Projects: Black Marlin – Jan Andersen’s 10m carbon-fibre trimaran

The best way to make a cruising yacht with a performance ‘far above normal’ is to use multiple hulls infused with West System International’s PRO-SET epoxy. Then use composites to create an equally light rig and interior. Fit an electric motor for green propulsion and the result is Jan Andersen’s awesome Black Marlin.

Black Marlin is a 10m carbon-fibre trimaran designed and built by Jan Andersen using PRO-SET materials.

Boat builder Jan Andersen is the one-man band running Vision Boats, a company that specialises in building fast and eco-friendly sailing yachts in carbon composites. His yard is based in Scandinavia and Jan himself has ranged far and wide to gain the experience needed to create his ‘ultimate’ yacht. These have included a return trans-Atlantic crossing and a voyage from New Zealand to the Mediterranean. So far he has created two trimarans, with a third currently under construction.

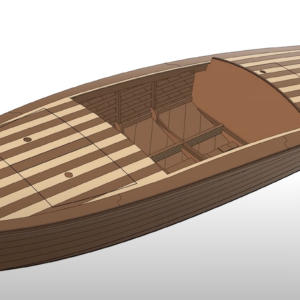

The first was built in cedar and called Barracuda and was the test bed for his next yacht, Black Marlin. Named after the fast and ferocious fish (one of them famously took down a fishing boat off the coast of Florida) Black Marlin is a 10m trimaran with two outer hulls that can fold inwards for road transport and docking. What is so remarkable is that the use of PRO-SET infusion epoxy and carbon fibre has created a 30ft yacht that weighs just 1460kg ready to sail.

There has been no scrimping on accommodation either to achieve this startling performance. The interior is nicely finished with wooden veneers and the main saloon table can seat eight. The hull is so easily driven that it is powered by an electric motor recharged from renewables, so Black Marlin is very much a self-refueling yacht.

“I am interested in using and developing the latest knowledge and materials to create the best products,” Jan writes on his website. “My great passion for multi-hulls has made trimarans my specialty.”

In addition to building fast sailing machines, Vision Boats also creates carbon masts and booms for other yards using PRO-SET epoxy and female moulds. “The new method we are using gives us a very high-quality spar, with a carbon fibre content of between 65% – 75%,” Jan said. “This delivers a top-quality finish, but with low weight and high tensile strength.”

Black Marlin has already proved itself with a series of voyages and race wins, including line honoursat the Ohavetrundt event in 2016 and winner of the Fyncup in 2017.

Here are some examples of her infusion build and the finished yacht in action.

For more details, or to order a custom-built mast, contact Jan Andersen at: www.visionboats.com

Black Marlin

Specifications (Racing rig):

Type: Modern carbon trimaran

LOA: 10.0m

LOA (folded): 11.5m

Length main hull: 9.6m

Beam (deployed): 7.8m

Beam (folded): 3.55m

Beam main hull: 2.54m

Draft (swords down): 2.10m

Draft (swords up): 0.4m

Airdraft: 16.5m

Weight (ready to sail): 1460kg

Mainsail: 46m2

Foresail: 20m2

Gennaker: 85m2

CE Category: B

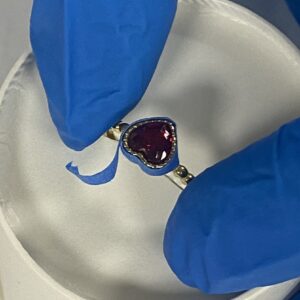

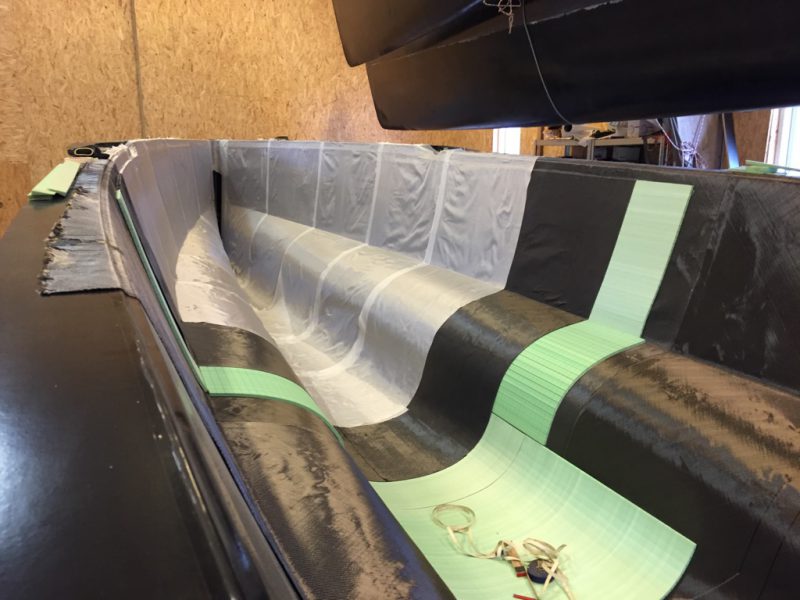

The hull is laid up using carbon fibre reinforced with foam core, square-cut to allow it to be curved to the female mould shape.

The carbon and core is overlaid with fabric and then infusion pipes added.

“I infuse with PRO-SET INF-114 Resin with PRO-SET INF-212 Slow Hardener as I find this combination makes it very simple to mould a hull. It also gives me a very light but strong moulding,” Jan said.

The interior is very roomy and nicely finished. Composites with veneers have made the furniture attractive but also lightweight. Note the carbon table.

Looking aft, the lack of a big diesel frees up space for a berth beneath the cockpit. Black Marlin is powered by an electric motor instead.

At speed. The outer hulls fold back for transport by road and the solar panel along the roof tops up batteries for the motor and lights.

David Johnson of West System International has sailed on Black Marlin:

I had the privilege to sail on Black Marlin at Ballen Havn near Svendborg last year whilst on a technical support visit to Hans Fokdal from HF Marine, our distributor in Denmark. We were lucky enough to sail with Jan Anderson, Black Marlin’s owner/designer/engineer and constructor www.visionboats.com.

At 0730, we were on board and sailing sweetly and effortlessly upwind at between 9 and 12 knots in a soft breeze. Jan is a fascinating character. He served his apprenticeship in traditional wooden boatbuilding so it’s surprising that every item on Black Marlin that could be made in carbon and PRO-SET epoxy composite is constructed of these materials. Black Marlin is Jan’s own design and build, which is something of an achievement given the confines of spare time!

With clear carbon finishes on many of the components, there is nowhere for a lack of skill and expertise to hide. The finish is exquisite. The mast, in itself a thing of structural beauty with real aesthetic appeal, is constructed in female tooling and infused with epoxy via vacuum. This is a process that Jan himself developed and has since been adopted by the builders of www.dragonfly.dk for the performance versions of its popular trimaran range.

After our sail, we motored back to the mooring alongside the marina using a little electric outboard and Jan folded Black Marlin in 60 seconds reducing the beam (and the mooring cost) by two thirds.

Jan is currently working on a smaller trailable design.

David Johnson, Sales Director, West System International and sometime yachter.