Trade Secrets: 10 myths about epoxy: cured!

Maybe you’ve thought about using epoxy products for a project but heard a rumour they’re not good enough in some way? In part one of this myth-busting series our very own Guru of the Gooey Stuff, David Johnson, ‘cures’ a few myths about epoxy resin.

Myth 1: Epoxy doesn’t stick to polyester

I hear this a lot. However, it’s common knowledge within established boatyards and yacht surveyors that the best means of effecting a robust, long-lasting glass fibre repair on a polyester or vinylester hull, is to use epoxy. In fact, a well-executed epoxy repair finished with a polyester gel coat is superior and longer-lasting than a well executed polyester repair. The only conditions are that the epoxy needs to be thoroughly cured, well abraded and scrupulously clean. Polyester gelcoat is not recommended for finishing repairs below the waterline. Areas below the water line would normally be finished with 3-4 coats of epoxy prior to using a bottom paint.

This is because once epoxy is cured, it’s dimensionally stable and will not shrink. A typical polyester repair can end up being thick and bulky, plus the edges can shrink and telegraph through – but if cured properly, epoxy won’t do this at all.

In a boatyard, you’d use heat lamps to ensure the cure is sufficient but if you’re doing it yourself as a DIY project, you’d leave seven days for a full cure. This ensures the epoxy isn’t still reacting when you apply the polyester gel coat over the top. You’ve also got to make sure you thoroughly abrade the epoxy repair before you apply the top coat.

Myth 2: Epoxy is more expensive than polyester

Yes, that’s correct. Epoxy costs more per kilo than polyester. However, the fact is, you won’t use anywhere near as much epoxy as you would polyester resin. You’ll also use less fibre and other materials too.

Within the scheme of an epoxy composite boat build, for example, you’ll need far less epoxy to build a strong hull than you would if you were building the same size boat in polyester. This is because cured epoxy is much stronger than polyester resin. You can afford to use less fibre with it too because the sheer strength of the epoxy will make the fibre you do use much stiffer.

For example, a 12mm boat hull in polyester resin could easily be reduced to 4mm in epoxy and would be incredibly strong but also quite flexible. In fact you could reduce the skin even more to 2mm and put a foam core in – laminating over the back of the foam to create a sandwich – for a structure that’s just as strong but even lighter. Essentially, it’s possible to engineer an epoxy boat to be both strong and light whereas with polyester you’d have to choose between one or the other.

So, even though epoxy can cost 2 to 3 times more than polyester, you’ll typically end up spending far less on structural materials on an epoxy boat. If you’re building a boat for speed, especially, I think this is an absolute no-brainer.

Myth 3: epoxy isn’t as good as polyester for repairs

It’s a strange myth, this one, because I’m not quite sure where it comes from. Yes, polyester resin is incredibly strong but when it comes to repairs, epoxy is so much better than any other resin system.

For one thing, epoxy repairs don’t shrink. Polyester shrinks because it contains styrene and those styrene molecules evaporate when the resin cures. On a small area that might be ok but when repairing a big area it will add stress to your repair before you’ve even got your boat back out on the water.

The other thing, of course, is inhaling all that styrene when mixing and working with polyester resin is not good – especially if you’re working in an enclosed space. It can make you feel light-headed, dizzy, tired… and that’s just for starters. Epoxy , on the other hand, contains no VOCs (volatile organic compounds) and is cleaner and easier to mix, especially if you use the simple pump set that you get with WEST SYSTEM® products.

There’s also a lot of evidence to suggest that epoxy is far more water-resistant than polyester resin, which is important for boat repairs that are below the water line.

