Projects: Racing the dream boat: the Bernico F3 Xtreme

Durable and lightweight are the holy grail of offshore powerboat racing but can you have both? Absolutely, says driver Bob McCarthy – with the help of epoxy, that is. We find out how Bob created his dream F3 Xtreme with master boatbuilder Nico Bertels, owner of Bernico International in Belgium.

There’s a real skill to Offshore Circuit Racing. Guiding these rockets around multi-lap tight circuits calls for an emphasis on acceleration, balance and handling, so that they twist and turn over the water. It’s exhilarating, challenging, competitive and quite simply – as driver Bob McCarthy puts it – “really good fun, or I wouldn’t keep doing it!”

Bob’s a well-seasoned racer along offshore waters. His Circuit Racing career began in 1989 and he has many an accolade to his name. This includes his 2010 achievement of breaking the British speed record for an outboard immersed propeller monohull, by racing at a staggering 103mph.

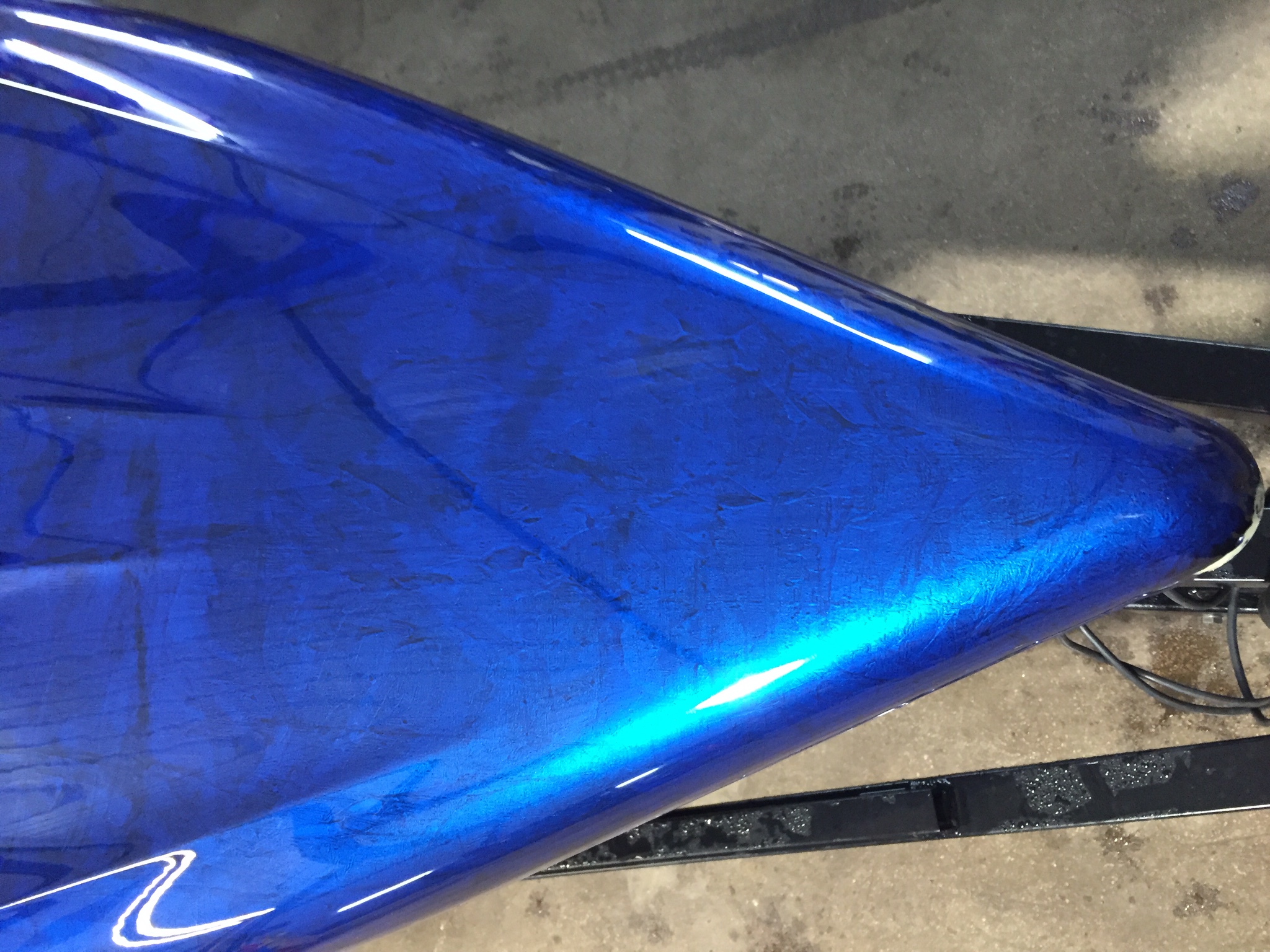

Now in his 26th season, Bob competes in a 2015 F3 Xtreme built by Belgian boatbuilder Bernico International. At 19ft long and 6ft wide, this sleek and shiny V4 Yamaha-powered monohull is strong, light (just under 500kg) and designed to shoot across the water, reaching an average top speed of 75.2mph in the 2015 Coniston Power Boat Records Week.

