Projects: Product design using epoxy for casting

Keith Moir, a lecturer in product design at City of Glasgow College, tasked his students with creating some eye-catching plant pots using ENTROPY RESINS® (given its eco-friendly, sustainable credentials), an excellent epoxy for casting.

Wessex Resins and Adhesives’ Sam Oliver judging the students’ creativity at the Faculty of Creative Industries at Glasgow City College in February 2019.

Just what is possible using ENTROPY clear casting resin and a polyurethane (PU) mould?

Lots! These are just three of the 22 designs of succulent holders the students created between them.

Sustainability and low environmental impact are key concerns amongst people. For Keith (who lectures in product design) castable eco-epoxies were high on his wish list. When he heard about ENTROPY RESINS, he realised that it was exactly the epoxy for casting that he needed.

His students were tasked with designing and casting tealight holders or mini cactus plant pots and Wessex Resins and Adhesives was asked to help with product sponsorship, technical expertise and judging the results.

Keith took his students on a road trip of dramatic architecture for inspiration, including the V&A design museum in Dundee and the Transport Museum in Glasgow.

To make the designs the students were taught how to make moulds using vacuum forming and then casting with the bio-resin. Fillers were used to reduce the amount of epoxy used. In essence the project was about sustainability, hence the reason for using a bio-based product.

Students learnt to handle the ENTROPY CCR epoxy resin and also to measure the exact amounts of resin to hardener. Note the scales being used for an exact ratio by weight.

Sam Oliver flew up to Scotland to judge the results.

He later took the three winning pots to JEC World to showcase the students’ designs.

The three winning designs had a prime position on the Wessex Resins and Adhesives’ stand at JEC World, a show attended by some 44,000 composites professionals from 112 countries.

Sam says: “I was genuinely blown away by what the students had managed to make and how creative they had been. I was impressed with the thought that had gone into the whole production process, from concept to execution. We were proud to display the three winning examples at JEC.”

Here are some images from the course and the type of course assessment piece that students make to accompany the task.

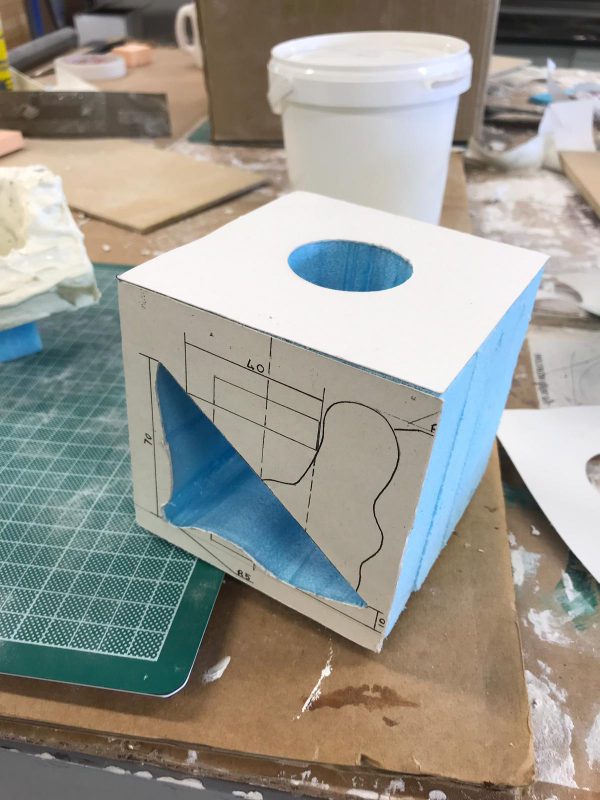

Inspired by a visit to view modern architecture, the resulting design is envisaged in 3D and drawn onto the laminated block of PU foam.

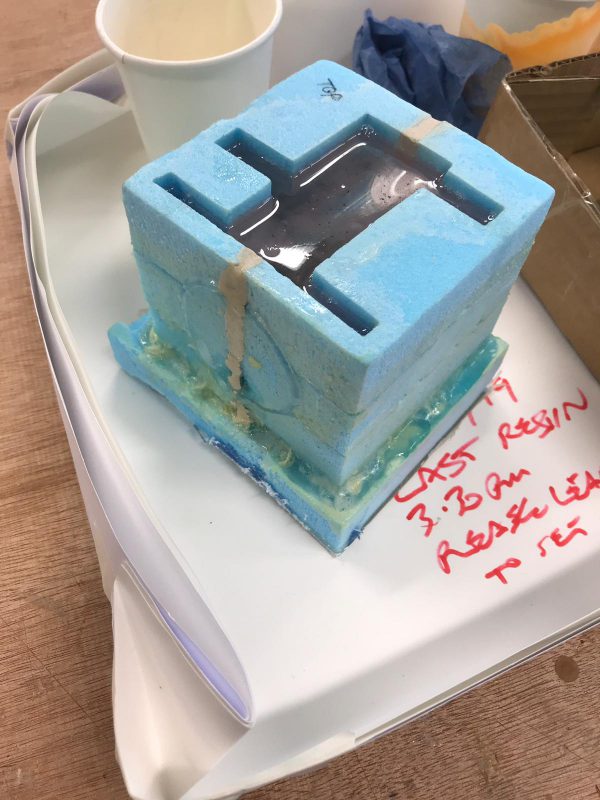

In this design, the sections have been hollowed out and the ENTROPY CCR epoxy resin has been poured as it’s the best epoxy for casting. Some students added pigments to the resin for a combination of colours.

A released piece, showing that the possibilities are endless.

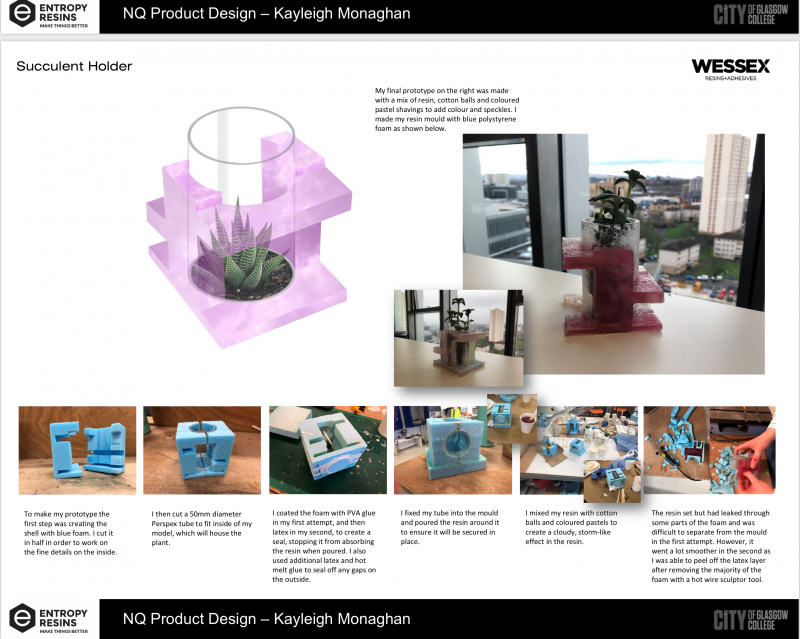

This is how the work is presented for the course assessment. This excellent piece from Kayleigh Monaghan shows a clever mix of colours and angular shapes whilst the narrative clearly describes the design and production process needed to make it. Students must be able to not only think in 3D and take the design right through to completion but also be able to express their thought processes to a prospective client.

For more information on ENTROPY RESINS visit: https://wessexresins.co.uk/top-level-articles/entropy