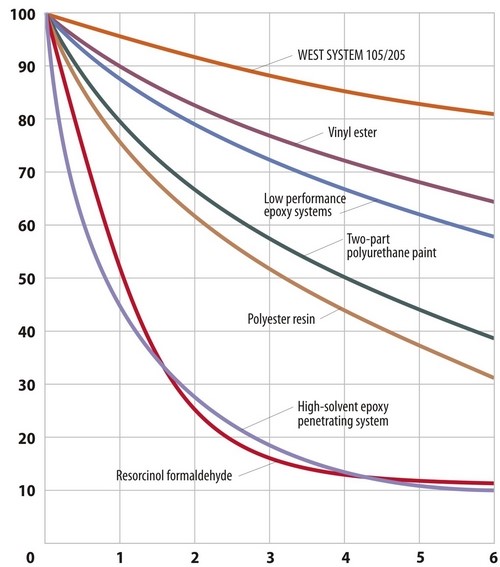

It’s generally accepted that a polyester bond is about 20% weaker than a bond made with epoxy. However, if you want to get really scientific about water-resistance, many years ago our American cousins did an experiment on the “moisture exclusion effectiveness” of epoxy (and all sorts of other coatings) on wood.

It was in a lab and under very specific conditions but WEST SYSTEM 105 Epoxy Resin® with 205 Fast Hardener® came out on top, demonstrating more than 80% water resistance at 6 weeks of continued moisture exposure. After the same period of time, polyester resin was just over 30% water resistant. The speed with which the water resistance of polyester degraded also appeared to increase over time. (If you’re really interested, have a look at the graph in Fig 1, or read the whole report here.)

Myth 4: epoxy is more brittle than polyester

I’ve heard a few people ask if epoxy is brittle, especially when it’s used with wood. However, the chemistry of epoxy is such that it elongates to flex – even in a timber structure.

The typical elongation of polyester is between two and three percent, while with WEST SYSTEM epoxy it’s over four percent. This means that using epoxy will create a material that is far more resilient to constant loading and re-loading than polyester.

Take a lightweight dinghy, for instance; it will come under a lot of stress. It’ll be loaded time after time with dynamic loads from the water, the rig, the sails and so forth and if it’s built in polyester – which is not so good at elongating – it will microcrack. This results in a laminate that becomes softer and softer.

However, if you use epoxy it’ll be more resilient because it’ll stretch more. Post-curing the epoxy will also make it stronger and boost the elongation properties further still.

So, the simple answer to this myth is: no. It definitely isn’t!

Myth 5: Epoxy won’t cure in cold weather

I can understand where this myth comes from, although it’s still a myth at the end of the day. Our WEST SYSTEM® 105 epoxy with 205 fast hardener® will actually cure at temperatures of just 5°C but it’s far from the optimal temperature for working with epoxy.

Just think of epoxy being a bit like honey. If you put it in the fridge it gets viscous and difficult to spread on your toast. In the case of epoxy you might not be able to wet out glass cloth quite so easily, or it might be harder to achieve the desired consistency when mixing epoxy with fillers. There’s also the risk that coatings go on too thickly, creating a subtle exotherm which can lower viscosity rapidly and increase the risk of running.

So what can you do to work successfully with epoxy in colder weather? The first thing you can try is warming up the epoxy (think of the honey example again). You can also create a tented area and use a small blow heater to increase the temperature where you’re working. That way the epoxy will be much easier to work with and you’ll get the best possible results and finish.

And the perfect temperature for working with epoxy? That has to be t-shirt temperature, meaning that if you’re comfortable working in a t-shirt you’ve got it right. For those who need a figure, let’s say 15°C!

Myth 6: Epoxy won’t stick underwater

This is definitely a myth. Some years ago we heard from a customer who tried to get rid of some left-over epoxy by flushing it down the toilet. It cured and stuck to the toilet pan and he eventually cracked the toilet trying to break up the epoxy with a chisel.

When it comes to emergency hull repairs and the like, we definitely wouldn’t recommend using epoxy below the waterline. However, WEST SYSTEM products might just buy you some time in the case of an emergency. We’ve actually had some success by applying some of our G/flex 655 product to a fibreglass plate and carrying out temporary emergency repairs under the water.