However, the F series wasn’t always so light. As Bob explains, “I’ve been working with boatbuilder Nico Bertels of Bernico International since 1996 and we built my first powerboat in a standard polyester sandwich.” The result was an extremely durable craft but one which was as heavy as it was strong – and heavyweight crafts don’t win races. “We did manage to get the amount of polyester resin used down from 450kg to around 300kg,” says Bob. “However, to really fly, I wanted a boat that was both light and robust.”

“I always wanted to use epoxy to save weight while adding strength. I knew I’d have a much lighter, tougher and better-performing boat as a result.”

Engineering a boat with both of these qualities called for Bob and the Bernico International team to change tack, moving away from traditional polyester towards epoxy resin. “I always wanted to use epoxy resin to save weight while adding strength,” says Bob. “I knew I’d have a much lighter, tougher and better-performing boat as a result.”

Epoxy: strength without compromise

It was a chance meeting between Bob and David Johnson of West System International at a UK marine exhibition that led Bob to choose PRO-SET® epoxy for the job. “We got talking about how there doesn’t have to be a compromise between strength and weight,” says Bob. “With epoxy, you can create components that are lightweight, durable and capable of reaching top speeds without showing any signs of stress.”

At the 2009 Marine Equipment Trade Show (METS) in Amsterdam, Bob introduced Nico to David. “I was about to order a Bernico F2 Xtreme for the 2010 season and Nico agreed to build it in PRO-SET® infusion epoxy for me,” recalls Bob.

