Projects: All about: Cantiere Navali De Cesari

Cantiere Navali De Cesari (De Cesari Boatyard) on the north-eastern coast of Italy is an illustrious name in international boatbuilding circles. They’re also one of the biggest fans of epoxy you’ll find. In this profile of the WEST SYSTEM® epoxy users, owner Paolo De Cesari tells us how the boatyard’s humble beginnings have led to hundreds of projects.

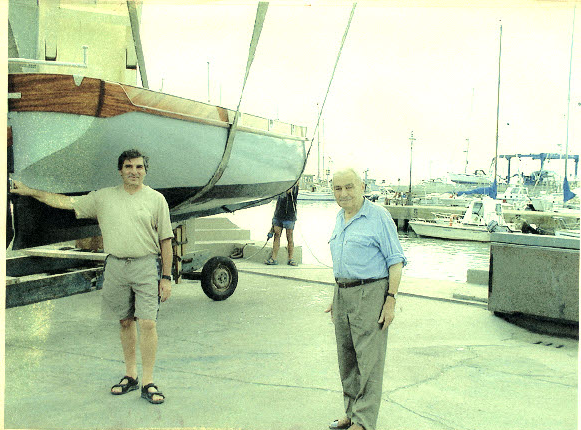

The De Cesari boatyard was started by my father, Adriano De Cesari, in the 1940s. Today, we have a reputation across Europe and around the world for producing striking, one-off designs. However, we started out quite simply.

My father was always a great boating enthusiast and had been building boats since the early 1930s. He worked for a number of shipyards and studied at nautical school, before a stroke of luck in 1947 gave him the opportunity to buy a 150m2 shed next to his home in Cervia. That’s when the Cantiere Navali De Cesari was born.

“We’ve built more than 370 boats of all types – naval boats, as our name suggests, but also speedboats, catamarans, Venice water taxis, cruising sloops and much more.”

Since that date, we’ve built more than 370 boats of all types – naval boats, as our name suggests, but also speedboats, catamarans, Venice water taxis, cruising sloops and much more besides. I joined as a shipwright in 1961, but it wasn’t for another nine years that I was to design my first boat; her name was Carmen and she was a 9m motorboat.

In the early days, we followed traditional construction methods and used heavy wood planking. Today, all De Cesari boats are entirely constructed using a crossed laminate structure, comprising three to five layers of 4-8mm thick planks. This makes the wood far more workable and our boats far lighter. It also means we can build much longer boats; some of our designs are 30 metres long.

The days when epoxy was new

It was back in the 1970s that we first started using epoxy – right when it first came out. Kaufman, our engineer, told me about this ‘new technology’ that wasn’t known in Italy at the time. He actually flew from Florence to New York to get hold of some, picking up a 25kg can of WEST SYSTEM epoxy resin and a 5kg pack of WEST SYSTEM epoxy hardener to bring back in his luggage with him. We tested it and loved it straight away.

Epoxy is great because its intrinsic properties protect the wood against moisture. This can completely remove the risk of the wood deteriorating, making for extremely durable boats. It also creates very strong bonds. We use WEST SYSTEM products for absolutely everything, including laminating, gluing and filling all parts of our boats inside and out (from the hull, keel and superstructure, to furniture and other areas of the interior).

I remember the very first boat we used WEST SYSTEM epoxy on. It was Luni, an 11 metre sailing boat that Kaufman designed. You can still see the boat today, in Chioggia harbour; it’s been renamed ‘Sula’ and it’s still in perfect condition.

Visit Cantiere Navali De Cesari at SINISTRA PORTO 9 – 48016 Milano Marittima – RA. www.cantierenavaledecesari.it

If you’d like your boatbuilding knowledge profiled on epoxycraft, contact us.