For this reason, we think more of our customers should pack G/flex® 655 epoxy and fibreglass sheets as part of their essential equipment on board. It’s one of those things that you hope you never need but it could be as vital as a pair of flares one day in an emergency situation.

Myth 7: Epoxy is only good for wood

Wrong! Whilst it’s true that WEST SYSTEM® epoxy was initially developed in the US for use with wood, it is a general purpose marine epoxy – and the product has been evolving constantly ever since.

Epoxy is now the material of choice for all manner of applications, from GRP builds and repairs, to fairing cement and aluminium hulls. It’s not just used for marine work either, we have customers who use our epoxy for repointing their houses, or for making decorations and even artwork with items set in cured epoxy. It’s even used on tube trains, buses, aeroplanes – the sky (or your imagination) really is the limit.

Just one caveat here is that different substrates need to be prepared differently to achieve great results with epoxy. We have a huge amount of literature on how to use epoxy with different materials – get in touch if you need support on a specific non-wood project.

Myth 8: Epoxy won’t stick to plastic

False again! There’s a WEST SYSTEM product specifically for this and it’s called G/flex® epoxy. There are lots of reasons why it delivers better results with plastic than traditional WEST SYSTEM 105 epoxy®.

First, I should say that you need to flame treat your plastic surface to get good adhesion with any epoxy product. By passing a flame incredibly quickly across the surface, without even heating the plastic, you create an oxidised surface that can be wetted out with the epoxy, rather than the plastic surface repelling the epoxy.

With the surface ready, G/flex epoxy delivers amazing results. It is much more elastic than other epoxies, so it can flex with the plastic and tolerate shocks and impacts. Just as a comparison, a 10cm length of regular WEST SYSTEM epoxy can stretch to 10.4cm before it breaks, while G/flex epoxy will stretch to 13cm. It’s a huge difference and really important for strong, long-lasting results with plastic.

Myth 9: Epoxy’s pot life is too short

It’s true that epoxy waits for no man, but planning effectively and working the right way can give you a longer working time.

One important thing to mention here is that we calculate a working time of 20 minutes based on mixing epoxy resin and hardener in a small paper cup. This is standard practice which allows you to compare working times between manufacturers, but you can buy more time by mixing your epoxy in official WEST SYSTEM® mixing pots, which are short and stout.

By reducing the depth of epoxy in the mixing pot, you also reduce the intensity of the exothermic reaction – which is why you get more working time. If you could mix your epoxy in a roller tray, you’d get even more time, but achieving a good mix would, of course, be impossible.

Another way you can extend your working time is by using WEST SYSTEM pumps. One pump of resin and one pump of hardener give you approximately 24 grams of mix, which is perfect for small jobs. With experience, you can work your way up to three pumps of each and still have time to work. As well as being the fastest way to measure out and mix epoxy, pumps help you work more cleanly, with no need to pour and weigh the epoxy resin and hardener.

Myth 10: Epoxy is harder to use than Polyester

When it comes to choosing a resin system, it’s definitely horses for courses and Polyester and Vinyl-Ester resins definitely have their place in boat building. Many times, professional boat builders have experience of working with both epoxy and Polyester and they find them both as easy to work with.

However, there are some reasons why epoxy might be a more convenient choice for amateur boat builders, DIY enthusiasts or anyone who hasn’t worked much with resin/hardener previously.

First, Polyester often comes in large packs, which might not be convenient or cost effective for all users. Second, WEST SYSTEM pumps make epoxy easier to measure out and mix, with no need to weigh Polyester and catalysts. Thirdly, inexperienced users may find Polyester more pungent than epoxy, which could be off-putting, especially if you’re working in a confined space.

So no, epoxy definitely isn’t harder to use than Polyester and it might even be easier for some people who are inexperienced working with different resin systems.

Learn more about the full portfolio of WEST SYSTEM epoxy products.

Thanks very much to David Johnson for another expert contribution. Look out for part 3 next month!

Looking for guidance and tips on how to use epoxy products for your boat build? Have a look at our full list of Trade Secrets.