Projects: Stronger, lighter, faster – using epoxy for powerboats.

Powerboat driver Bob McCarthy explains why epoxy is now his only choice – whether he’s racing his Formula 3 Bernico in Offshore circuit Racing or breaking water-speed records.

People often ask me what the experience of racing powerboats is like. I’ve been doing it for 25 years and I’m still not sure I really know the answer to that – or what I’m thinking when I’m on the water.

It’s very exhilarating, of course, and on a boat you feel you’re travelling so much faster than on land. I race my F3 Bernico now, so you might be doing 70mph in a boat that’s 19ft long and weighs just over 500kg.

But I think really it’s just about staying focused. We predominantly race on quite rough waters, so you need to read the water, always ready to trim the engine, correct the steering and so on. We race for about half an hour, sometimes lapping in just over a minute, with eight or so turns on each lap. Every section of the race is different – and ultimately I need to have total confidence in the boat that I’m using.

Why choose epoxy?

I use a boatbuilding company called Bernico, which is based in Belgium. They built a Formula 2 boat for me using PRO-SET® epoxy products for the 2010 season, and then in 2012 I moved to the Formula 3 model – which uses a smaller engine size – and at that point I started to talk to Bernico about using vacuum infusion with epoxy to build a Formula 3 boat, which they agreed to do.

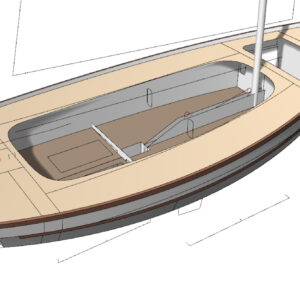

It was an interesting project. We used Formax quadaxial fibreglass cloth, a 12mm DIAB foam core and Compsys pre-formed stringers, all glued together with PRO-SET Infusion Epoxies.

There’s a misconception that vacuum infusion with epoxy is an expensive process, but if you look at the cost of polyester resin versus epoxy resin that doesn’t really stack up. We worked out that we’d need so much less epoxy than polyester – because you need less of it to create a strong, reliable craft – that it worked out as only slightly more expensive to use epoxy.

What you get for that cost is a much lighter and stronger construction. It’s lasted much longer than my old polyester boats without showing any signs of stress, so in the long run you save money. Older polyester boats used to barely last a season.

It’s also a much more rigid boat. I initially described it as like driving a car with the tyres pumped up too hard! It’s not enough discomfort to warrant doing it a different way: for racing, if you can make something rigid without it breaking, that’s very good.

Breaking speed records

I know from experience just how resilient epoxy products are. Every year I take a boat up to Coniston Water in the Lake District to take part in Coniston Power Boat Records Week.

In 2010, I took the Formula 2 boat, fitted with a 370hp Formula 1 engine I’d been lent from merc-racing in Belgium. We broke the British record for an outboard immersed propeller monohull that year – averaging 103mph.

The boat was absolutely fine, even after that. It was brand new at the time and still looked brand new afterwards. It handled beautifully.

If it can take that sort of speed and show no signs of stress, then I’ll happily put my trust in epoxy.

About Bob: Bob McCarthy lives in Devon, England. His many achievements include winning the A Class Championship in 2004 and the French V200 Championship in 2012. He is chairman of The Offshore Circuit Racing Drivers Association.

Discover the full range of PRO-SET Infusion epoxies that have helped Bob break records and win championships.

Find out more about Bob and the Offshore Circuit Racing Drivers Association.