process, or watch our video)

With another worker assembling the deck, a boat can be put together in a day.

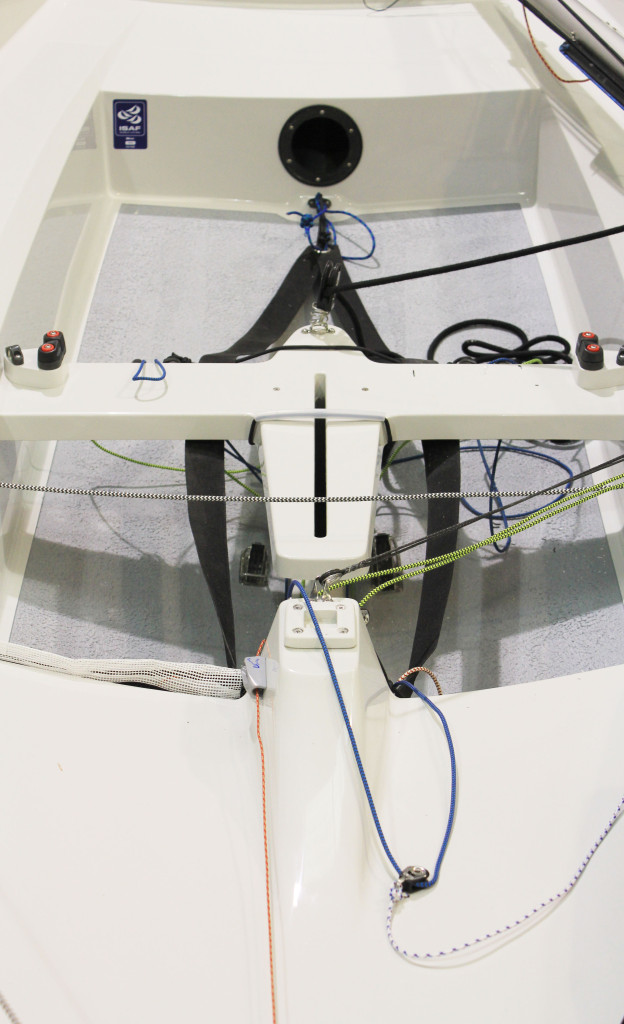

“We use PRO-SET LAM epoxy to bond the hull and deck together and to create other smaller components. The foils are also infused, with either kevlar or carbon, depending on class rules or a customer’s requirements.”

The infusion process pulls the INF-114/211 epoxy evenly throughout a mix of reinforcements chosen for their strength-to-weight ratio and includes 300gsm woven glass cloth and the strategic use of foam cores. The hand lamination is reserved for smaller components and the inside of the Merlin Rocket’s hull.

“With the hand process, you can target the epoxy more precisely, so it is possible to make a lighter moulding. However, infusion gives an excellent product, with an even distribution of epoxy, although you have to be very diligent with sealing the vacuum bag. The slightest leak can compromise the whole process, so we are particularly careful with bag integrity.”

“With the hand process, you can target the epoxy more precisely, so it is possible to make a lighter moulding. However, infusion gives an excellent product, with an even distribution of epoxy, although you have to be very diligent with sealing the vacuum bag. The slightest leak can compromise the whole process, so we are particularly careful with bag integrity.”

Winder Boats says it is always looking to optimise the production process, so is constantly investigating new products and processes to refine construction further. In the meantime, whether you want a bulletproof trainer or a high performance race winner, it will have the boat for you.

For more details, contact David or Guy Winder on 01535 604980 or email david@winderboats.com.

Website: www.winderboats.com

If you want to drop by, the address is Winder Boats, Kensington Street, Leighly, West Yorkshire BD21 1PW.