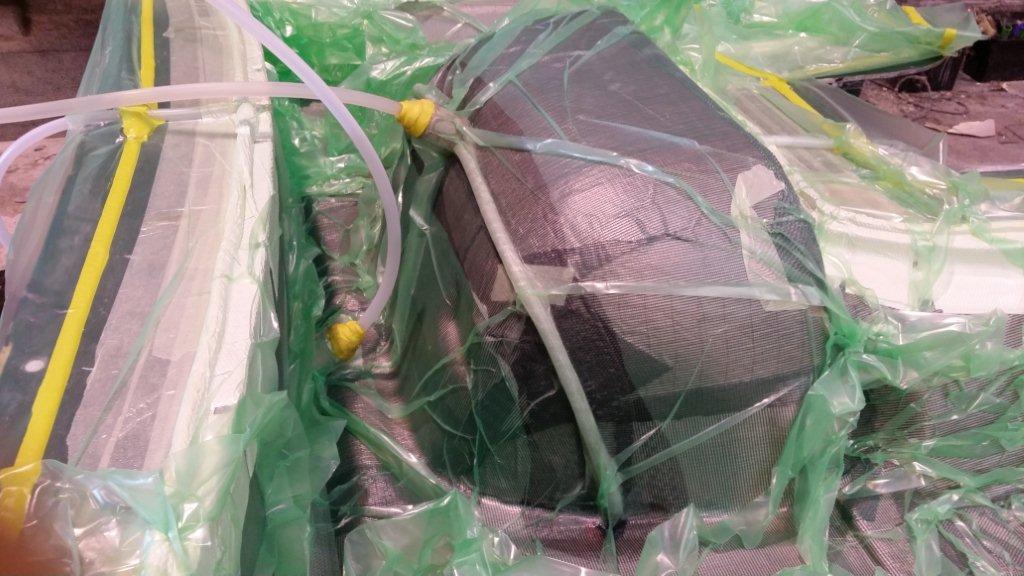

The Bernico team built the boat using hand lamination and vacuum bagging. Then in 2012, Bob moved to the F3 Xtreme model – a smaller and more agile boat – and started talking to Nico about using in-mould infusion techniques for the decks and hull.

“For me, epoxy infusion is clearly a much better way of building.”

Why the switch? “For me, epoxy infusion is clearly a much better way of building,” says Bob. “For a start, it’s much cleaner and safer. Unlike hand lamination, you don’t even have to physically touch the resin.”

In-mould infusion: stronger boat, faster production

In-mould vacuum infusion involves – as the name suggests – delivering epoxy within a mould via vacuum pressure. “It’s a much quicker process,” says Bob. “Once the moulds are set, the epoxy is vacuum infused. You need to spend time setting up the process but once that’s in place, it takes as little as a week to complete.”

For Bob’s F3 Xtreme, the Bernico International team used PRO-SET INF-114 Resin® in conjunction with PRO-SET INF-211 Medium Infusion Hardener® and PRO-SET INF-212 Slow Infusion Hardener®. These hardeners allow both the working time and the cure time of the resin to be adjusted, whether infusing a large or small, simple or intricate component.

“My F3 Xtreme takes a pounding – it’s bordering on cruel really! It shouldn’t stay together but it does – all thanks to epoxy.”

The result is superior strength, a faster ride and even greater resistance against impacts and abrasion – which, as Bob knows, is very important. “We race on pretty rough waters, so my F3 Xtreme takes a pounding – it’s bordering on cruel really! It shouldn’t stay together but it does – all thanks to epoxy.”

“For me it was a no-brainer”

What about cost; isn’t epoxy more expensive than polyester? According to Bob, this is a common misconception. “While epoxy resin and hardener are marginally more expensive, bear in mind we used around 300kg of polyester resin for my last polyester boat versus just 2o0kg of PRO-SET INF Epoxy for my latest F3,” says Bob. “The result is a much stronger and faster product. For me it was a no-brainer.”

Bob spent three years racing his original 2012 F3 Xtreme without a hitch. Sadly that boat’s life ended, not on the water but in a workshop fire. His current F3 is almost one year old and is, he says, ‘as near as damn it’ identical to its predecessor – save for a custom marble-effect paint job, courtesy of Bob’s youngest son David of Warcombe Auto Bodies.

Testing her mettle

So what’s next for Bob and his F3 Xtreme? Though she’s still relatively new to the racing scene, Bob is set to test her mettle with a packed 2016 season of events. Bob will then make his annual trip to Coniston Water in the Lake District in November to take part in Coniston Power Boat Records Week. “It’s the finale to the racing season,” he says. “Last year’s 75.2mph record is the one to beat!” Bob, we wish you the best of luck!

_____________________

Hailing from Devon, Bob McCarthy is chairman of the Offshore Circuit Racing Drivers Association (OCRDA). To find out more, visit the OCDRA website (http://ocrda.info/).

To read about the F3 Xtreme and other Bernico models, visit the Bernico International website. Or watch the F3 Xtreme in action here (http://bernico.be/en/gallery/video/?gallery=9).

Discover the full range of PRO-SET INF Epoxy Infusion products on the West System International website.